Method for sealing and wrapping edge using fluoro-resin seamless film

A technology of fluororesin and fluororesin coating, which is applied in the direction of stove/stove bracket/shelf, special materials for cooking utensils, etc. It can solve the problems of wasting fluororesin raw materials, affecting the appearance of products, and uneven force on edge wrapping, etc., and achieves the goal of manufacturing The effect of cost reduction, material reduction, and uniform stress on the edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: With reference to Figures 1 to 5, the fluororesin seamless film encapsulation method in this embodiment includes the following steps:

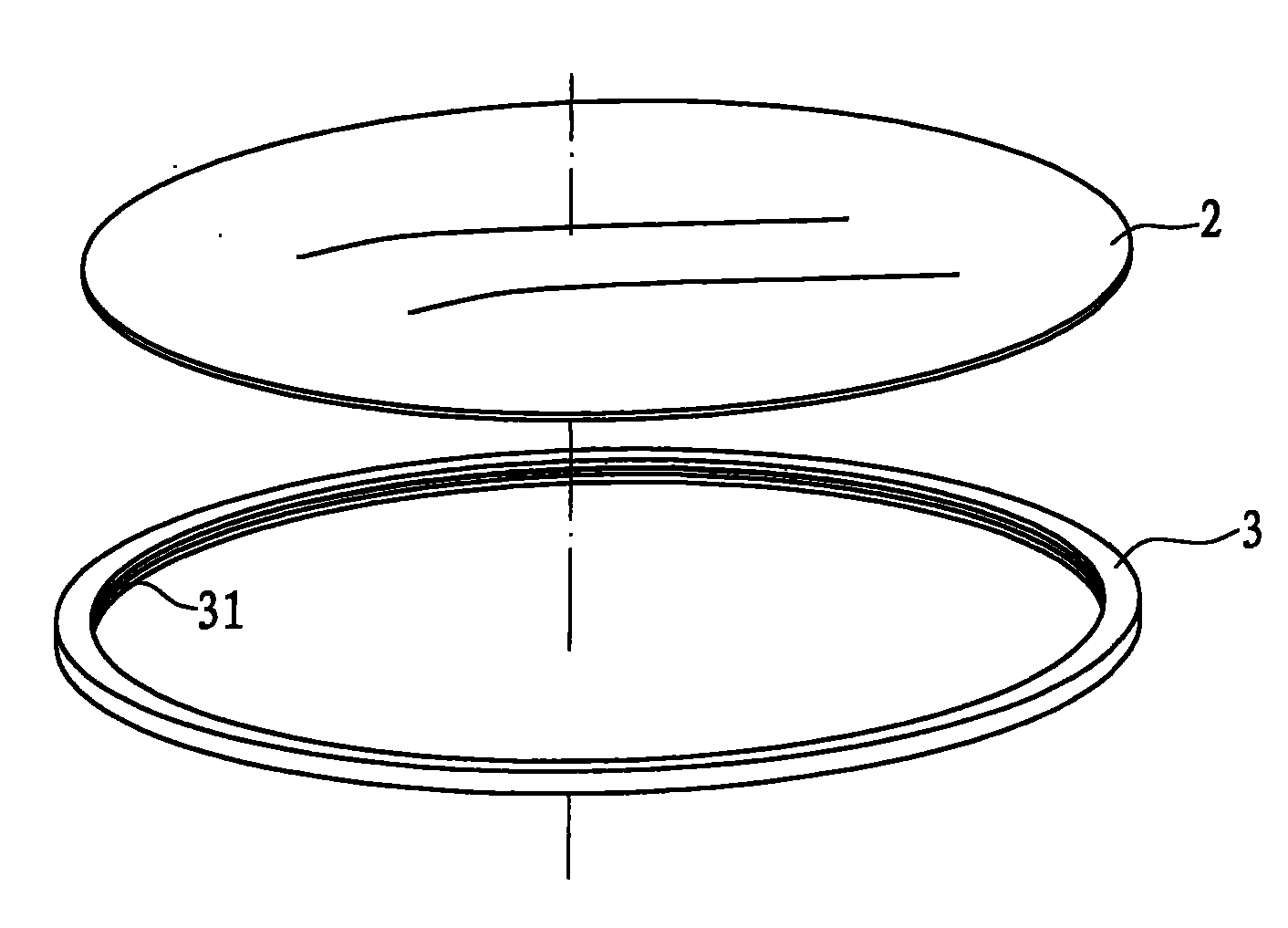

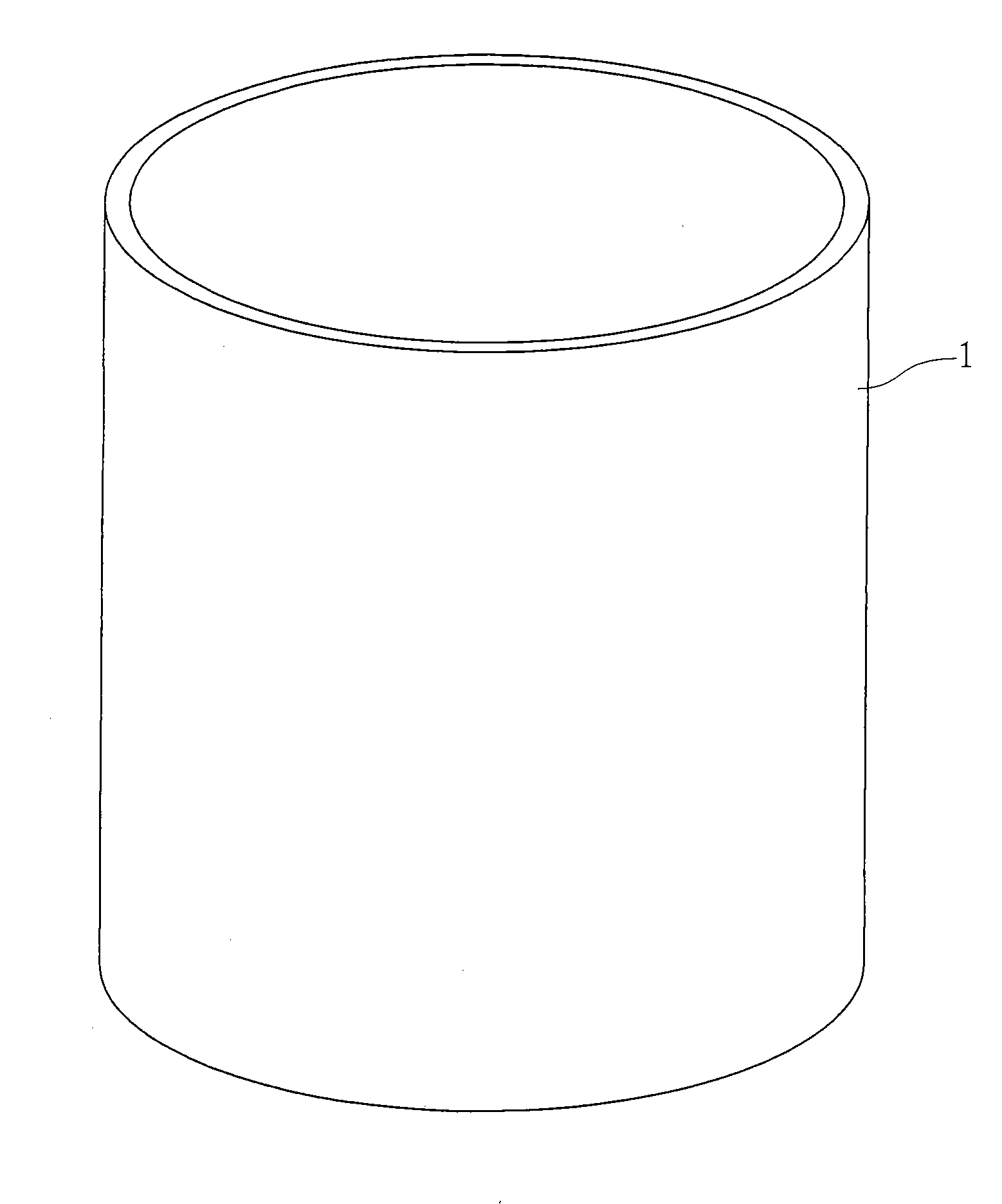

[0040] ①Put the fluororesin raw material into the mold, and add a coloring agent of 1 to 5% by mass to the fluororesin raw material. The coloring agent is high temperature resistant and consistent with the color of the fluororesin coating base fabric. It is obtained by one of the following methods Cylindrical body 1, as shown in Figure 1:

