Brake forming mold for door casing of refrigerator

A bending forming and refrigerator technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of low production efficiency, time-consuming and labor-intensive equipment cost investment, etc., and achieve convenient manufacturing, improve production efficiency, and reduce production processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

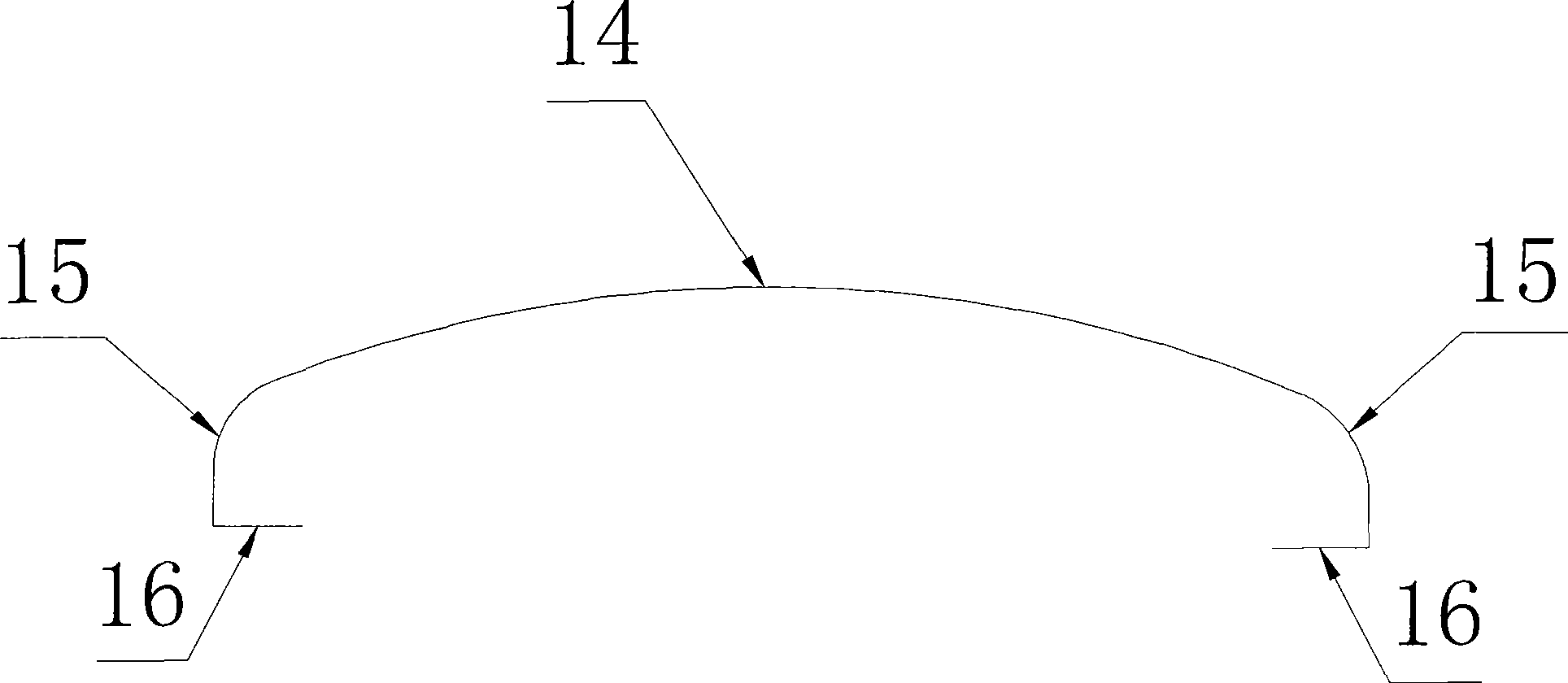

[0016] Example: such as figure 1 Shown is a schematic diagram of the cross-sectional shape of a common refrigerator door shell at present. The two ends of the body 14 of this refrigerator door shell have two sides 15 that are curved and transitioned in a circular arc. At the same time, the bottom of each side 15 also has a The flanging 16 of the conventional method needs to adopt multiple sets of molds to be carried out in several steps when processing this refrigerator door shell, which is time-consuming and laborious, and the equipment cost input is large, and the production efficiency is low. The object of the present invention is to provide a kind of bending mold that can process out this refrigerator door case at one time.

