Method for feeding hydraulic fluid and coolant and lubricant for wet operation clutch of gear box

A hydraulic fluid, clutch technology, applied in the direction of clutch, friction clutch, mechanical drive clutch, etc., to achieve the effect of saving axial structure space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The mode of operation and the general construction of wet-running clutches or dual clutches are well known to those skilled in the art, so that the components relevant to the invention are described below.

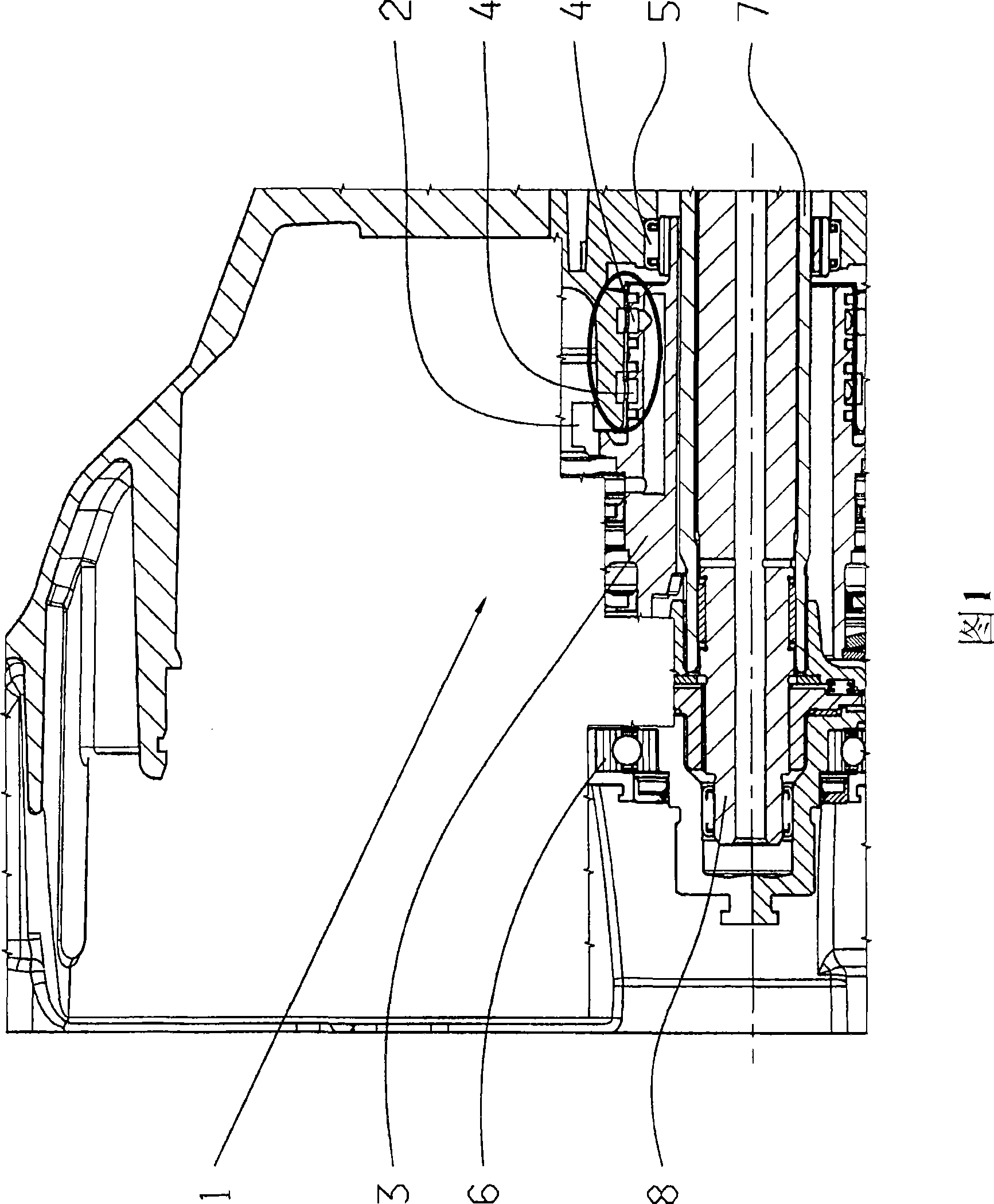

[0019] FIG. 1 shows a double clutch 1 comprising a pump transmission element designed as a pump transmission wheel 2 to which hydraulic fluid is supplied via a clutch sleeve 3 by means of a rotary converter 4 .

[0020] As can be seen from FIG. 1 , the bearing 5 for supporting the clutch is arranged axially behind the region in which the rotary converter 4 is arranged, thus disadvantageously increasing the axial construction space requirement. A further bearing 6 for supporting the clutch is arranged in front of the area in which the rotary converter 4 is accommodated, viewed in the axial direction. In addition, the outer drive shaft embodied as a hollow shaft is marked with 7 and the inner drive shaft guided by the hollow shaft 7 is marked with 8 , where each drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com