Mechanically-actuated folding trestle

A mechanically driven, folding technology, applied in construction and other directions, can solve the problems of slow erection and withdrawal, high labor intensity, difficult withdrawal and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

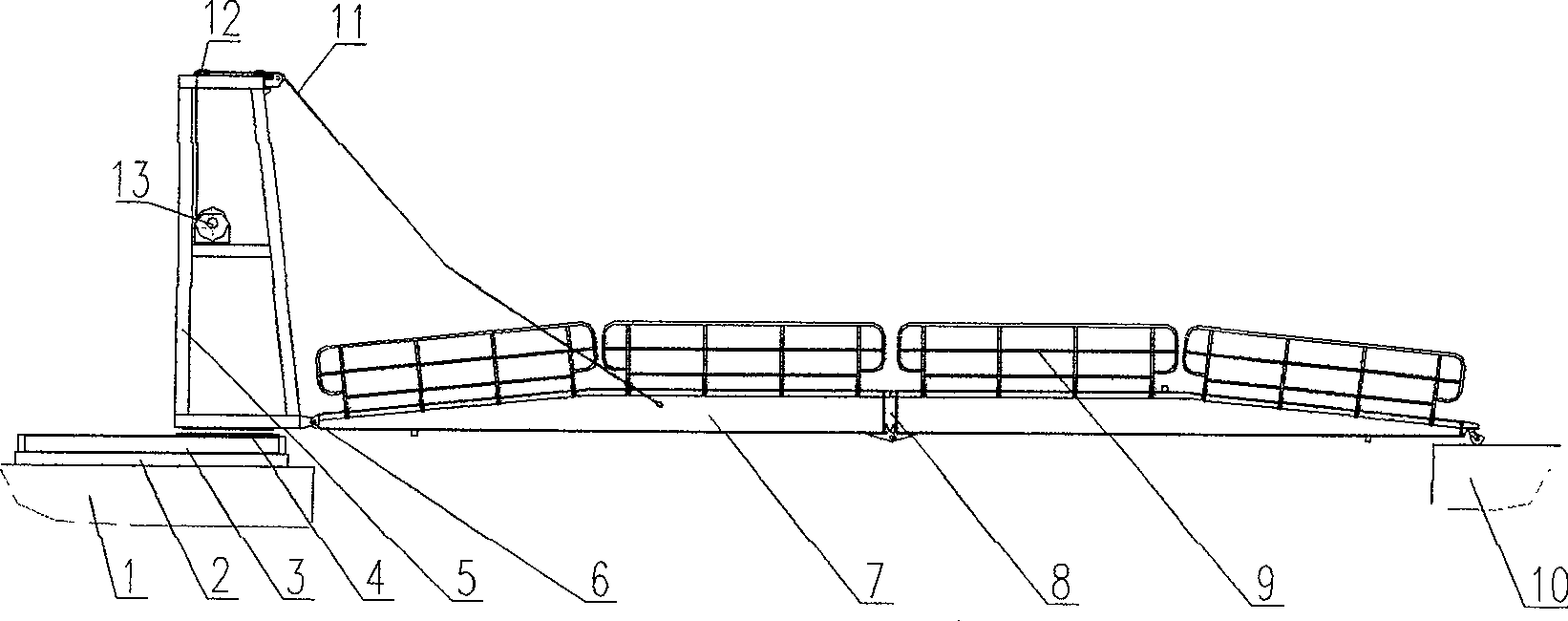

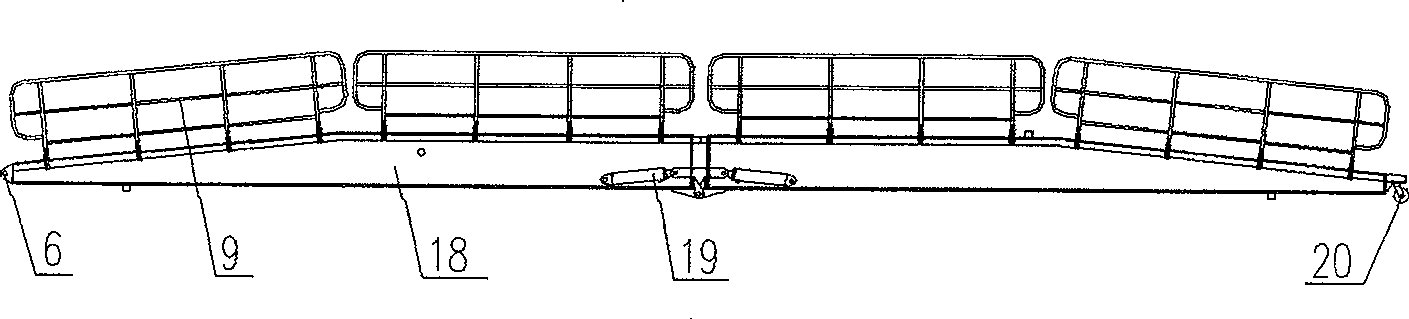

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

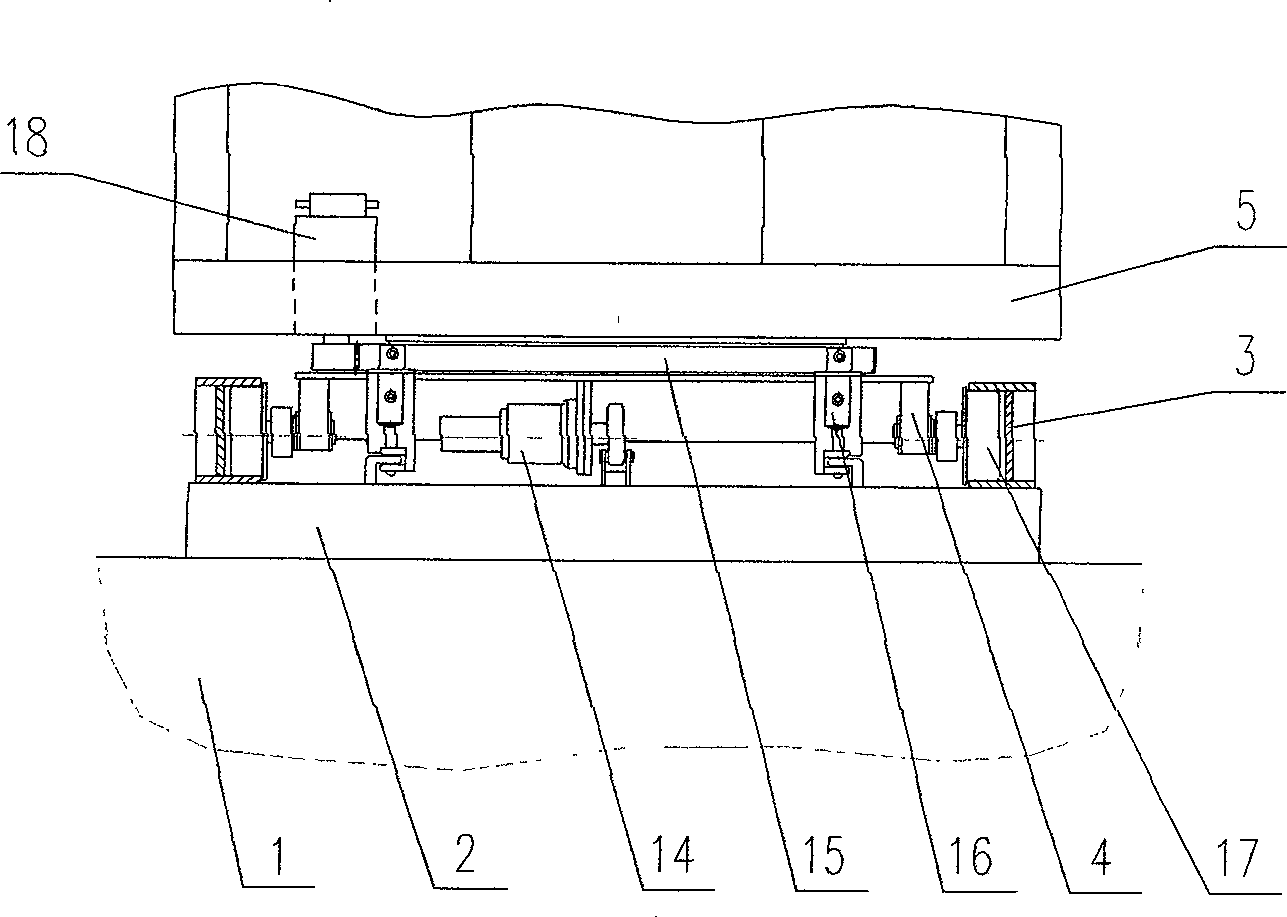

[0020] As shown in the drawings, the present invention is mainly composed of a base 2, a flat car 4, a running mechanism 14, a door-shaped support 5, a slewing mechanism 18, a winch 13, a bridge span 7, a hydraulic system, an electrical system, etc., wherein the hydraulic system , The electrical system constitutes the trestle control system. The connections and functions of each part of the entire trestle bridge are:

[0021] The base 2 is directly fixed on the deck of the offshore fixed platform 1 . A slideway 3 is provided on the base 2 , and a roller 17 is provided on the flat car 4 , which can move back and forth in a straight line in the slideway 3 through the driving of the traveling mechanism 14 arranged between the base 2 and the flat car 4 . During operation, the flat car 4 and the components on it can be moved to the required overlapping position accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com