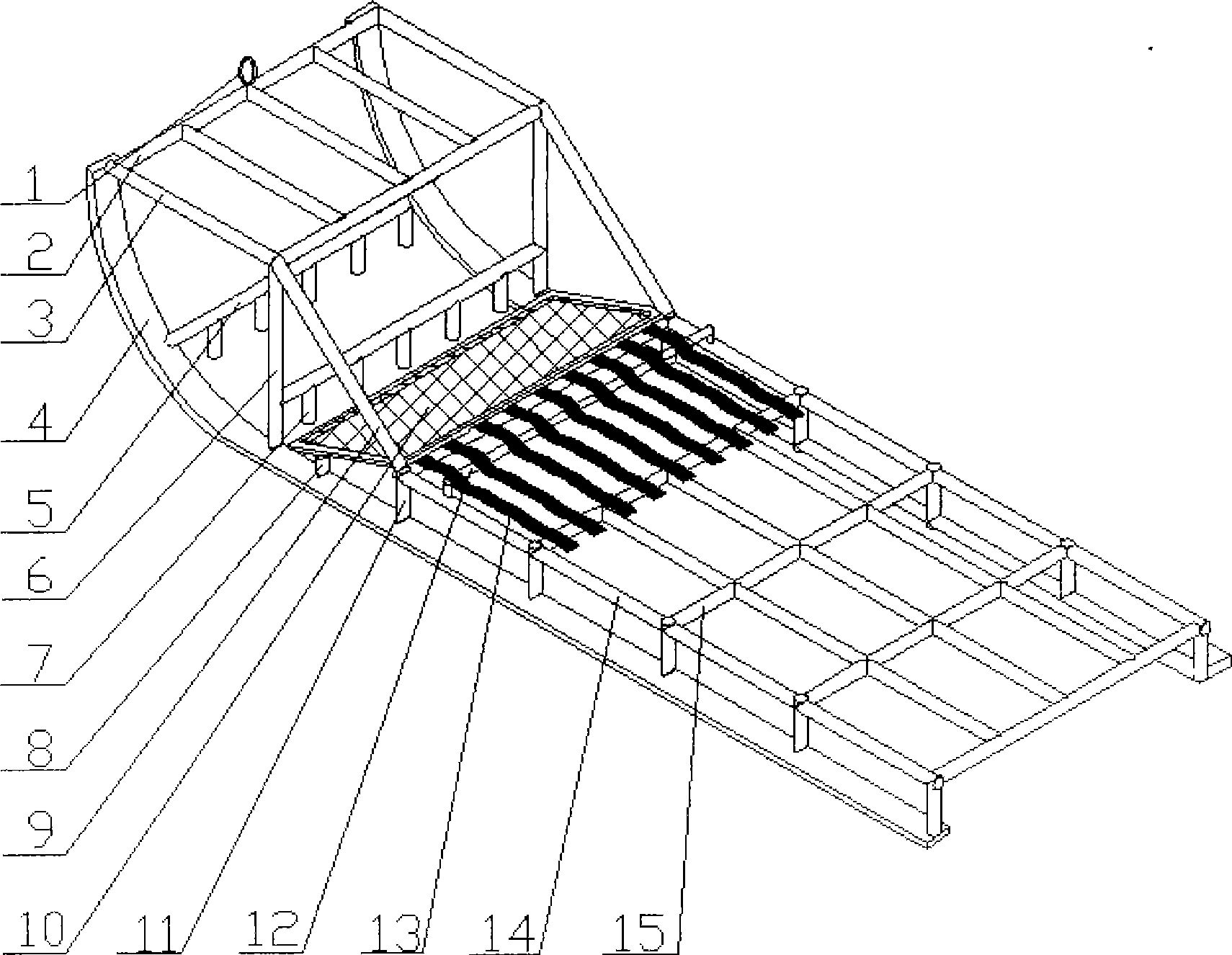

Scallop catching net

A technology for nets and scallops, applied in the field of mechanical devices, can solve the problems of large resistance, large friction, and high energy consumption of the sling, and achieve the effects of easy manufacture and operation, low energy consumption, and high fishing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The main body of the present invention is two stainless steel plates 4 with a radian at one end, and the horizontal part of the stainless steel plate 4 is respectively welded with five evenly distributed short struts B11, a short strut A8 and a long strut 6 to the arc direction, and two long struts Between the other ends of the 6 and between the tops of the 4 arcs of the stainless steel plate, there is respectively welded a mesh head bar 2, five short tie rods 3 are welded on average between the two mesh head bars 2, and between the tops of the 4 arcs of the stainless steel plate Welding ring 1 on the net head cross bar 2, two long pillars 6 are connected to one end of the net head cross bar 2 by two diagonal stay rods 9 to the two short pillars B11 closest to it, five pairs of short pillars B11 are welded There are five trawl frame cross bars 15, and five tie rods 14 are evenly distributed on the trawl frame cross bar 15, and two auxiliary cross bars 5 are welded at the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com