Aerofoil with high lift-drag ratio

A high-lift-to-drag ratio, airfoil technology, applied in the direction of instruments, calculations, electrical digital data processing, etc., can solve the problems of geometric and mathematical characteristics that cannot be changed, cannot be optimized, performance constraints, etc., to promote vigorous development, stall late, The effect of increasing the output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

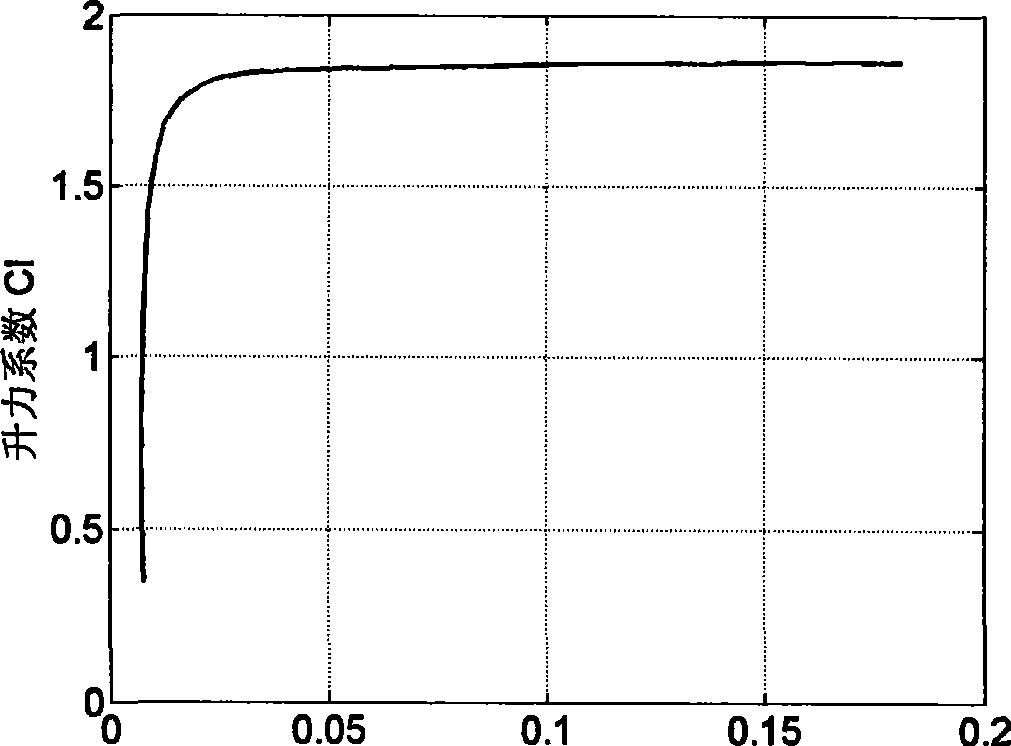

[0041] In the design process of the airfoil given in the embodiment, the first 6 items are selected according to the TAYLOR series thought and the convergence principle of the series function, and a certain relative thickness is selected to design the airfoil shape. The airfoil with a maximum relative thickness of 18% is given here. Table 1 gives the coefficients of the functional integration equation of this airfoil. Substituting these coefficients into the integration equation can obtain the shape of the airfoil. The maximum relative thickness is 18%, and the maximum relative thickness is at 27% of the chord length. See figure 1 .

[0042] Table 1 Coefficients of airfoil functional integration equation

[0043] Maximum Relative Thickness X1 x2 x3 x4 x5 x6 18% 0.1132 0.1328 0.0072 0.0261 0.0001 0.0189

[0044] The aerodynamic performance of the airfoil proposed by the present invention is calculated and analyzed by XFOIL software. Reynolds nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com