400kA energy-saving and emission-reducing pre-baked aluminum cell

An energy-saving and emission-reducing technology for aluminum electrolytic cells, applied in the field of 400kA prebaked aluminum electrolytic cells, can solve the problems of no significant improvement in the energy consumption and flue gas emission indicators of electrolytic cells, and reduce the amount of steel used, the difficulty of processing and production, and the current The distribution is even, and the effect of strengthening the bottom insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

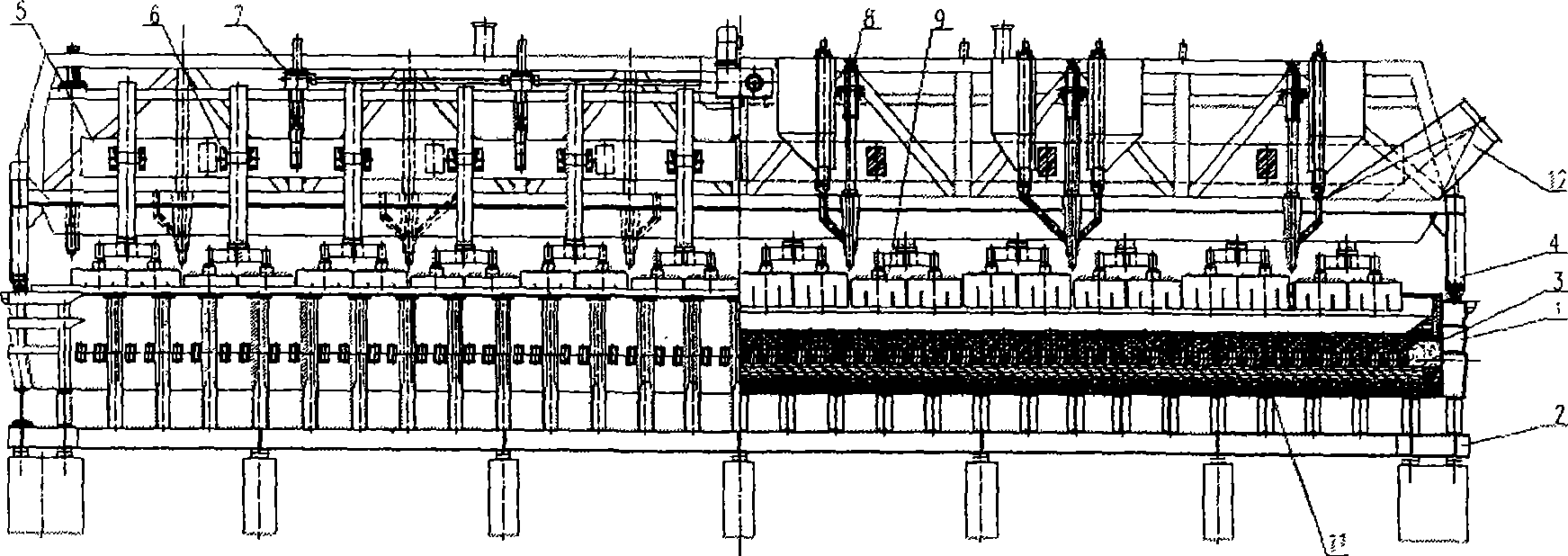

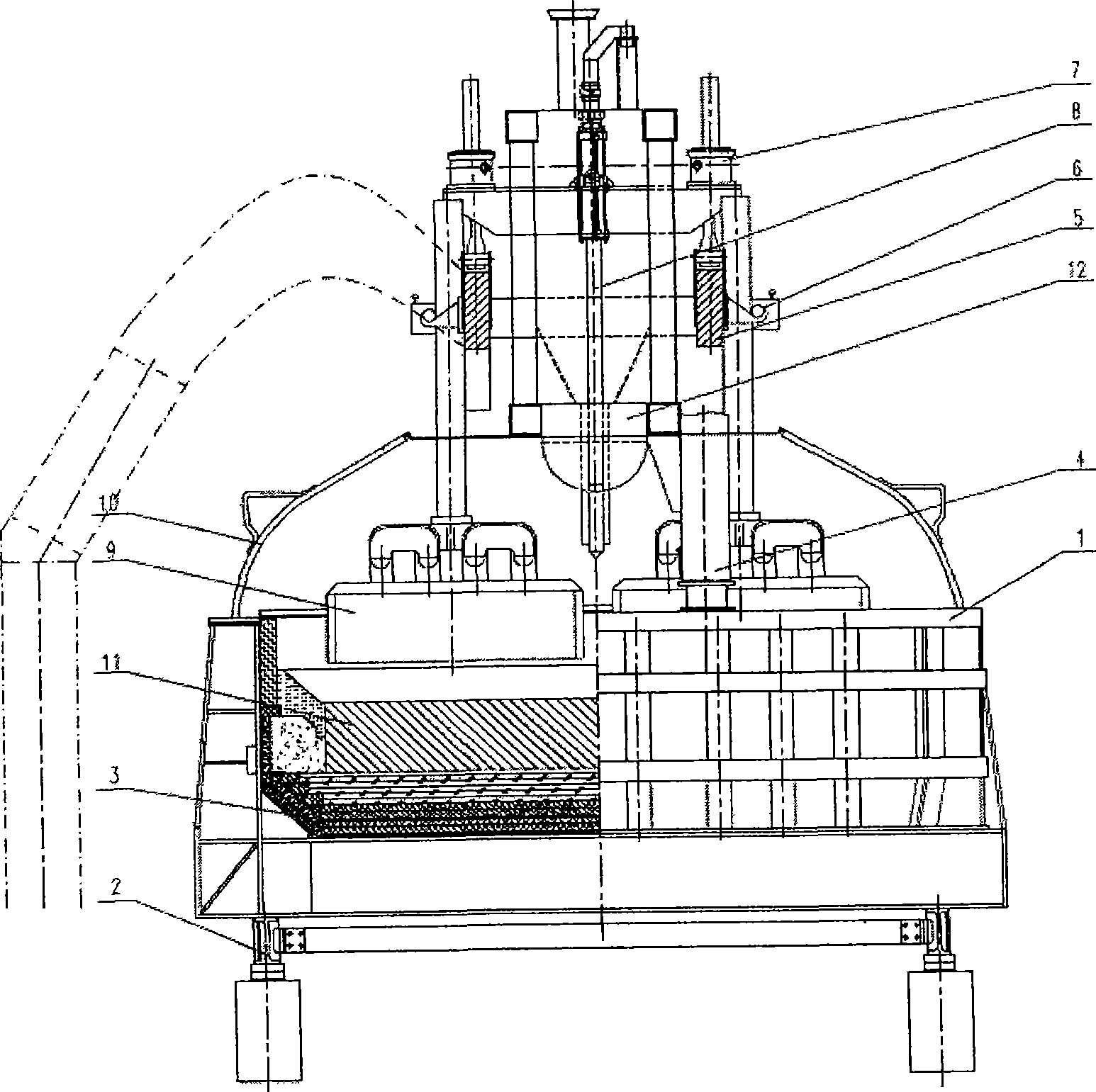

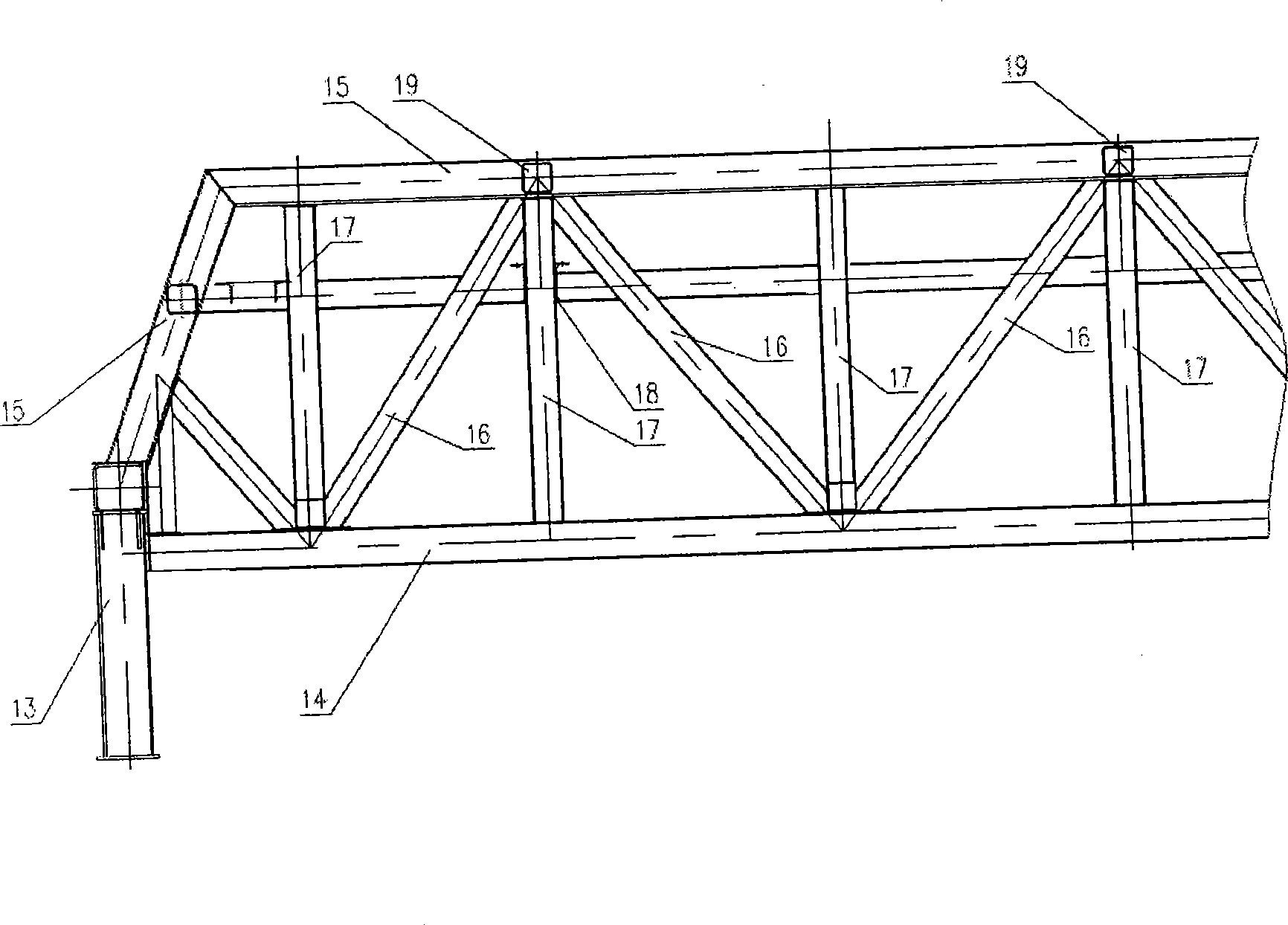

[0065] The structure of the 400kA energy-saving and emission-reducing prebaked aluminum electrolytic cell of the present invention will be further supplemented and explained below in conjunction with the accompanying drawings.

[0066] The upper structure of the prebaked aluminum electrolytic cell of the present invention includes an anode carbon block group 9, an anode bus bar 5, a shelling and unloading device 8, an anode lifting mechanism 7, a column girder 4 and a tank cover plate 10, a total flue 12, a flue The gas-gathering and exhausting system consists of zonal gas-collecting and exhausting pipes 32; the cathode structure includes the cathode carbon block group 11, the inner lining structure and the tank shell structure.

[0067] Such as figure 1 , 2 As shown, the following uses a 400kA electrolytic cell as an example to describe in detail. In fact, this design scheme can also be applied to a super-large prebaked aluminum electrolytic cell of 400kA to 550kA.

[0068]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com