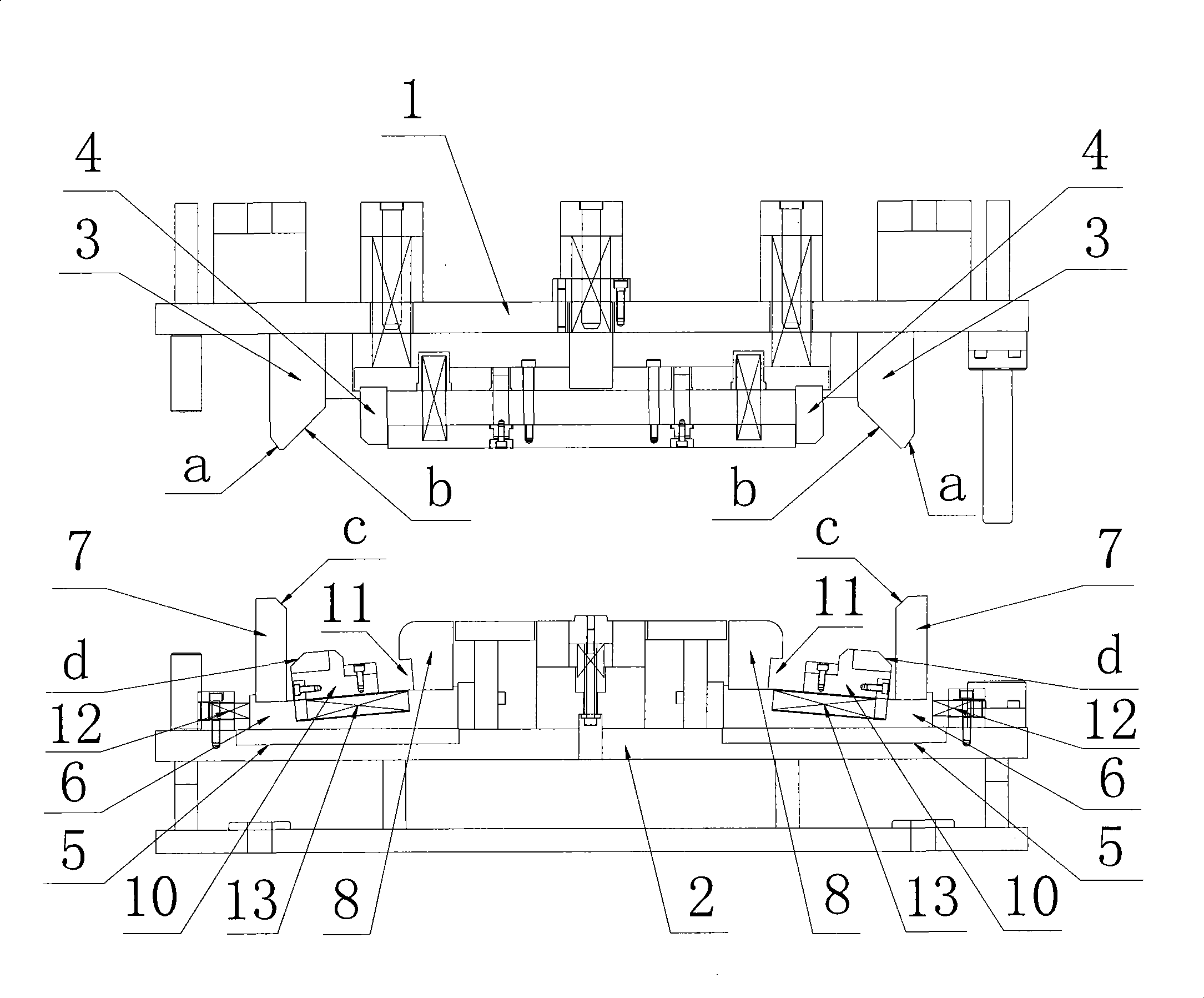

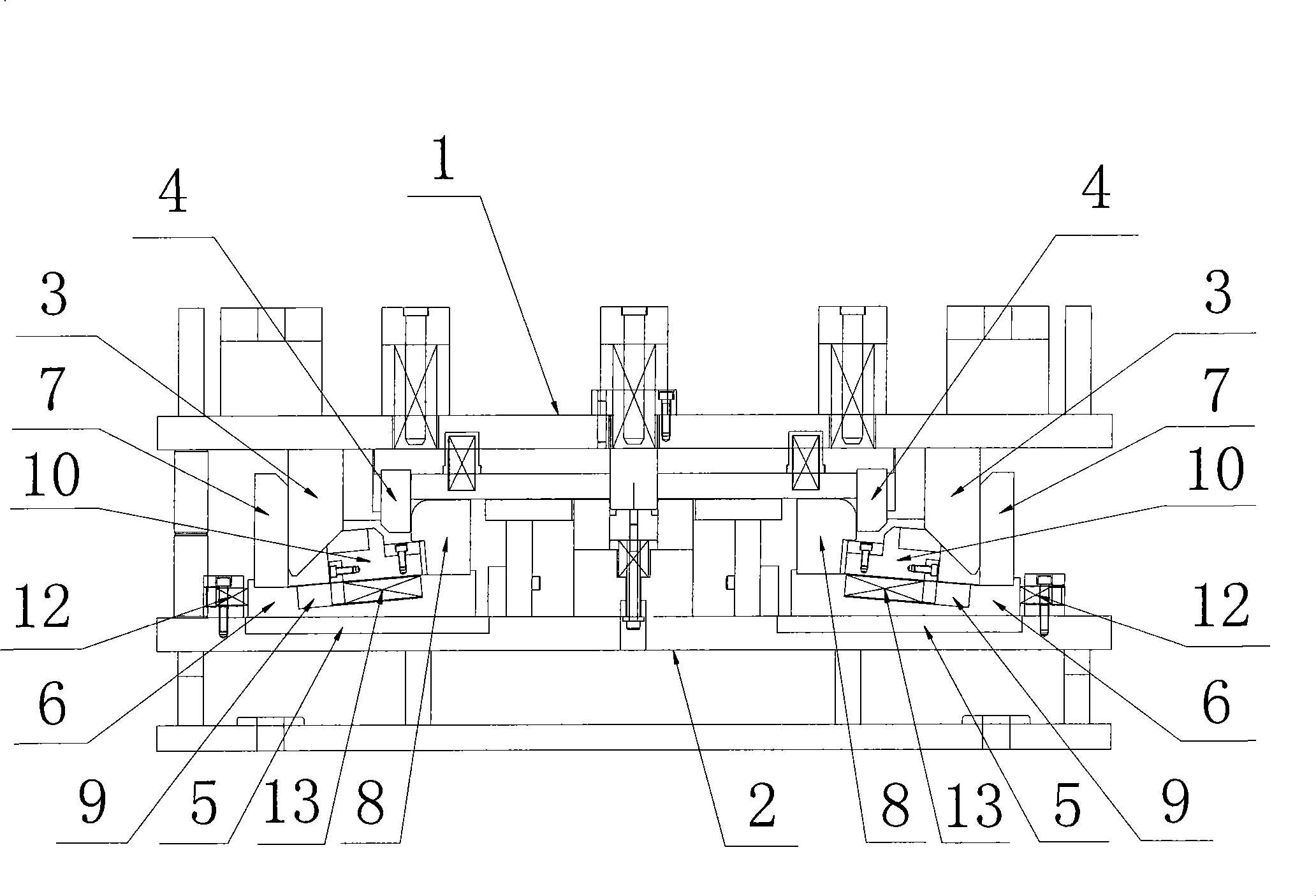

[0017] combine figure 2 , image 3 Shown is a specific embodiment of the refrigerator door shell bending forming mold of the present invention, which includes an upper template 1 and a lower template 2, and two upper driving blocks 3 and two upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com