Packing case

A technology for packing boxes and beams, applied in the directions of packaging, transportation and packaging, loading/unloading, etc., can solve the problems of high work intensity, small buffer area, unfavorable on-site operation, etc., to increase equipment costs, reliable positioning, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

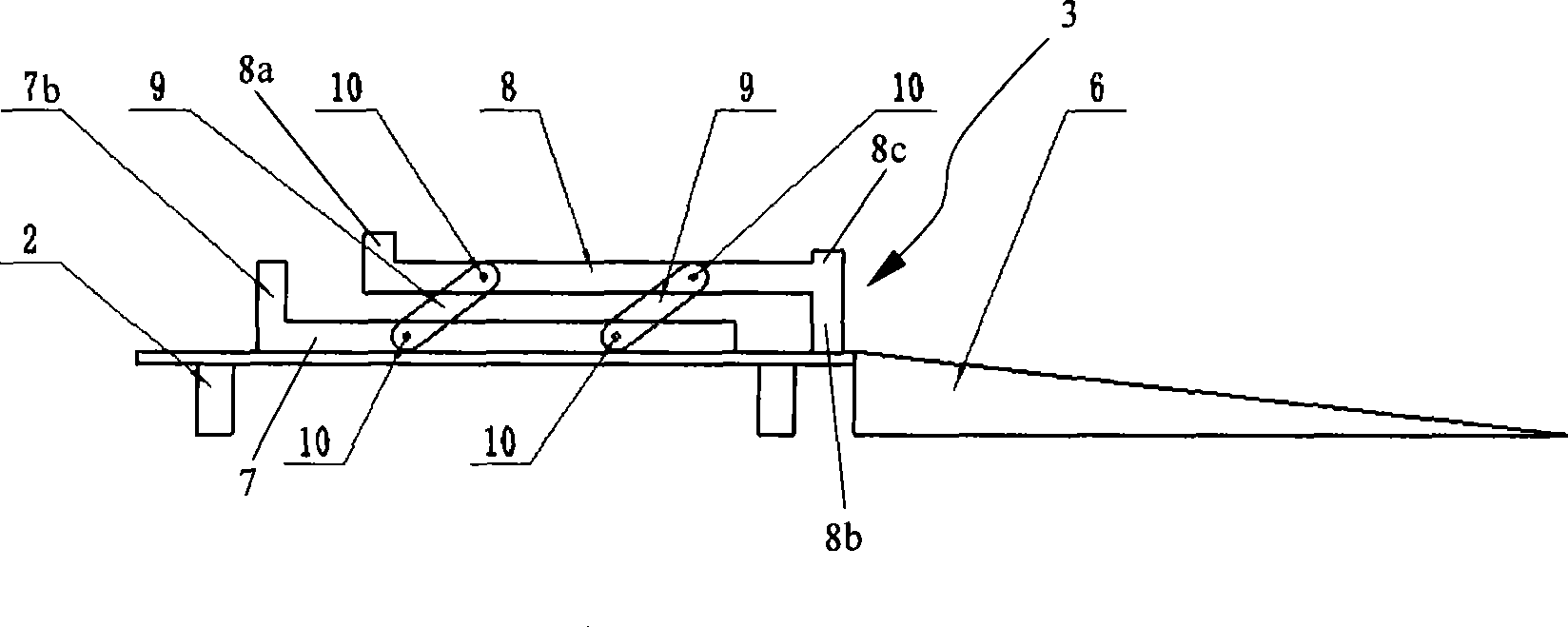

[0028] The exemplary embodiments of the present invention will be described below with reference to the accompanying drawings. In the drawings, the same components are denoted by the same reference numerals.

