Wind generator system

A technology for wind power generation systems and generators, applied in wind power generator components, wind power generation, wind power engines, etc., can solve the problems of high wind energy utilization rate, excessive blade diameter, difficult cost, etc., and achieve high wind energy utilization rate and low cost The effect of reducing the wind area and facilitating transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

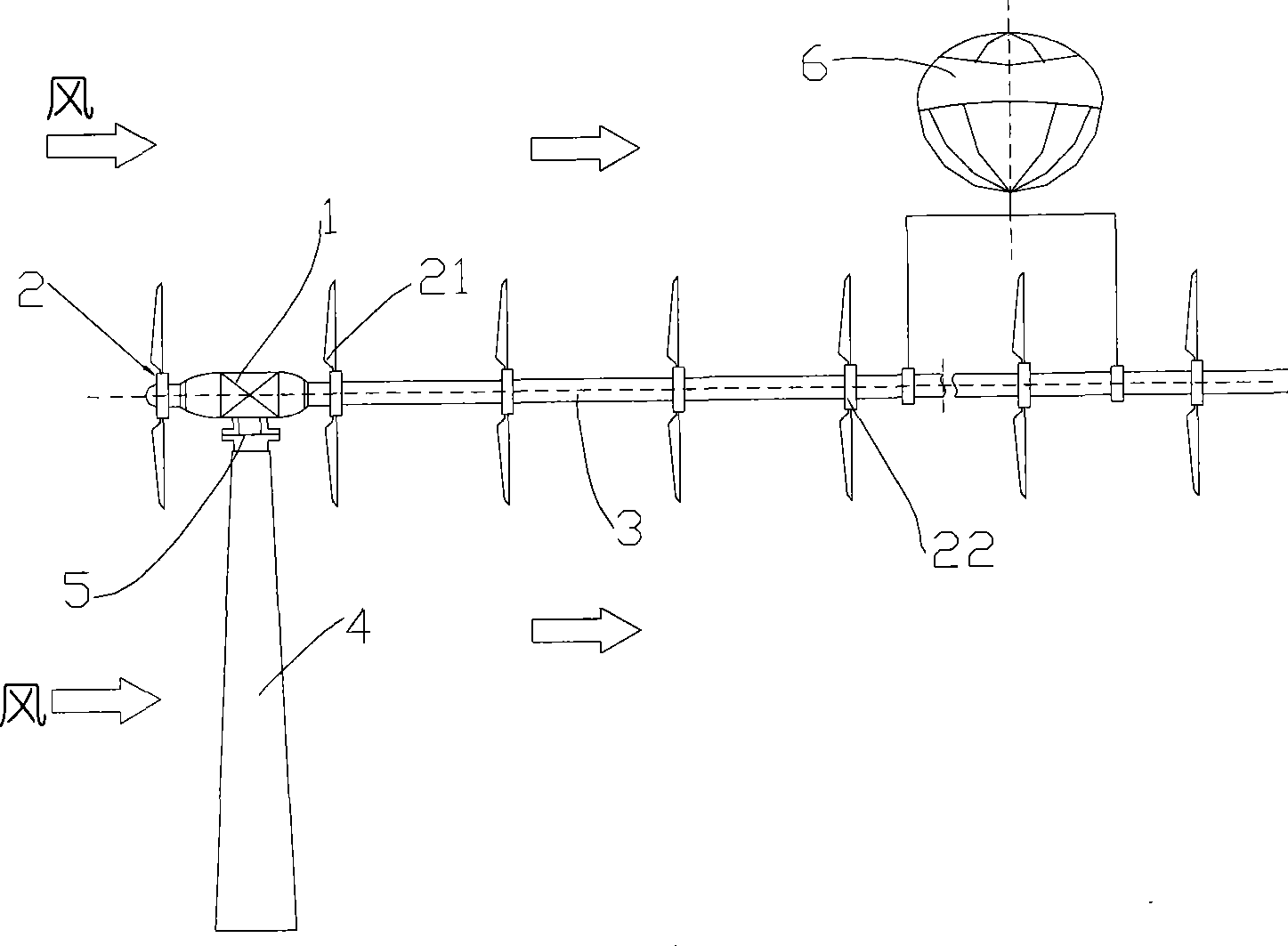

[0033] see figure 1 , figure 2As shown, a wind power generation system includes a tower 4, a generator assembly 1 arranged on the tower 4, and a transmission shaft 3 connected to the generator assembly 1, and the movement along the axial direction of the transmission shaft 3 is kept at intervals. A multistage wind wheel 2 is installed. The generator assembly 1 is installed on the tower 4 through the direction adjustment device 5, so that the axial direction of the transmission shaft 3 can be adjusted according to the wind direction, so that the rotating surface of the wind wheel 2 faces the flow direction of the wind at any time.

