Non feedback type AC frequency conversion apparatus for asynchronous motor

An asynchronous motor and AC frequency conversion technology, which is applied in the direction of AC motor control, conversion of AC power input to DC power output, and output power conversion devices, etc. power and other issues, to achieve the effect of reducing the cost and reducing the loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

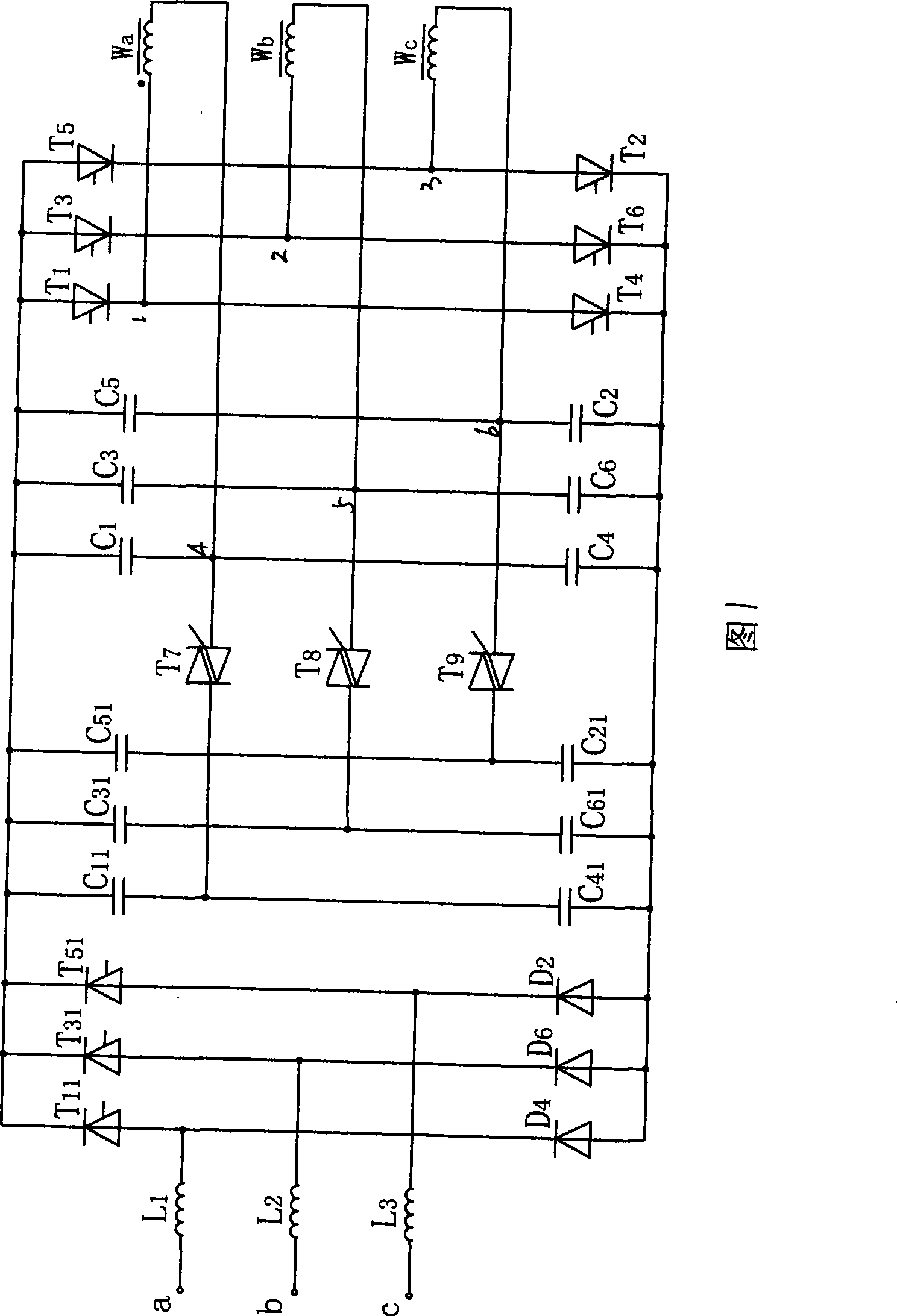

[0012] As shown in Figure 1, the non-feedback asynchronous motor AC frequency conversion device described in this embodiment is suitable for frequency conversion and speed regulation of ordinary asynchronous motors.

[0013]A non-feedback type asynchronous motor AC frequency conversion device, including a three-phase rectifier bridge (in this embodiment, a three-phase half-controlled rectifier bridge is composed of diodes D2, D4, D6 and thyristors T11, T31, T51, and L1 is connected in series at its three AC input terminals. , L2, L3 are three filter inductors connected to three power frequency power supply terminals, the DC terminal voltage can be adjusted in the range of 50% to 100% of the rated voltage, and a capacitor bridge is also used as a DC filter), connected to the three-phase rectifier A three-phase inverter bridge composed of six thyristors T1-T6 between the DC output terminals of the bridge, and three power capacitors C1, C4, C3, C6, and C5 are connected between the...

