Indentation testing instrument and indentation testing method

一种压痕试验、压痕深度的技术,应用在测试材料硬度、测量装置、仪器等方向,能够解决误差等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

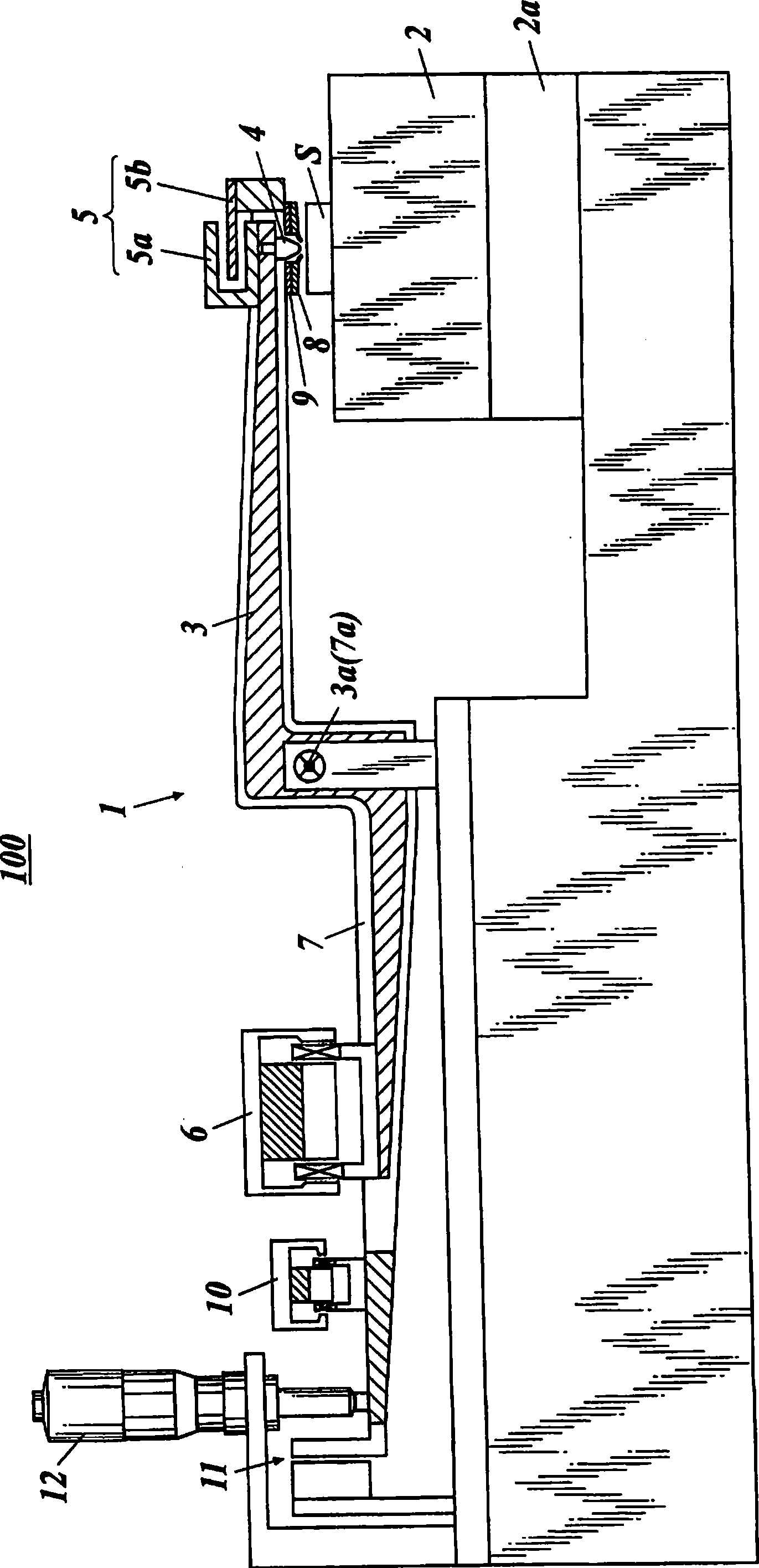

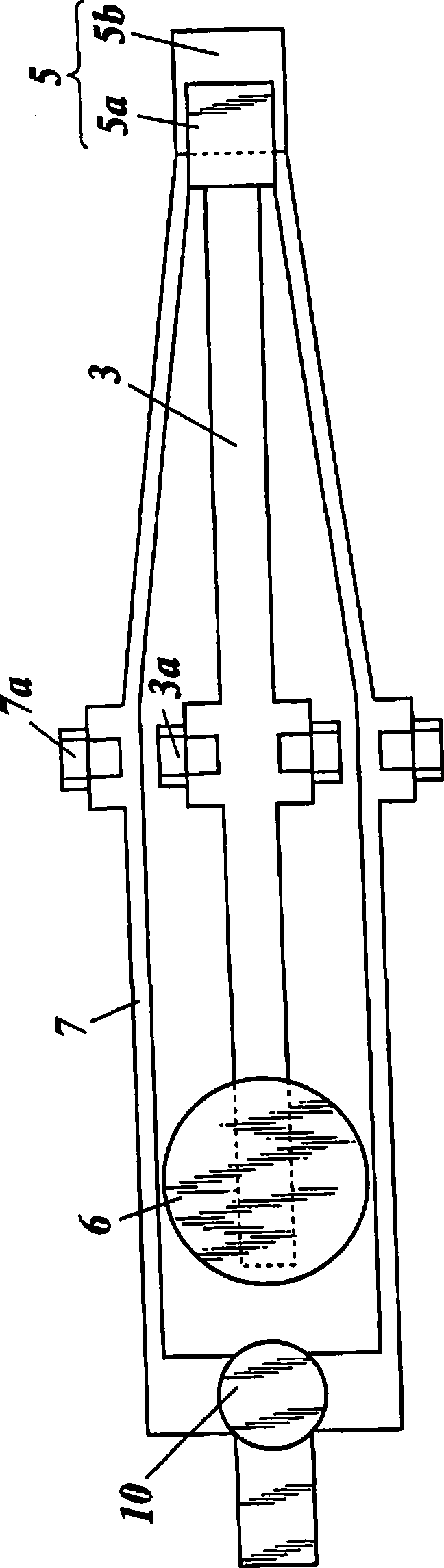

[0021] Hereinafter, an indentation tester and an indentation test method according to the present invention will be described in detail with reference to the accompanying drawings.

[0022] Incidentally, the indentation tester 100 of this embodiment is an instrumented indentation tester capable of continuously monitoring the test force (load) applied to the indenter 4 and the indentation depth of the indenter 4 .

