Protection device for in-mold decoration and method thereof

An in-mold insert injection molding and protection device technology, applied in the direction of coating, can solve the problems of poor stability and high cost, and achieve the effects of high stability, low cost and less interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

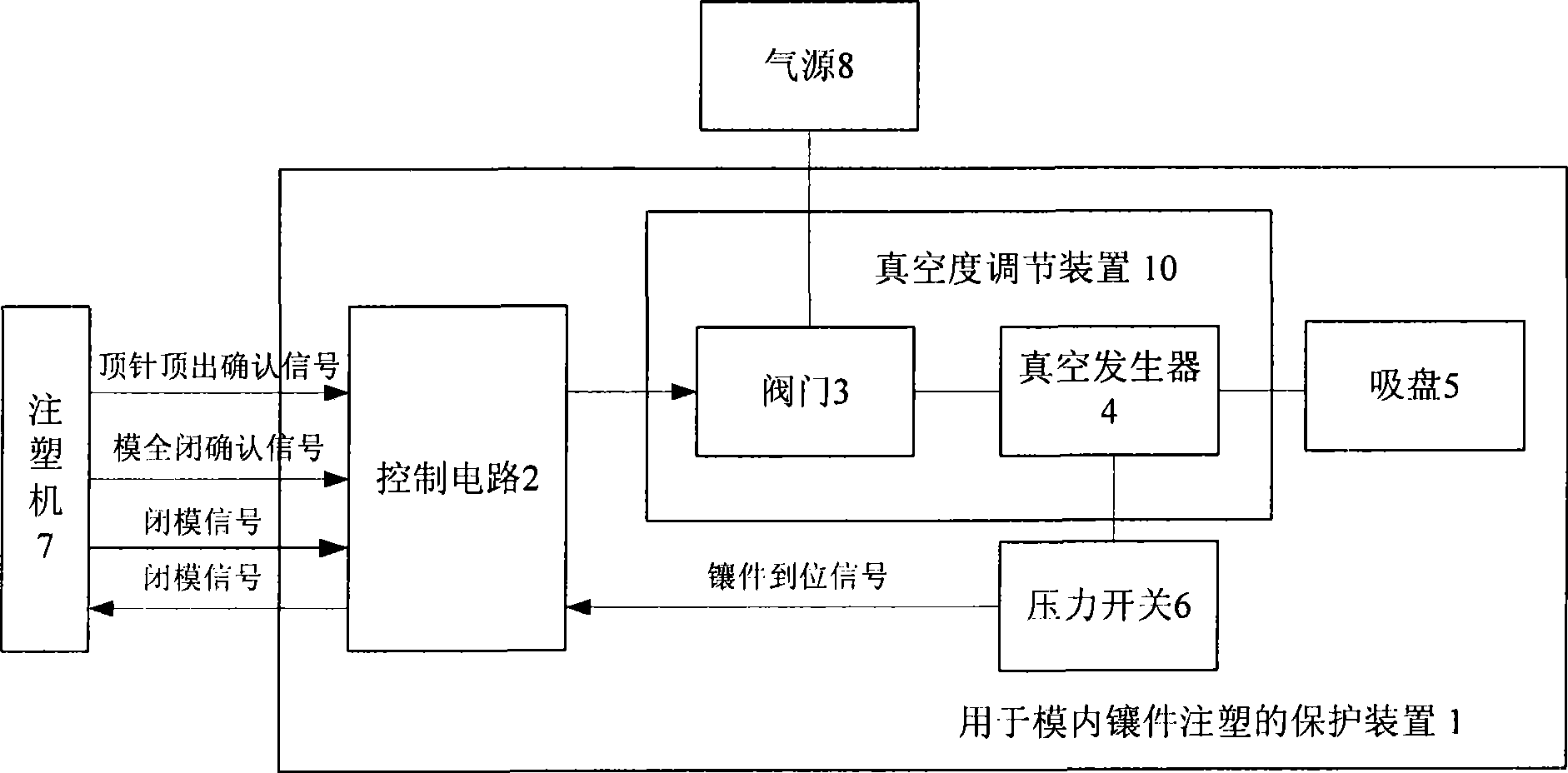

[0013] Such as figure 1 As shown, the present invention provides a protective device for injection molding of in-mold inserts, wherein the device includes a suction cup 5, a vacuum adjustment device 10, a pressure switch 6 and a control circuit 2, and the suction cup 5 and the pressure switch 6 pass through the air road and connected to the vacuum adjustment device 10, the signal output end of the pressure switch 6 is electrically connected to the input end of the control circuit 2, and the output end of the control circuit 2 is electrically connected to the control end of the vacuum degree adjustment device 10; the suction cup 5 is used For the adsorption insert, the vacuum adjustment device 10 is used to adjust the vacuum degree between the suction cup 5 and the insert, and the pressure switch 6 is used to detect the vacuum degree between the suction cup 5 and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com