Method for little air-gap generator motor assembling

A generator rotor and small air gap technology, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of not being able to adopt the wearing method, wearing the rotor, and not being able to use arc-shaped skateboards, etc., to achieve strong practicability , Reduce labor intensity and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

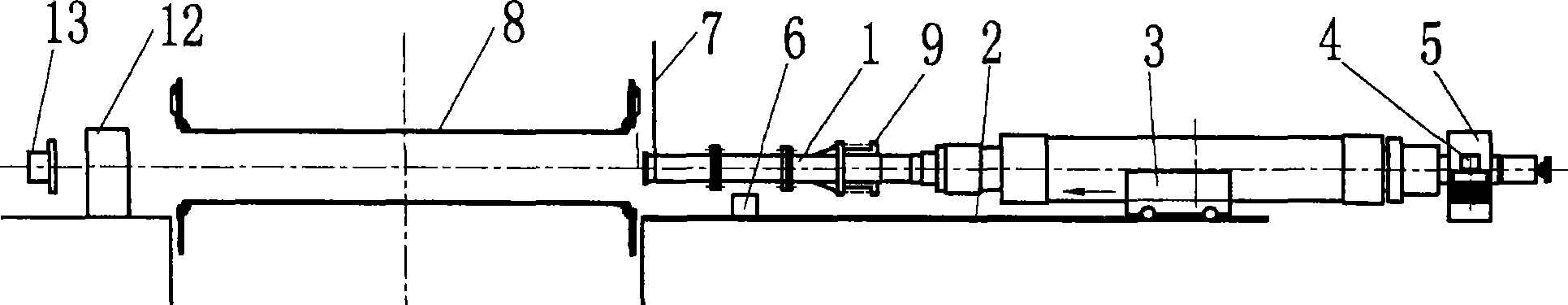

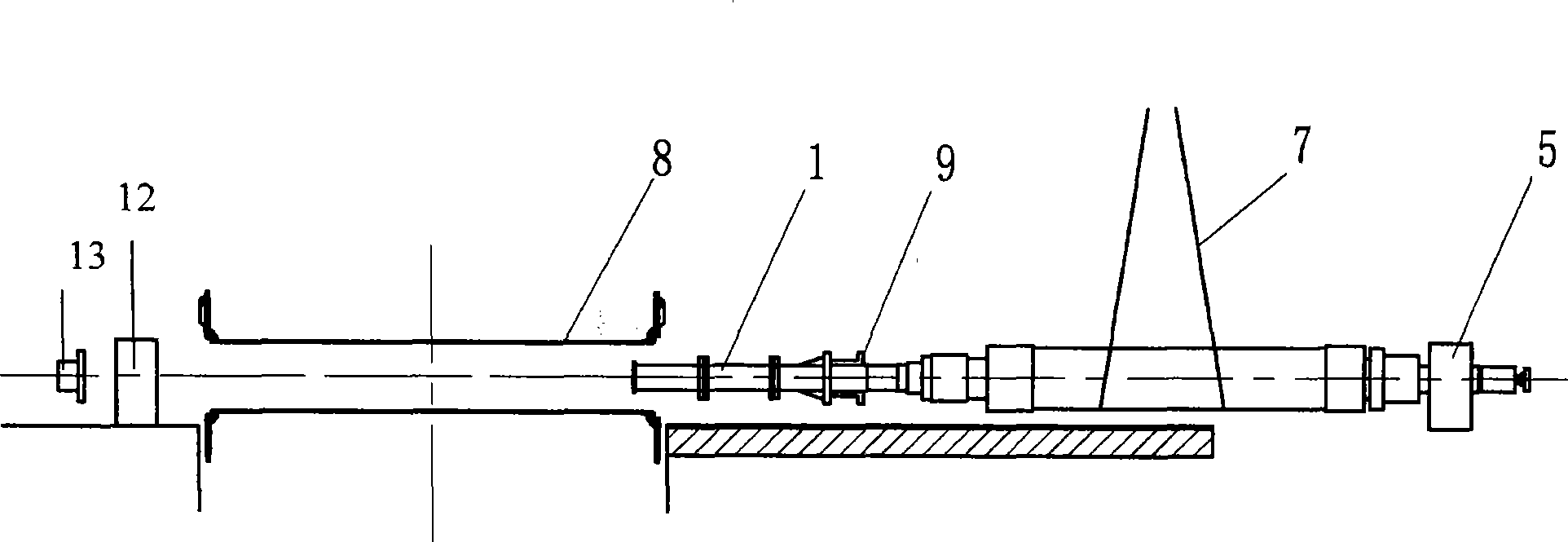

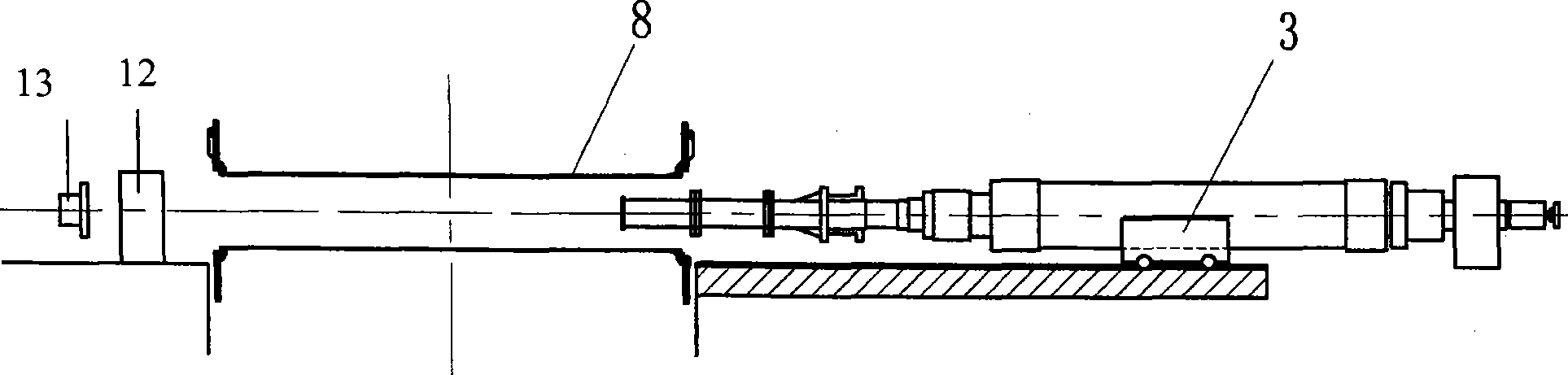

[0022] Such as figure 1 As shown in the figure, it is a schematic diagram of the tooling of the generator rotor. The tooling of the rotor of the generator consists of a connecting shaft 1, a guide rail 2, a trolley 3, a bracket 4, a excitation end bearing seat 5, a spacer 6, and a crane rope 7 , Sleeve 8, generator coupling 9, rotor bearing gear 10, rotor 11, steam end bearing block 12 and steam turbine coupling 13 are formed. The connecting shaft 1 is composed of at least three detachable short connecting shafts, which are connected to the rotor generator coupling 9 by bolts, and its function is to extend the rotor 11 so that when the rotor protrudes from the steam end, it can hang the connecting shaft. Shaft 1; trolley 3 can steadily carry rotor 11 and move forward slowly on guide rail 2; when trolley 3 drags rotor 11 at generator rotor bearing gear 10, bracket 4 should be used to cushion trolley 3, and hoop Firmly tie the rotor 11 on the trolley 3; the excitation end beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com