Plug with separating mechanism of unlocking sleeve

A separation mechanism and unlocking sleeve technology, which is applied to the parts, electrical components, coupling devices and other directions of the connecting device, can solve the problem of inability to unlock and separate the rod head seat, achieve convenient maintenance, simplify the projectile structure, and narrow the operating space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

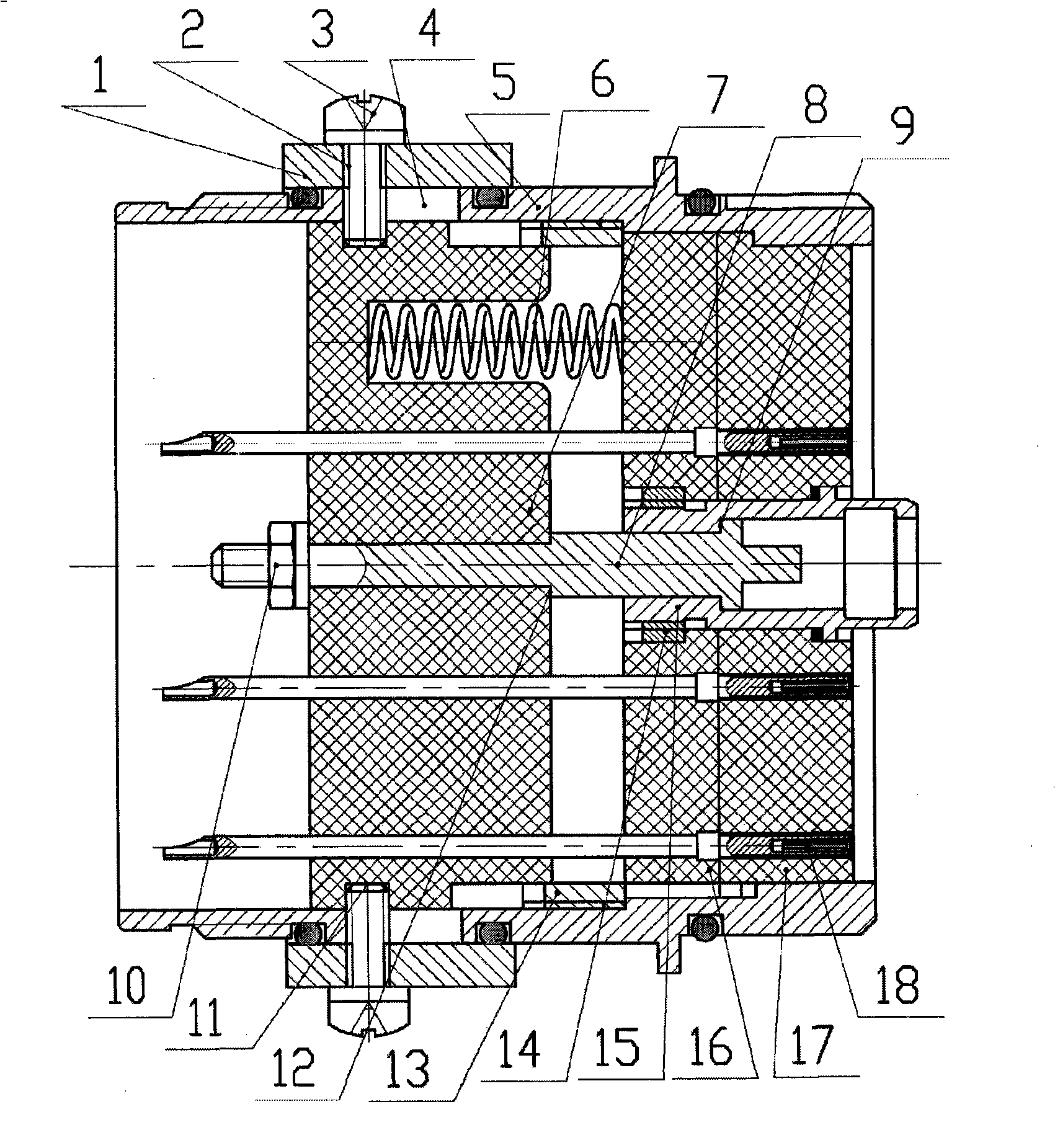

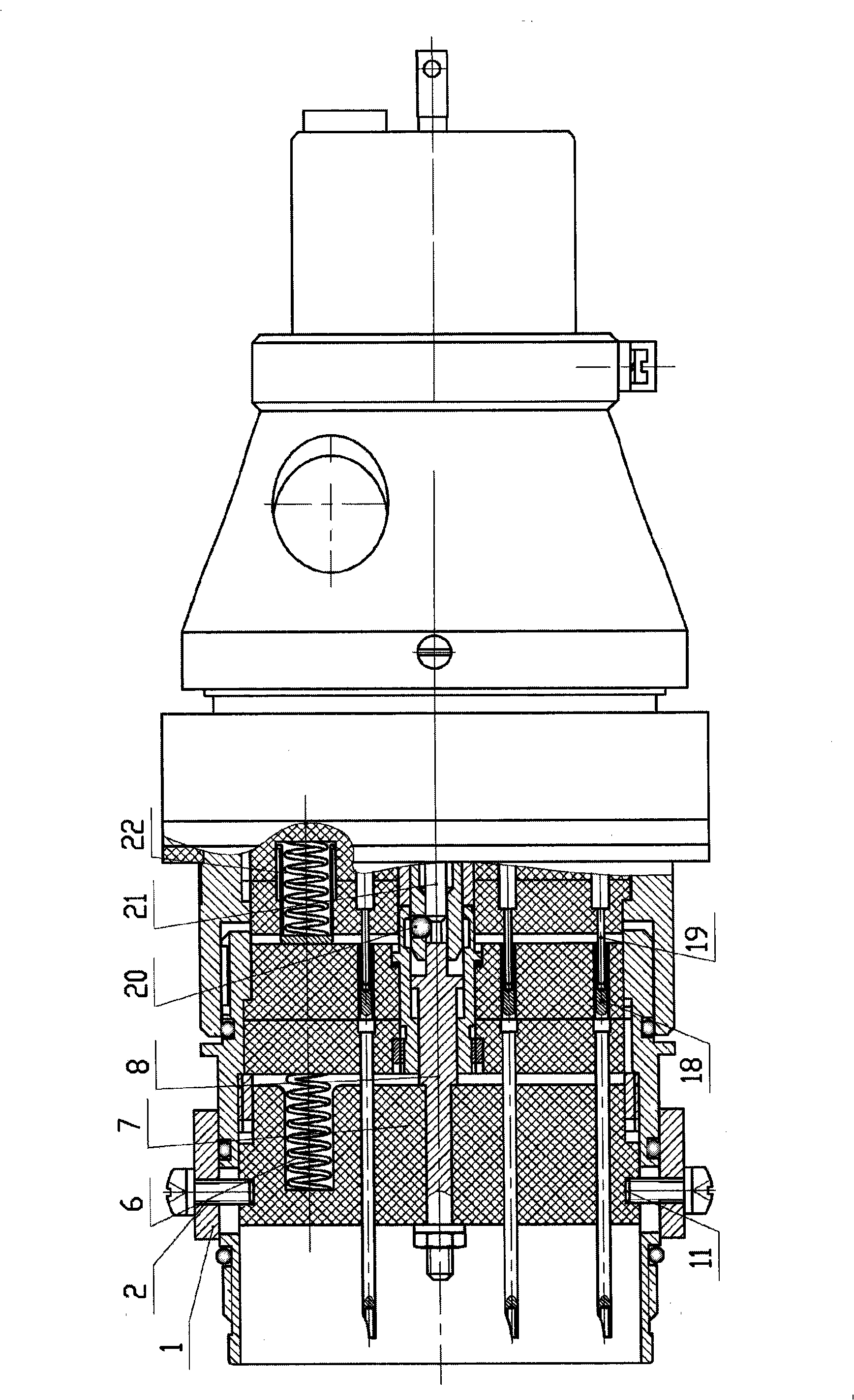

[0011] Such as figure 1 As shown, the unlocking sleeve separation mechanism is provided with an unlocking sleeve 1, and the unlocking sleeve is provided with 4 threaded holes 2, and the threaded holes 2 cooperate with 4 screws 3. There is a waist-shaped groove 4 on the shell 5, and the screw can move in the waist-shaped groove 4. After the screw is installed in place, the unlocking sleeve can be restricted on the housing and will not come out of the connector.

[0012] After the screw 3 is installed, it passes through the four waist-shaped grooves 4 on the housing 5 and enters the four counterbores 11 provided on the movable insulating plate 7 . After the screw 3 is installed in place, it can move with the unlocking sleeve 1 in the groove 4 on the housing 5, and drive the movable insulating plate 7 to move together. There is a through hole in the center of the movable insulating plate 7, and the ejector rod 8 passes through the through hole, and is fixed on the movable insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com