Method for producing a multilayered part

A multi-layer, component technology, applied in the direction of thin material handling, transportation and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

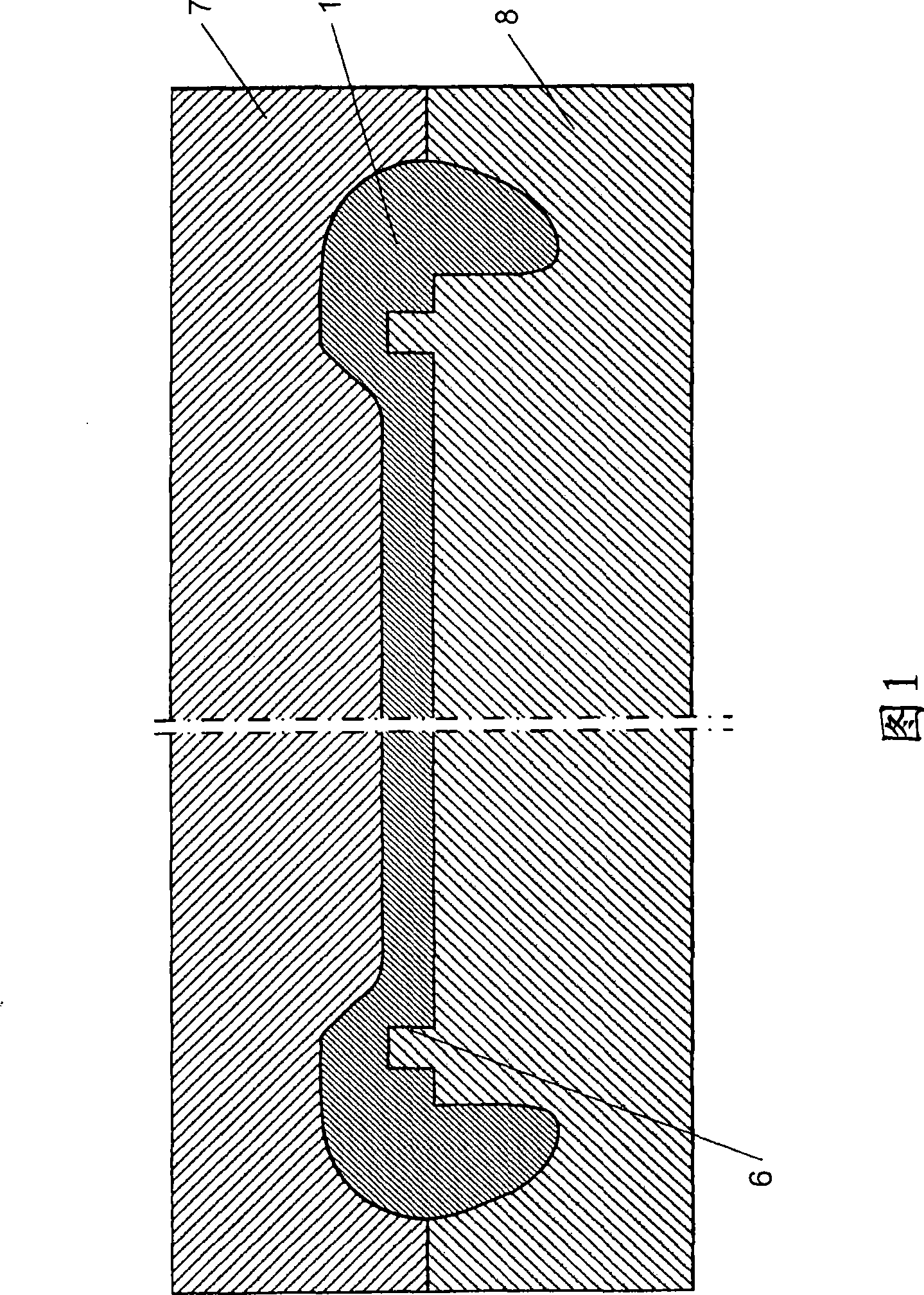

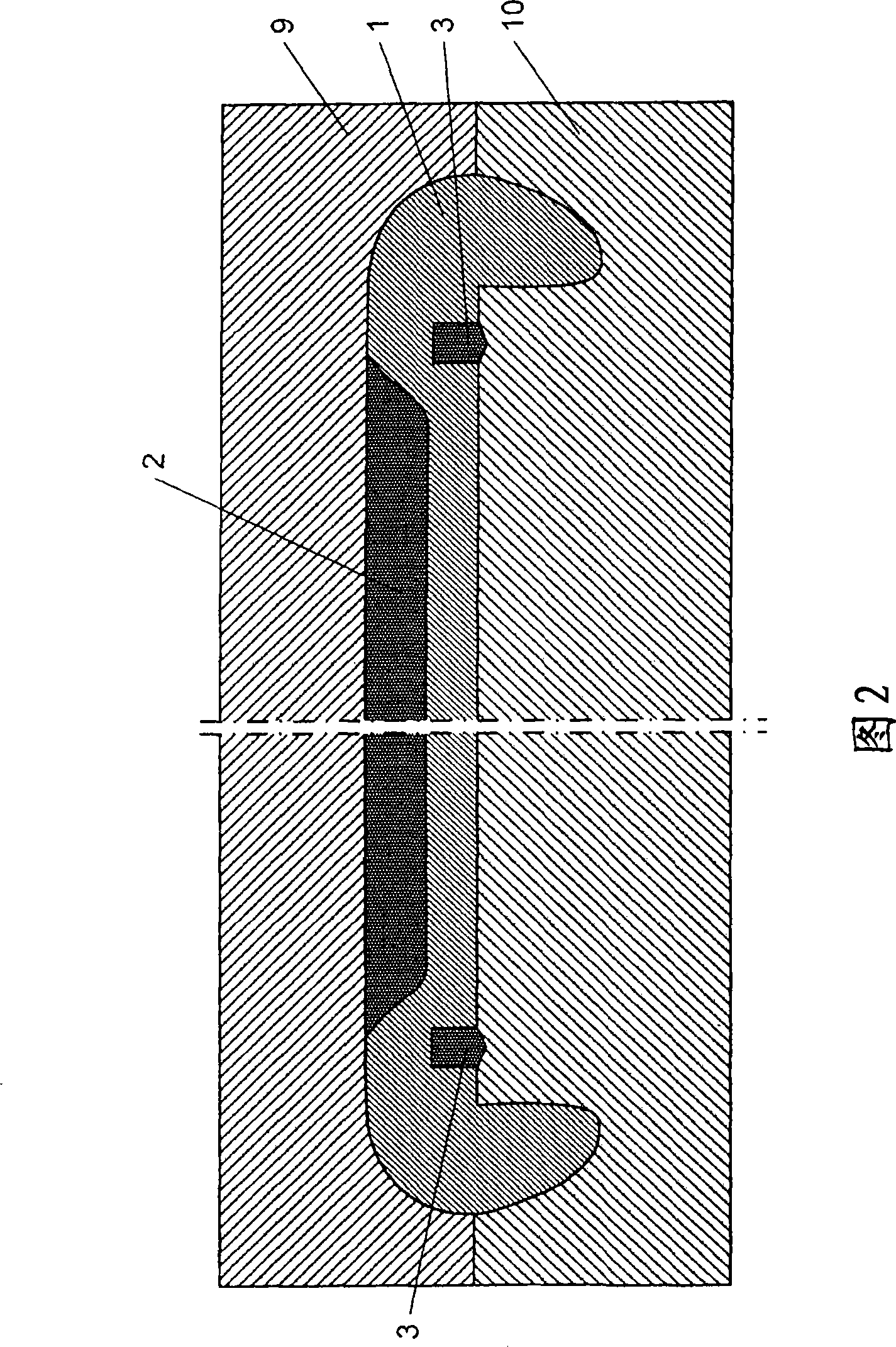

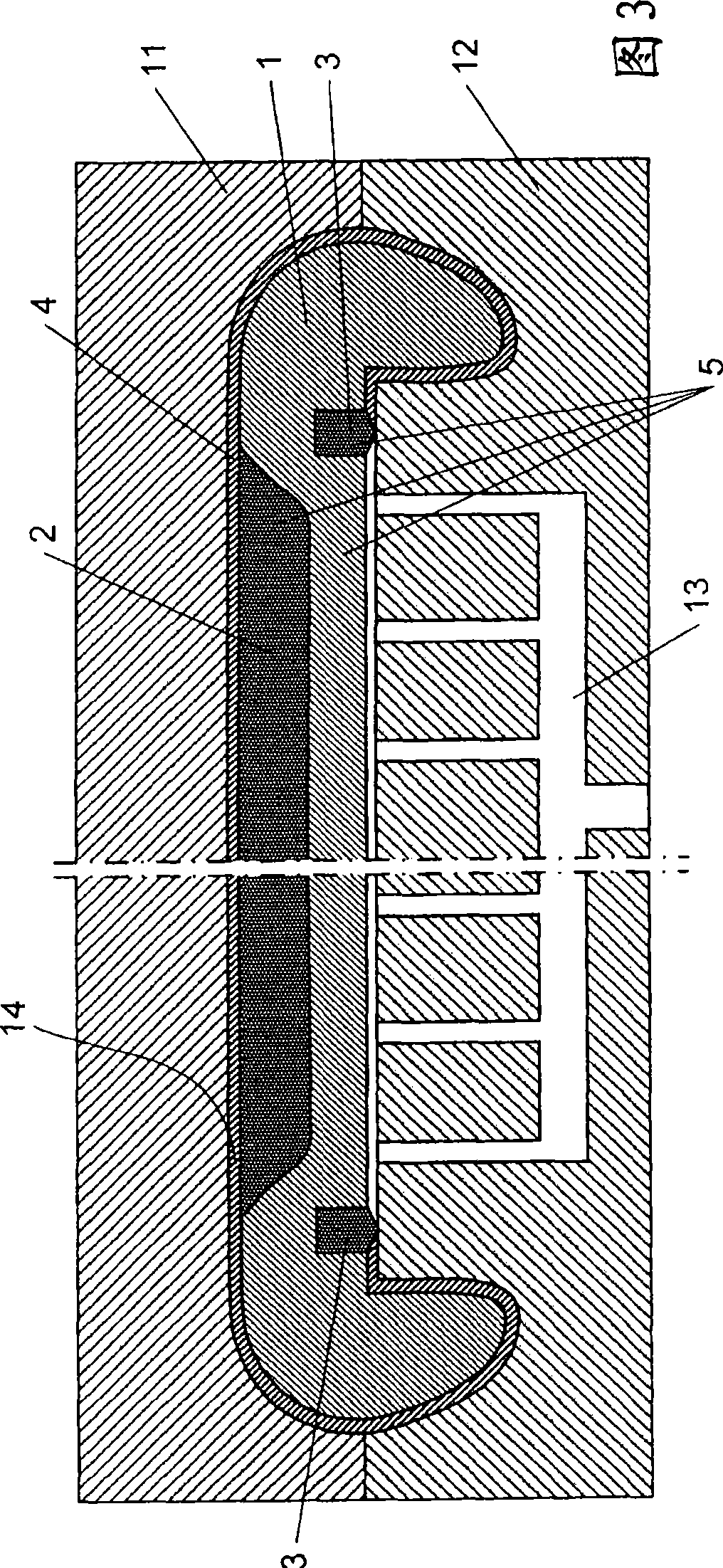

Image

Examples

example 1

[0042] The PC / ABS base layer was molded by injection molding in the form of a 20 cm x 20 cm panel. One side of this board was overmolded with a layer of SEBS of 6mm thickness. The SEBS layer has about 1000kg / m 3 Density and Shore A hardness of 0. The SEBS layer is then overmolded with a polyurethane reaction mixture to produce a 3 Density polyurethane skin.

[0043] In order to measure the additional softness obtained by the SEBS layer, the ILD (Indentation Load Deflection) value of the multi-layered part was determined, which refers to the need for a 14mm stamping head to punch 2mm of the material at a speed of 5mm / min. force. The same ILD value determination was carried out on a commonly used multilayer part, which included a PC / ABS base layer, a commonly used semi-flexible polyurethane back foam layer (with a thickness of 15mm) and also with a 1.2mm The same polyurethane surface layer of average thickness. The ILD value of the multilayer ROM part measured by the method ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com