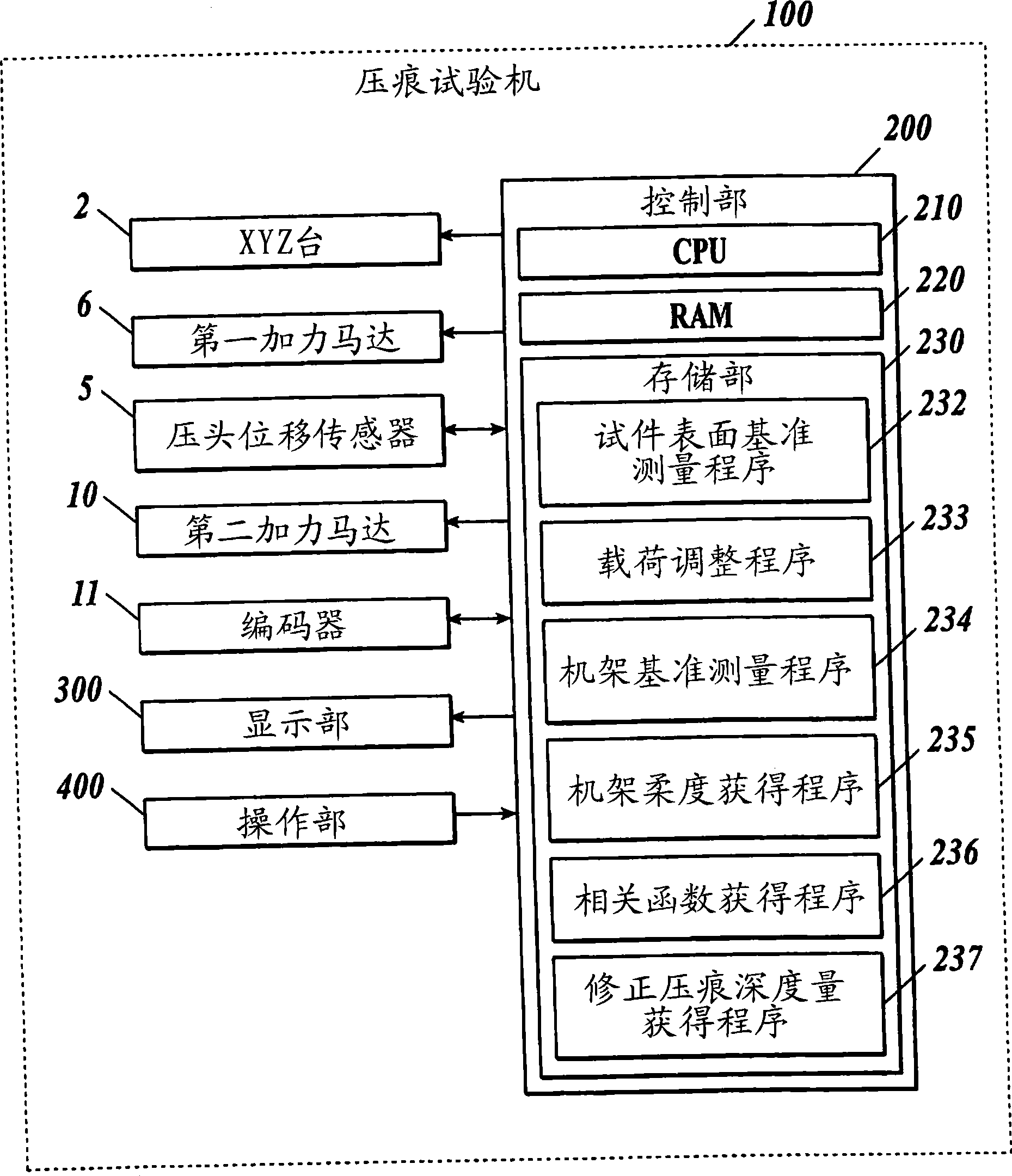

[0023] Such as Figure 1 to Figure 3 As shown, the indentation testing machine 100 is composed of the following: a testing machine main body 1 for applying a test force (load) to the test piece S; a control unit 200 for controlling each part of the testing machine main body 1; a display unit 300 ; and the operating unit 400 and the like.

[0024] The testing machine main body 1 includes: a test piece holding table 2 on which a test piece S is placed; a loading bar 3 pivotally supported by the testing machine main body 1; On the lower surface; as the displacement s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com