[0041] The first type is holding pressure, demoulding, and finally sintering the molded castings. The nominal pressure of holding pressure is 200~300kg / cm 2 ;

[0042] The second type is mechanical injection;

[0043] The third type is mechanical vulcanization;

[0044] ② Cut the obtained cylindrical body 1 into a ring 3, the axial thickness of the ring 3 after cutting is 0.1-0.3mm, and an annular gap 31 is cut on the inner wall of the ring 3, as shown in Figure 3;

[0045] ③ Cut the fluororesin-...

Embodiment 2

[0049] Embodiment 2: Referring to Figures 6, 7 and 8, the fluororesin seamless film encapsulation method in this embodiment includes the following steps:

[0050] ①Put the fluororesin raw material into the mold, and add a coloring agent of 1 to 5% by mass to the fluororesin raw material. The coloring agent is high temperature resistant and consistent with the color of the fluororesin coated base fabric 2. After one of the following methods Obtain the cylinder 1:

[0051] The first type is holding pressure, demoulding, and finally sintering the molded castings. The nominal pressure of holding pressure is 200~300kg / cm 2 ;

[0052] The second type is mechanical injection;

[0053] The third type is mechanical vulcanization;

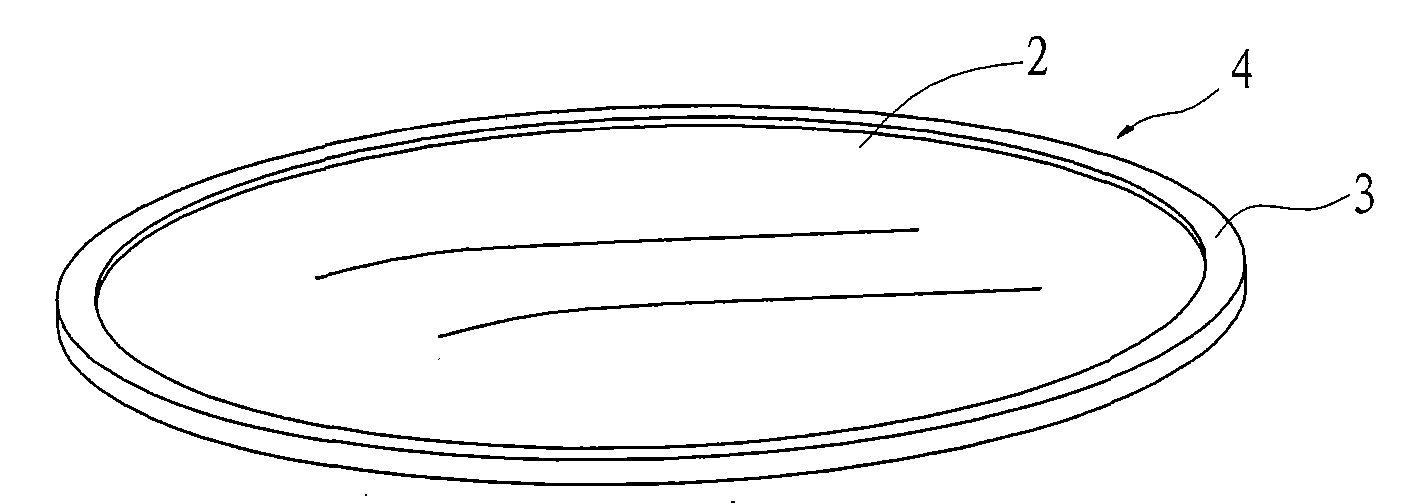

[0054] ② Cut the obtained cylindrical body 1 into a ring 3, and the axial thickness of the ring 3 after cutting is 0.1~0.3mm, as shown in Figure 6;

[0055] ③ Cut the fluororesin-coated base fabric 2 into a shape that matches the ring 3, and then take the cut fluorore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com