Tube turning clamping and shrinking device

A shrinking device and clamping technology, applied in the direction of pipe supports, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of cumbersome procedures and high labor intensity, and achieve the effect of simple operation and shortening of bending time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

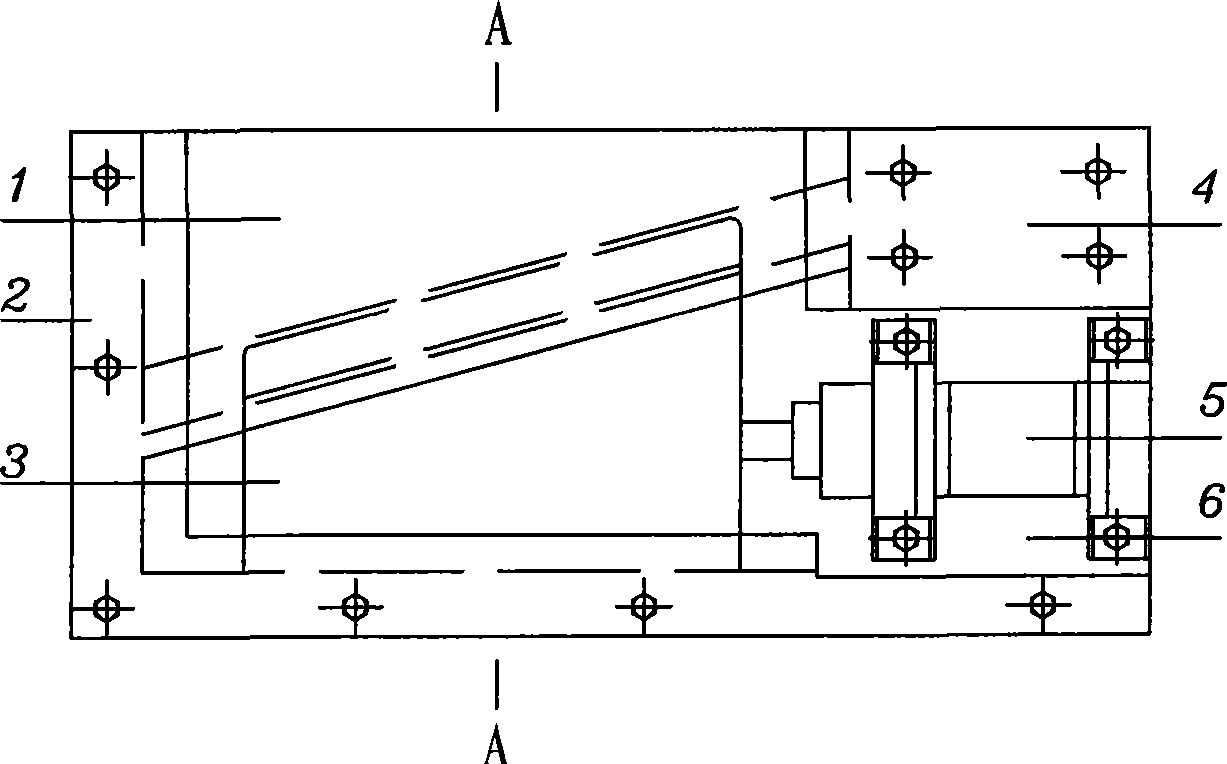

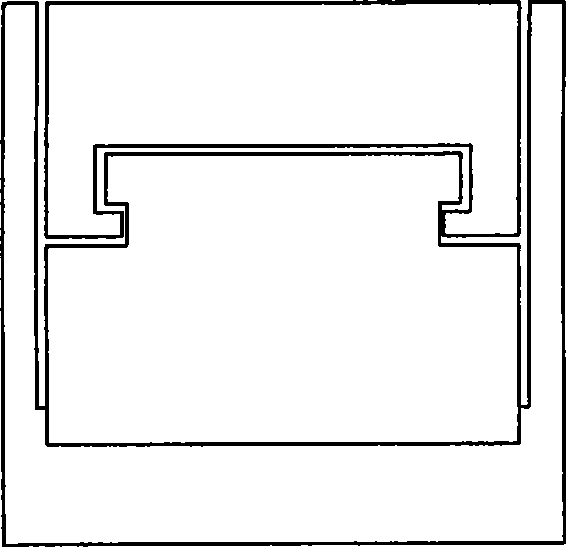

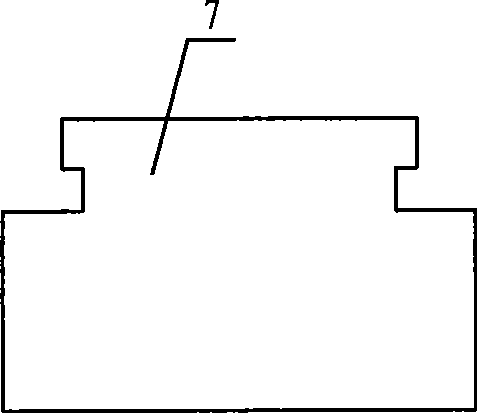

[0012] Such as figure 1 , 2 Shown: a pipe rotary clamping and shrinking device, the two sides of the translation wedge block 1 are completely contained in the guide grooves 2 and 4, so that the wedge block can only be translated in the direction of the slot under the action of external force sports. The main prominent point of this patent is that the embedded wedge-shaped block 3 is embedded in the wedge-shaped block 1, which is equivalent to that the wedge-shaped block 1 provides an embedded guiding sliding track for the wedge-shaped block 3. The upper and lower sides of the hydraulic cylinder 5 are respectively equipped with a lower cover plate, which is fixed on the lower cover plate 6 by screws. One end of the embedded wedge-shaped block 3 is fixed on the hydraulic cylinder 5, and the other end surface is contained in the guide groove 2, that is, The movement trajectory of the wedge-shaped block 3 is fixed, which is the same as that of the hydraulic cylinder 5. When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com