Optical interconnection device

A technology for optical interconnection and optical components, applied in optical components, optics, electrical solid-state devices, etc., can solve problems such as being unfavorable to mass production, reduce costs, etc., to improve optical coupling efficiency, increase installation tolerance, and reduce optical effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Now, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings.

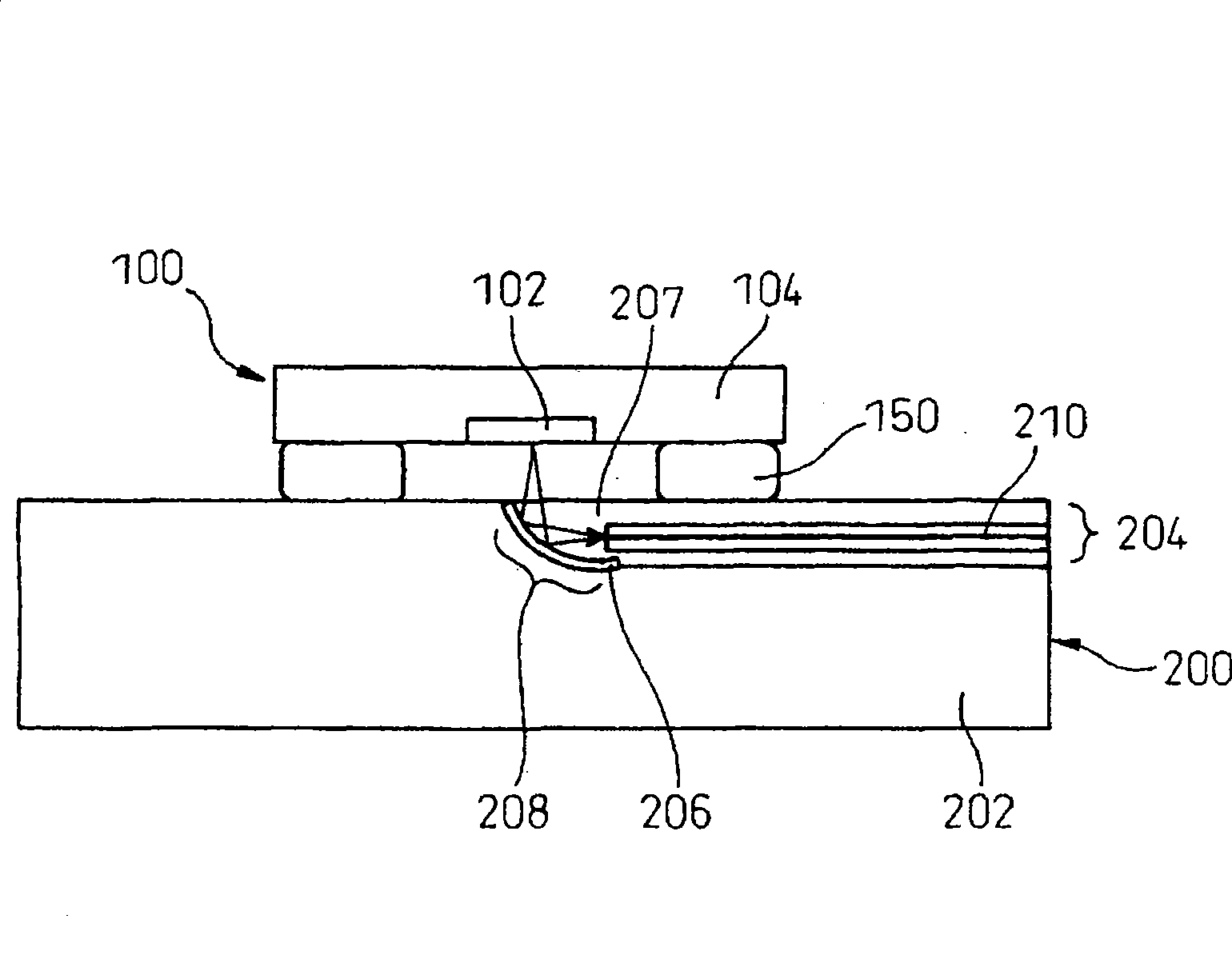

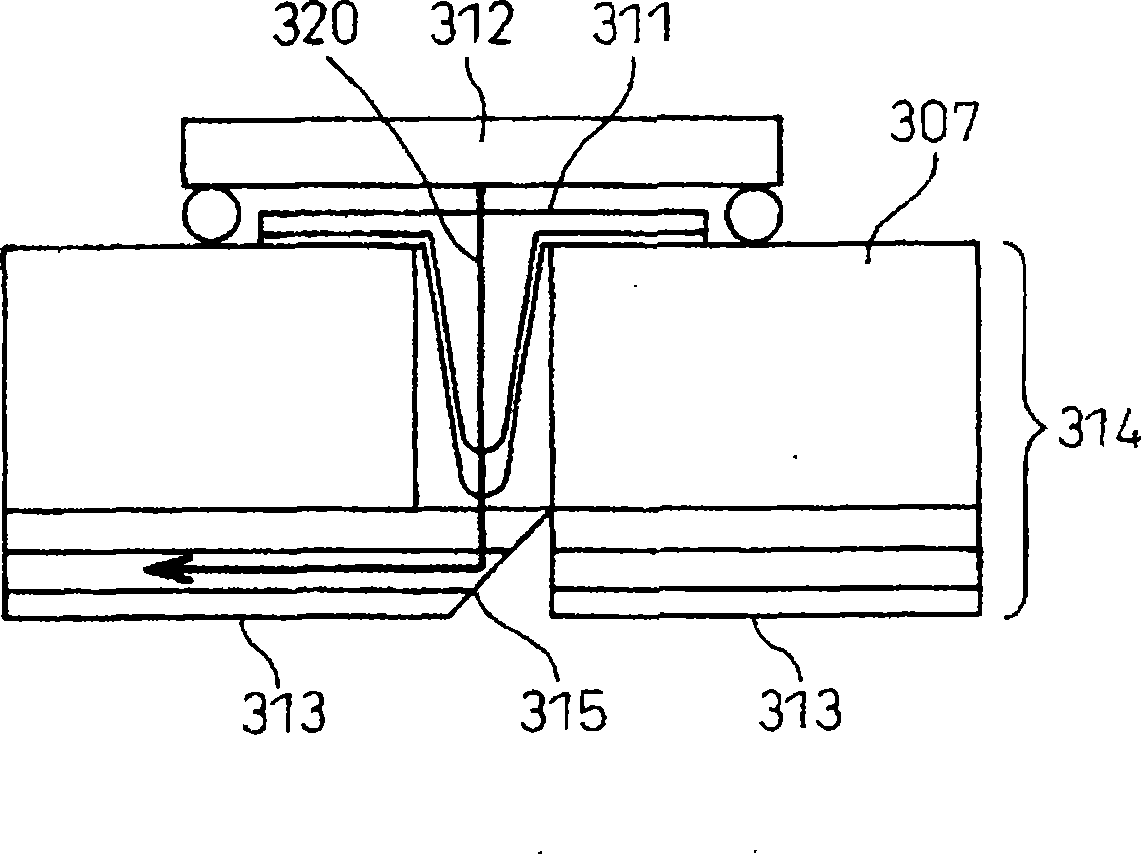

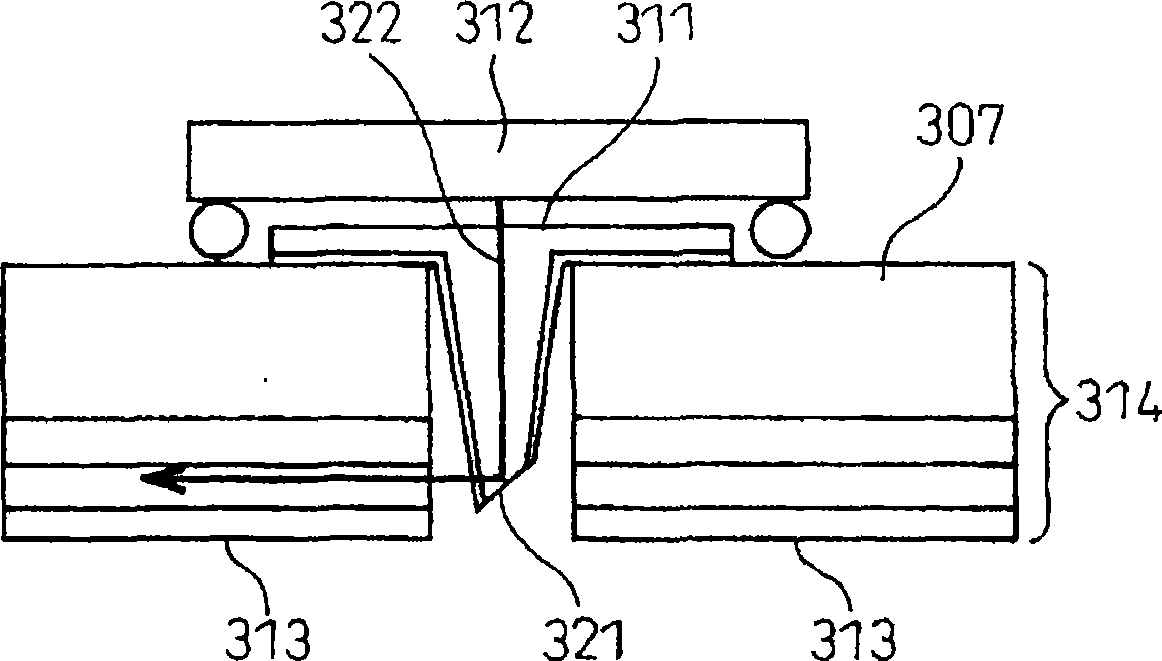

[0041] Figure 3 to Figure 8 A first exemplary embodiment of the present invention is shown. image 3 It is an optical interconnection device on which a substrate with a surface emitting element (hereinafter referred to as "surface emitting element substrate") is mounted. Figure 4 It is a cross-sectional view of an optical / electrical hybrid substrate on which a surface emitting element substrate is mounted. Figure 5 It is a cross-sectional view of an optical / electrical hybrid substrate on which no surface-emitting element substrate is mounted. Image 6 It is a plan view of an optical / electrical hybrid substrate on which no surface emitting element substrate is mounted. Figure 7 is a cross-sectional view of an optical waveguide substrate on which no surface-emitting device substrate is mounted. Figure 8 is a cross-sectional view of an opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com