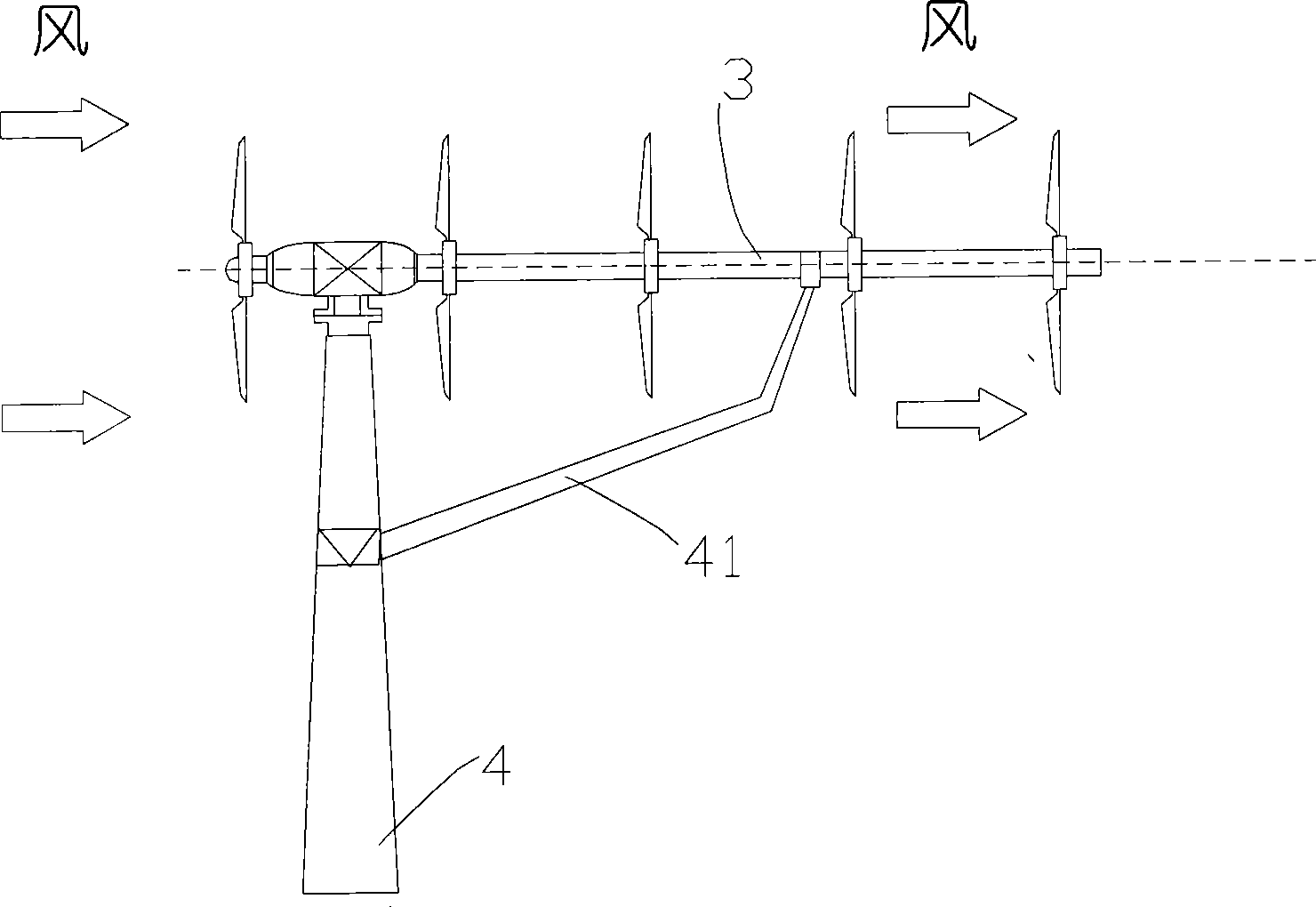

[0034] When the transmission shaft 3 is longer and the number of stages of the wind wheel 2 is more, the tail end of the transmission shaft 3 can be equipped with a balloon floating system 6 . see image 3 As shown, when the transmission shaft 3 is shorter and the number of stages of the wind wheel 2 is less, a support bracket 41 can be provided...

Embodiment 2

[0045] see Figure 9 As shown, the difference from the first embodiment is that the elastic coupling mechanism 24 of this embodiment is arranged outside the transmission shaft section 35, which includes a fixed plate 36, a tension spring or a compression spring 241 arranged on the corresponding transmission shaft section 35, One end of the tension spring or compression spring 241 is connected to the fixing plate 36 , and the other end is connected to the hub 22 of the wind wheel 2 on the transmission shaft section 35 .

Embodiment 3

[0047] see Figure 12 As shown, different from the above-mentioned embodiments, this embodiment does not use the elastic coupling mechanism 24, but sets the shaft tube sheath 34 as a bellows with telescopic elasticity, and the two ends of the shaft tube sheath 34 are respectively connected to the corresponding The hub 22 of the adjacent wind wheel 2 is connected. At this time, the shaft tube sheath can not only protect the transmission shaft, but also elastically constrain the adjacent wind rotors, so that the adjacent wind rotors will not collide with each other due to the blowing of the wind, which further simplifies the structure of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com