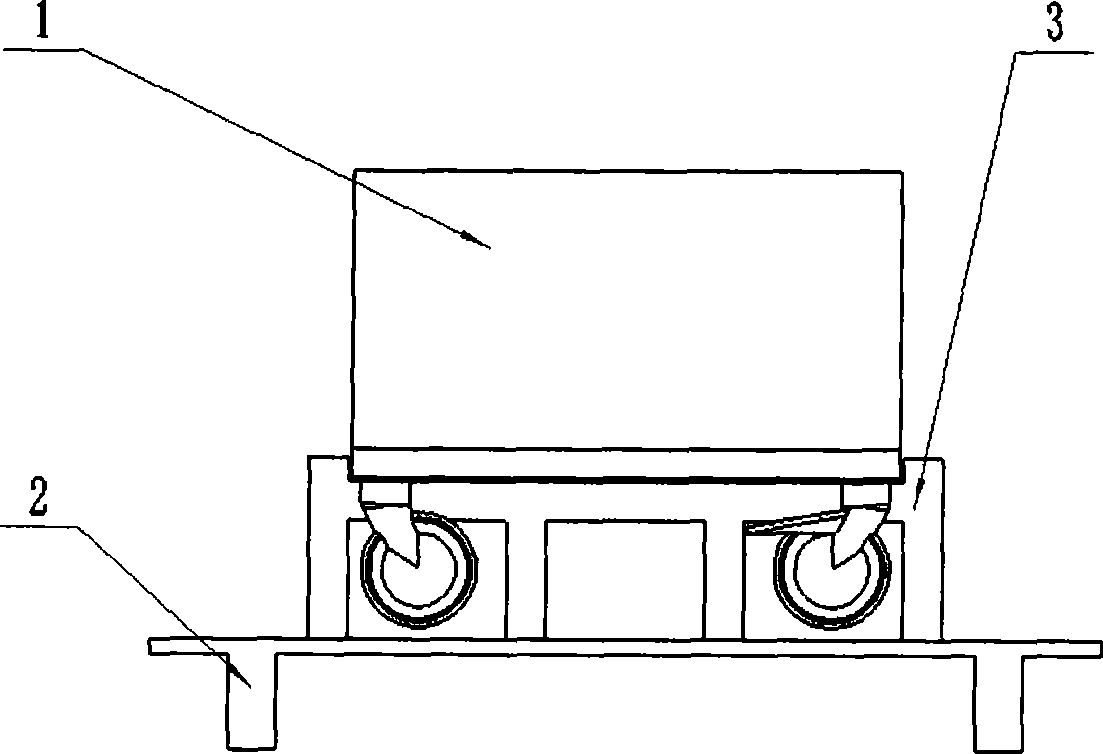

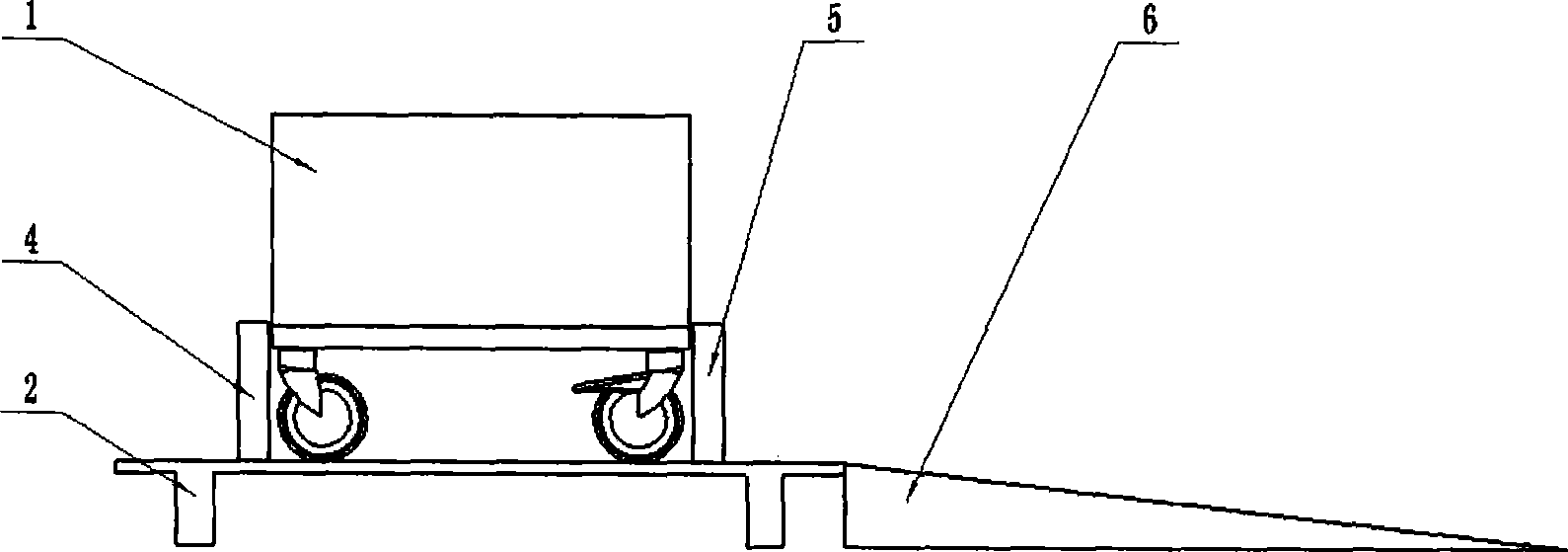

[0029] The structure of the packaging box of the present invention other than the box body is as image 3 As shown, it includes a packing box pallet 2, a cargo bottom bracket 3, which is arranged on the packing box pallet 2; the cargo bottom bracket 3 includes: a first horizontal support portion, which is arranged parallel to the packing box pallet 2; The rod 9, the two ends of the connecting rod are respectively pivotally connected with the packing box tray 2 and the first horizontal support part, and support the first horizontal support part from the first height to the second height, so The second height is higher than the first height. The first horizontal support portion of the cargo bottom bracket 3 can be fixed by a pair of left-right symmetric upper cross beams 8, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com