Double gate valve

A gate valve and valve body technology, which is applied in the field of double gate valves of vacuum equipment, can solve problems such as troublesome operation, short service life, and non-two-way sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

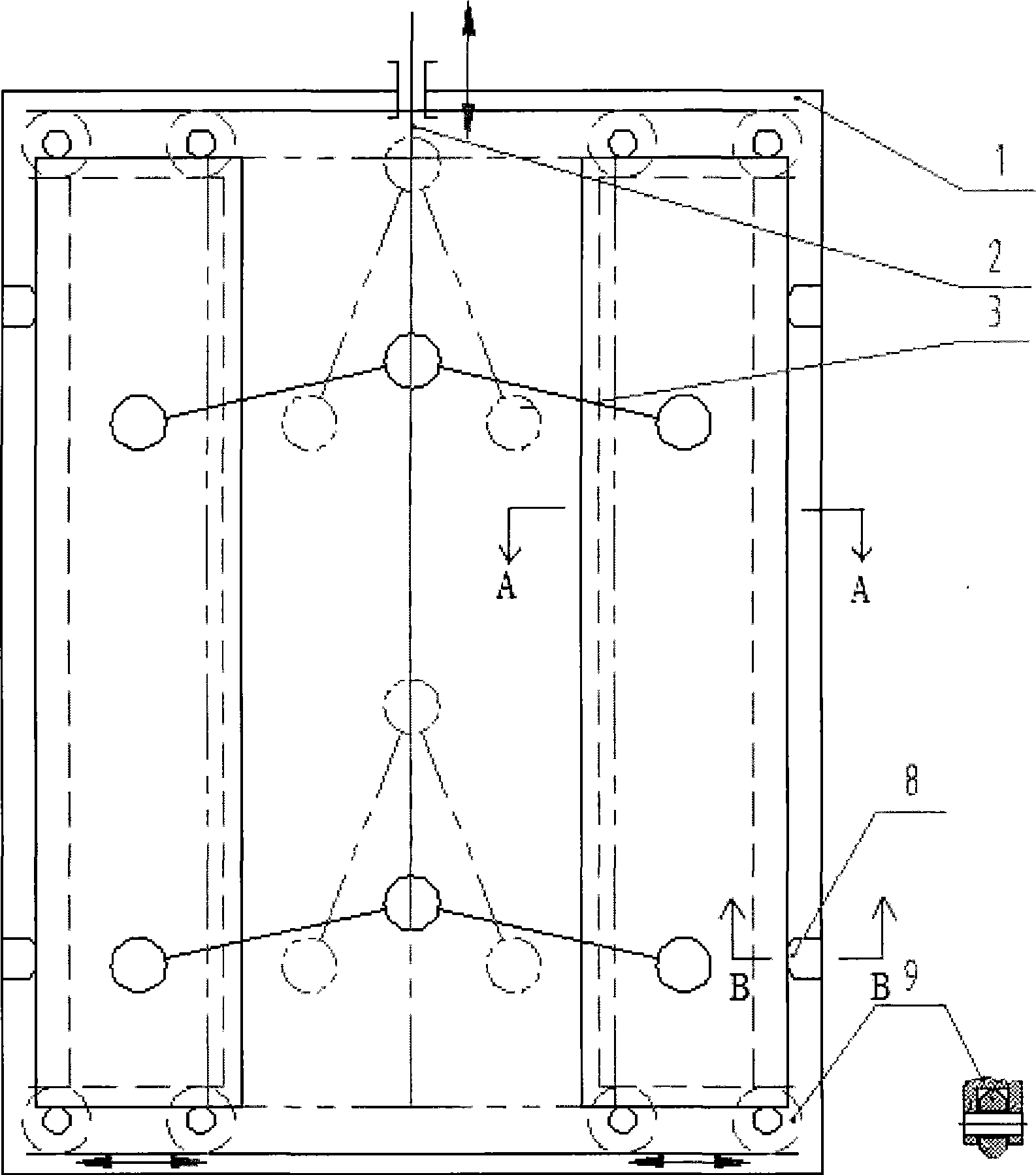

[0017] figure 1 is a structural schematic diagram of a double gate valve according to the present invention. The double gate valve includes a valve body, a driving device, a stop device and a valve device, wherein the driving device and the valve device are movably installed on the valve body, and the driving device is connected with the valve device to form a parallel A quadrilateral mechanism, the stop device is installed on the valve body.

