Gear-shaving machine knife quick change mechanism

A gear shaving machine and tool technology, applied in the field of tool change mechanism, can solve the problems of axial displacement of nut 12, affecting cutting quality, time-consuming and labor-intensive, etc., and achieve the effect of fast tool change, compact structure and preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

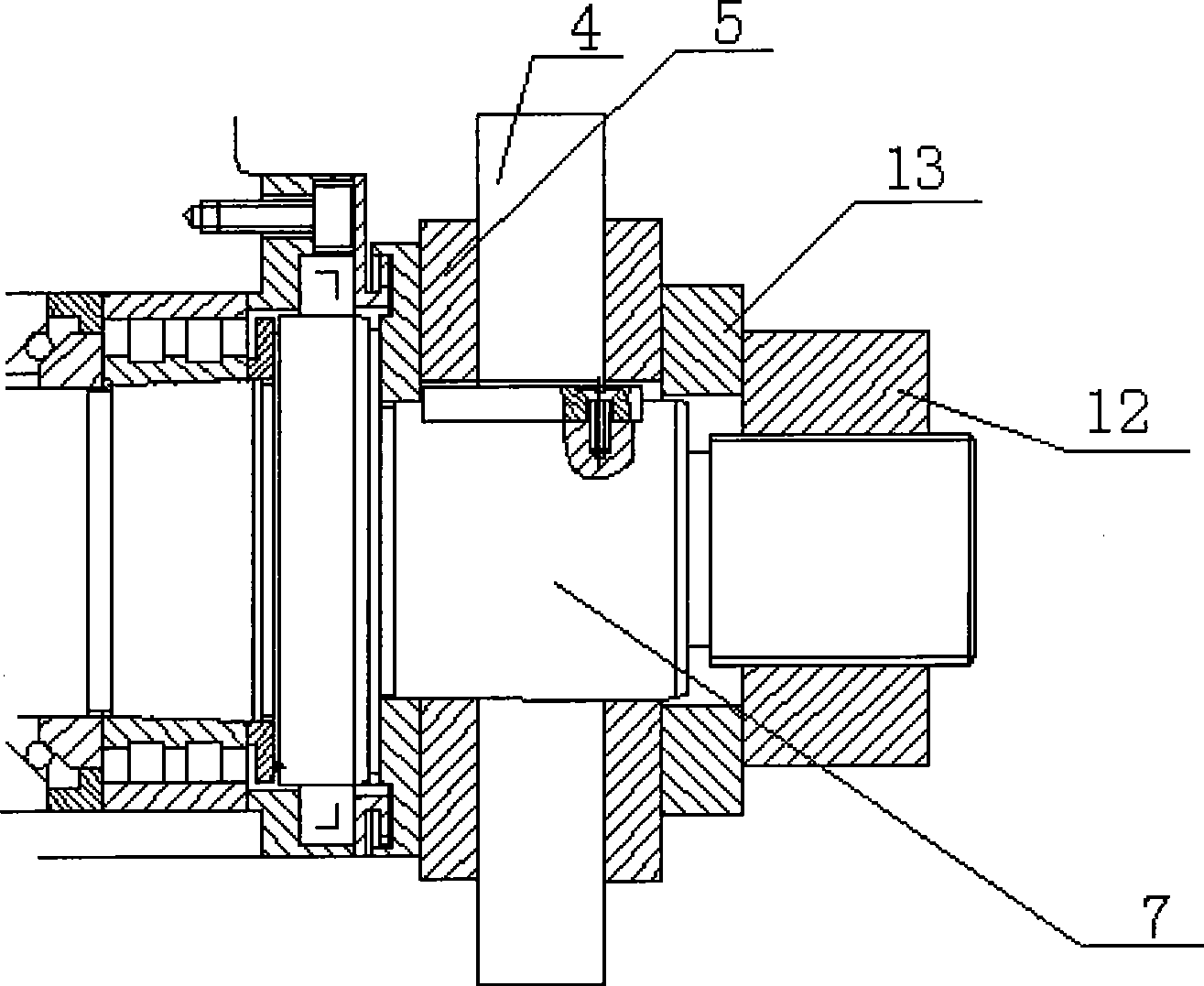

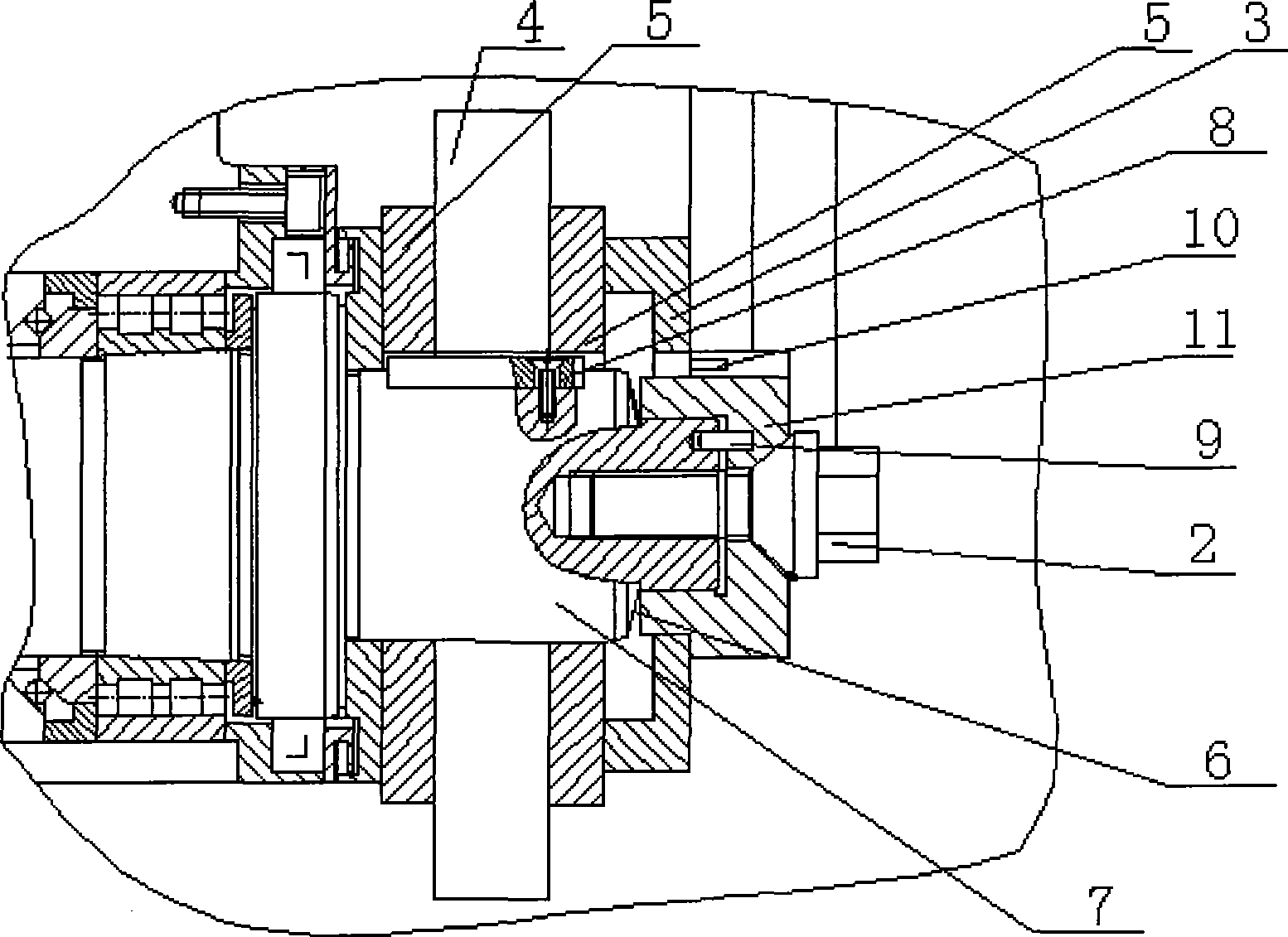