Embodiment 2

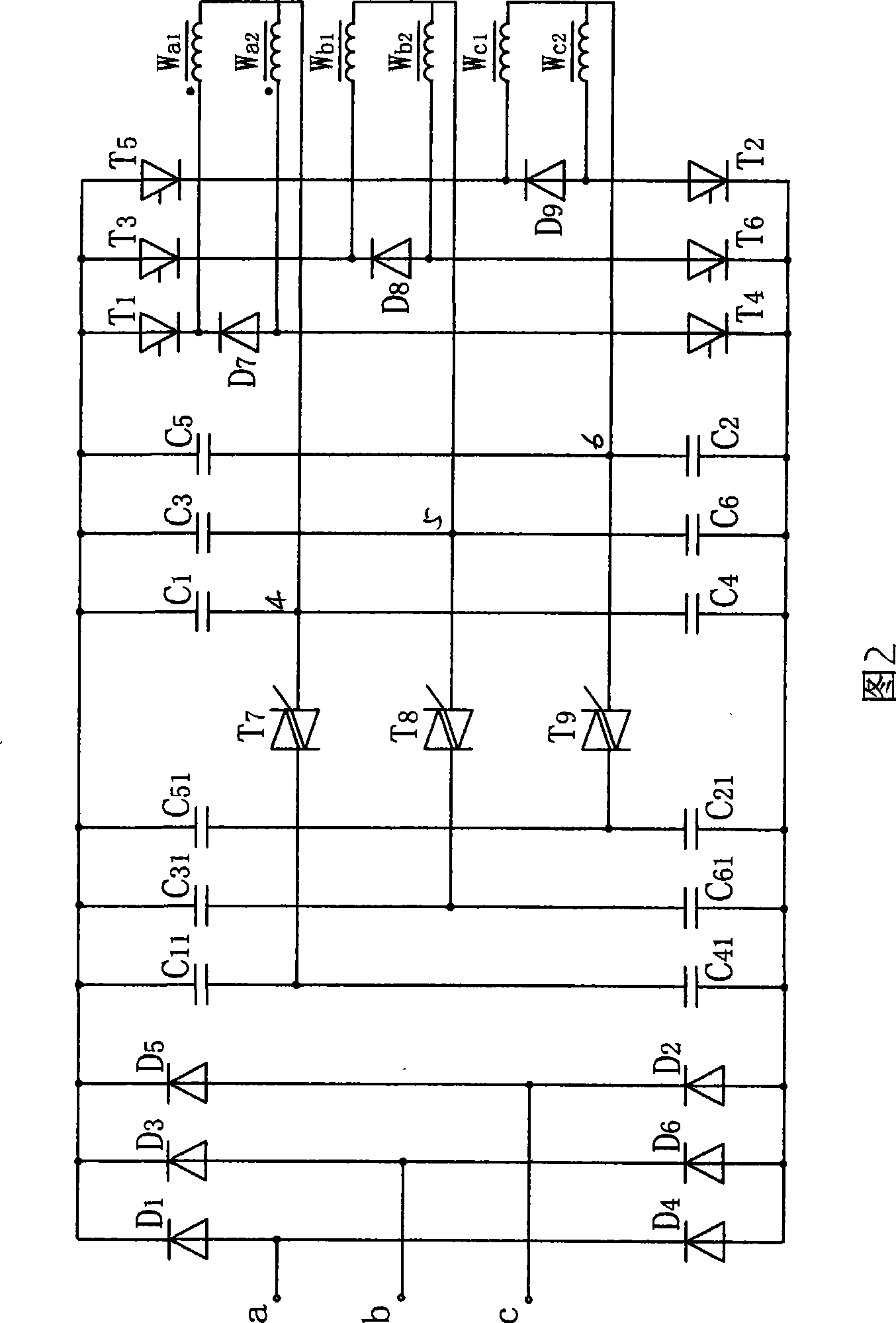

[0016] As shown in Fig. 2, the non-feedback asynchronous motor AC frequency conversion device described in this embodiment is suitable for frequency conversion and speed regulation of the "double-winding asynchronous motor" with the patent application number 2007101395855.

[0017] The non-feedback type asynchronous motor AC frequency conversion device includes a three-phase rectifier bridge (this embodiment is composed of diodes D1-D6, and its three input terminals are connected to three-phase power supply terminals a, b, and c), connected to three A three-phase inverter bridge composed of six thyristors T1-T6 between the DC output ends of the three-phase rectifier bridge, and three power capacitors C1, C4, C3, and C6 are connected between the DC output ends of the three-phase rectifier bridge. , C5, C2 connected in series to form the main capacitance bridge, the three midpoints 1, 2, and 3 of the three-phase inverter bridge lead out as one end of each phase of the three-phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com