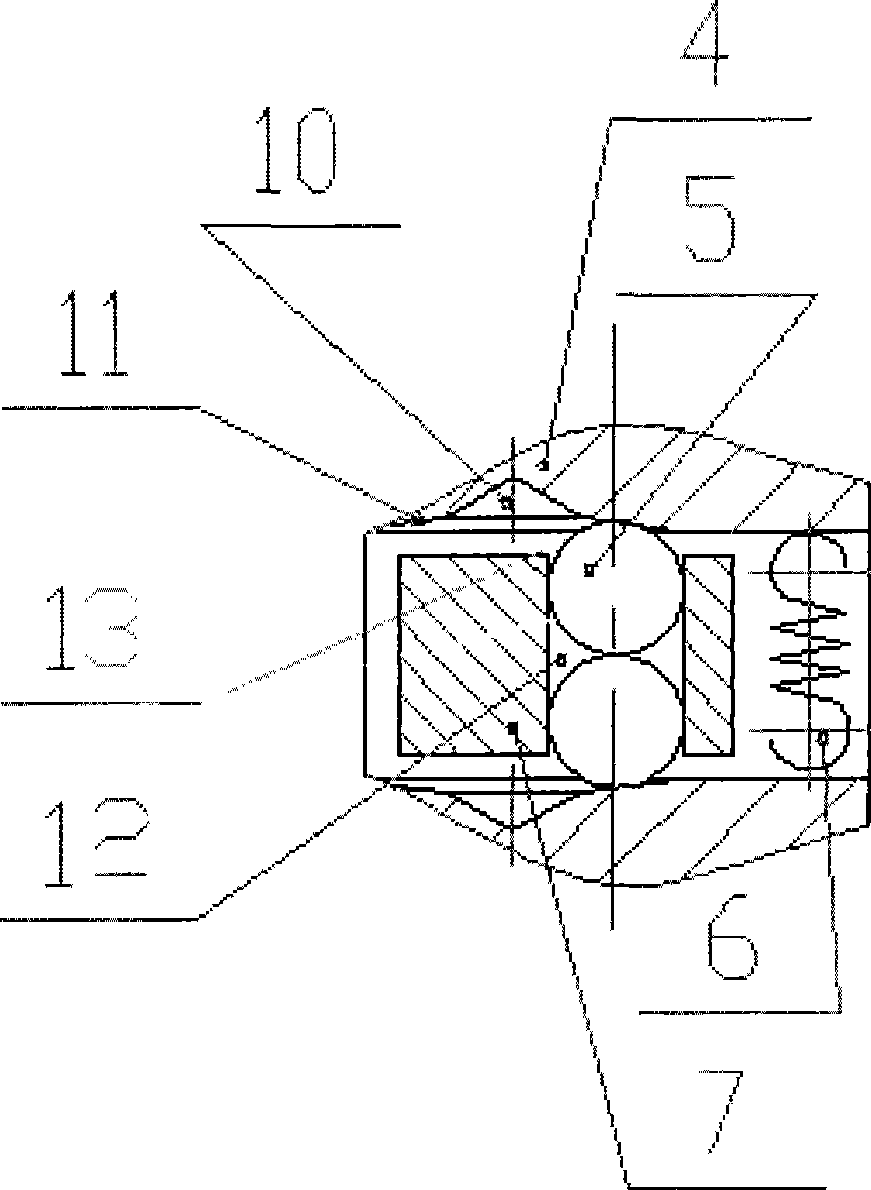

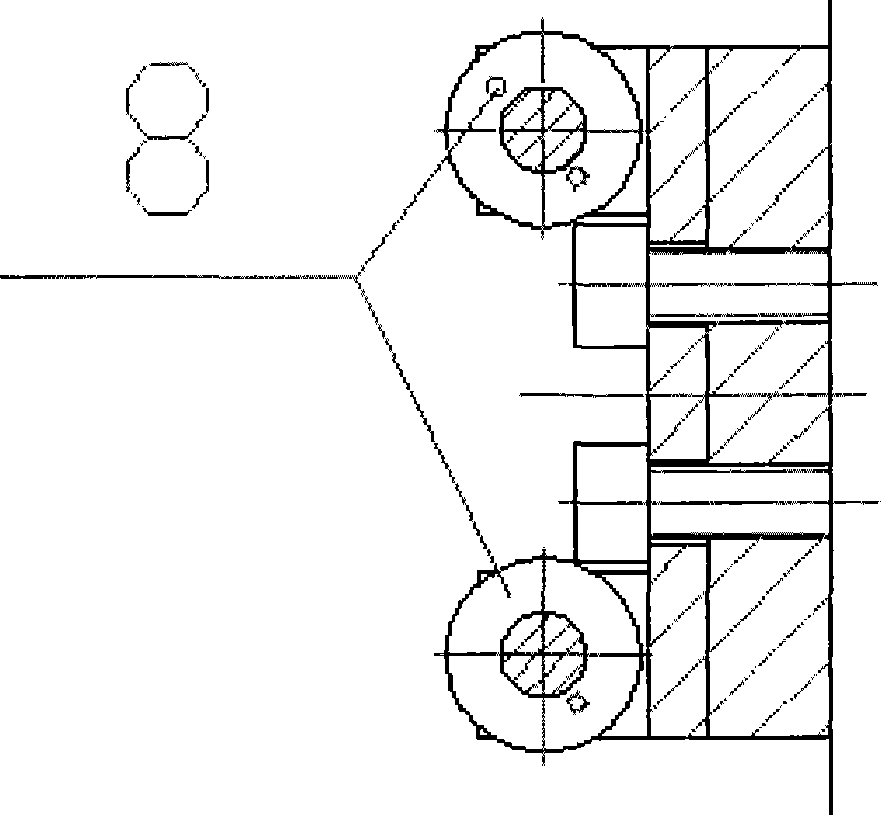

[0018] According to a preferred embodiment of the present invention, the double gate valve includes two valve devices, which are symmetrically arranged with respect to the valve stem 2, wherein each valve device includes a drive plate 7, a spring 6, a steel ball 5 , roller 9 and two valve plates 4. The valve plate 4 is floatingly supported on the driving plate 7 by the spring 6 and the steel ball 5 . Such as figure 2 As shown, a hole 12 is arranged in the drive plate 7, and two steel balls 5 are placed in the hole 12. The diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com