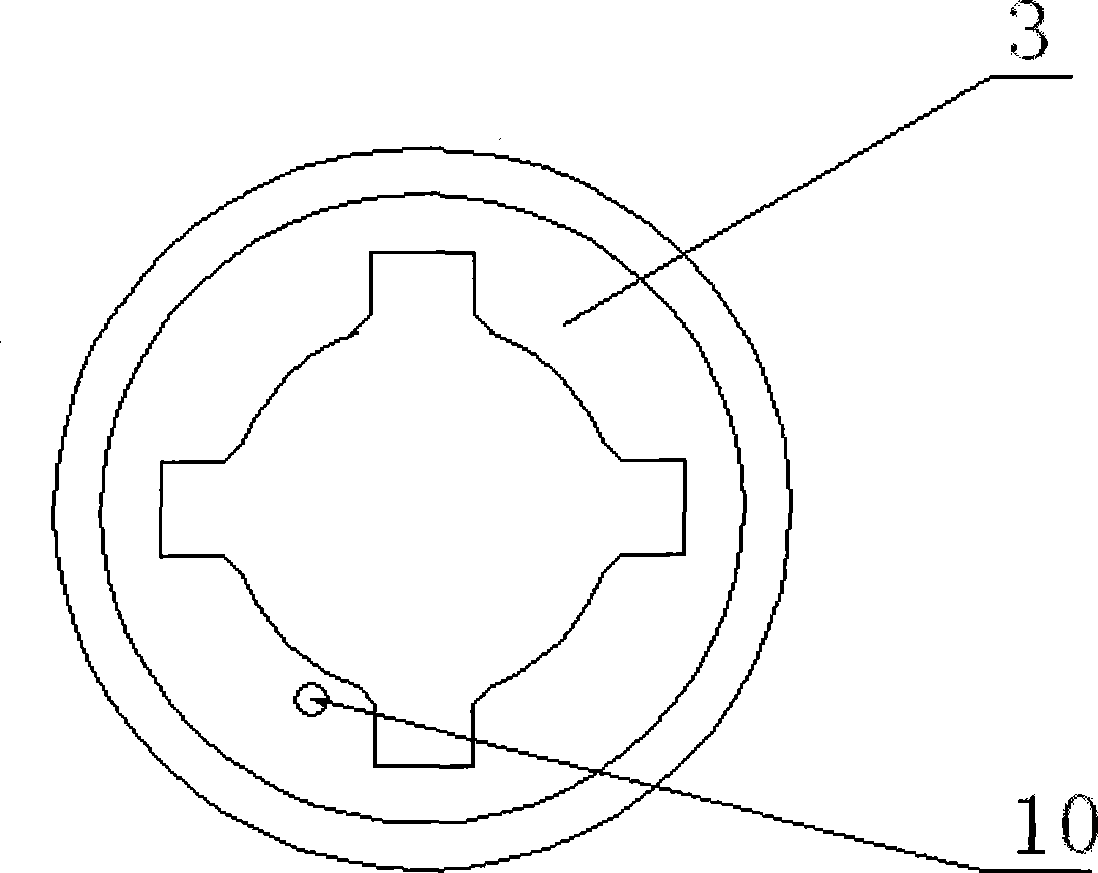

[0016] please see Figure 2 to Figure 4 , the tool quick change mechanism of gear shaving machine described in this embodiment consists of locking screw 2, quick release washer 3, razor 4, tool washer 5, disc spring 6, main shaft 7, flat key 8, guide pin 9, limit The pin 10 and the spline shaft 11 are composed of a razor 4 and a cutter washer 5 on the main shaft 7, the cutter washer 5 is located on both sides of the razor 4, and the razor 4 is fixed on the main shaft 7 through a flat key 8, and the main shaft 7 is a stepped shaft , its outer end is set with a spline shaft 11, and is fastened by the axial locking screw 2; the length of the spline on the spline shaft 11 is shorter than the length of the spline shaft 11 itself, and the end of the optical axis is close to the tool washer 5 ; The looper on the spline shaft 11 has a quick release washer 3 with a spline groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com