Motion mechanical energy storage and release device

A technology for releasing devices and mechanical energy, which is applied in the direction of engines, mechanical equipment, elastic motors, etc., to achieve the effect of energy reduction and extensive economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

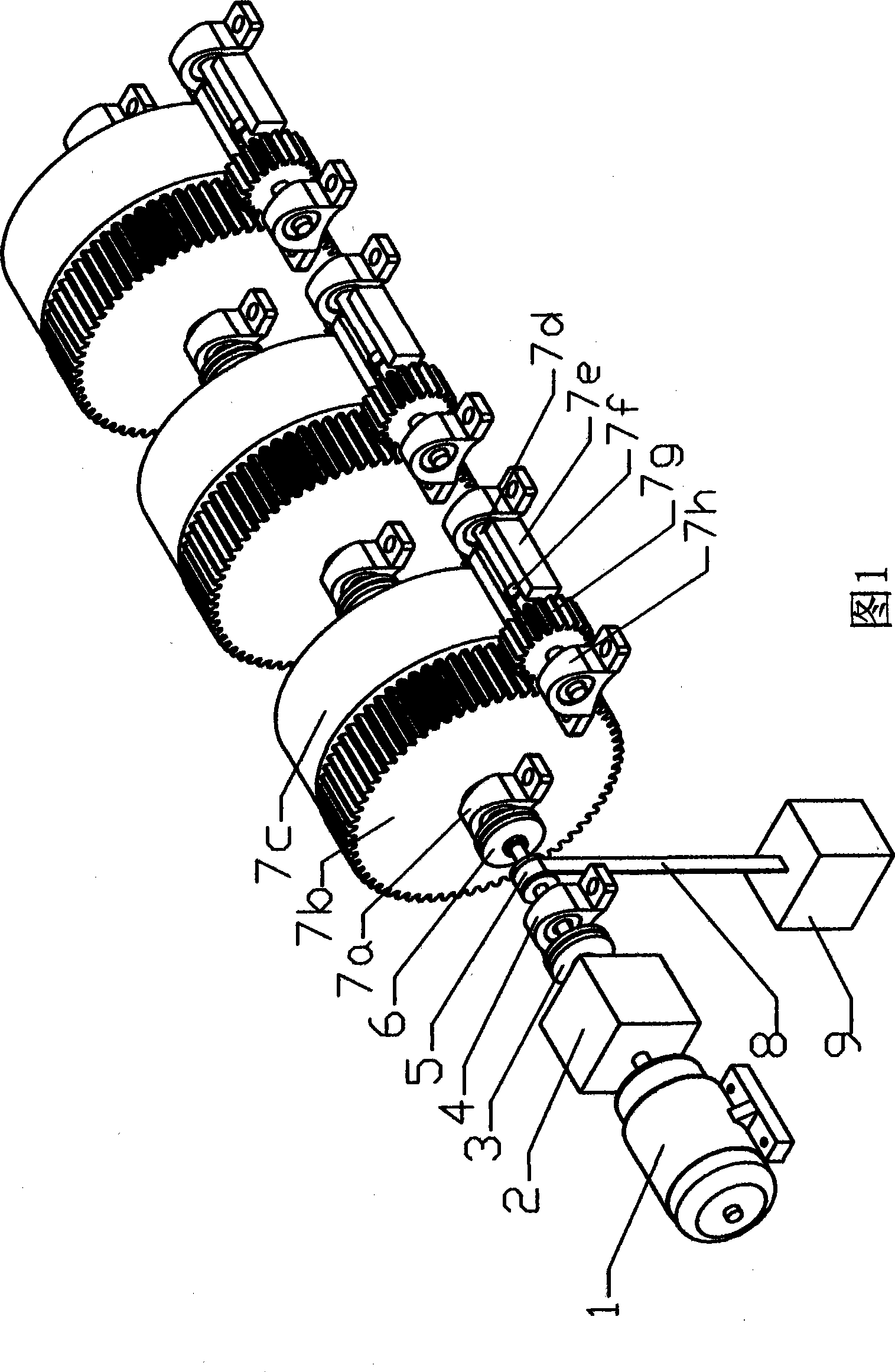

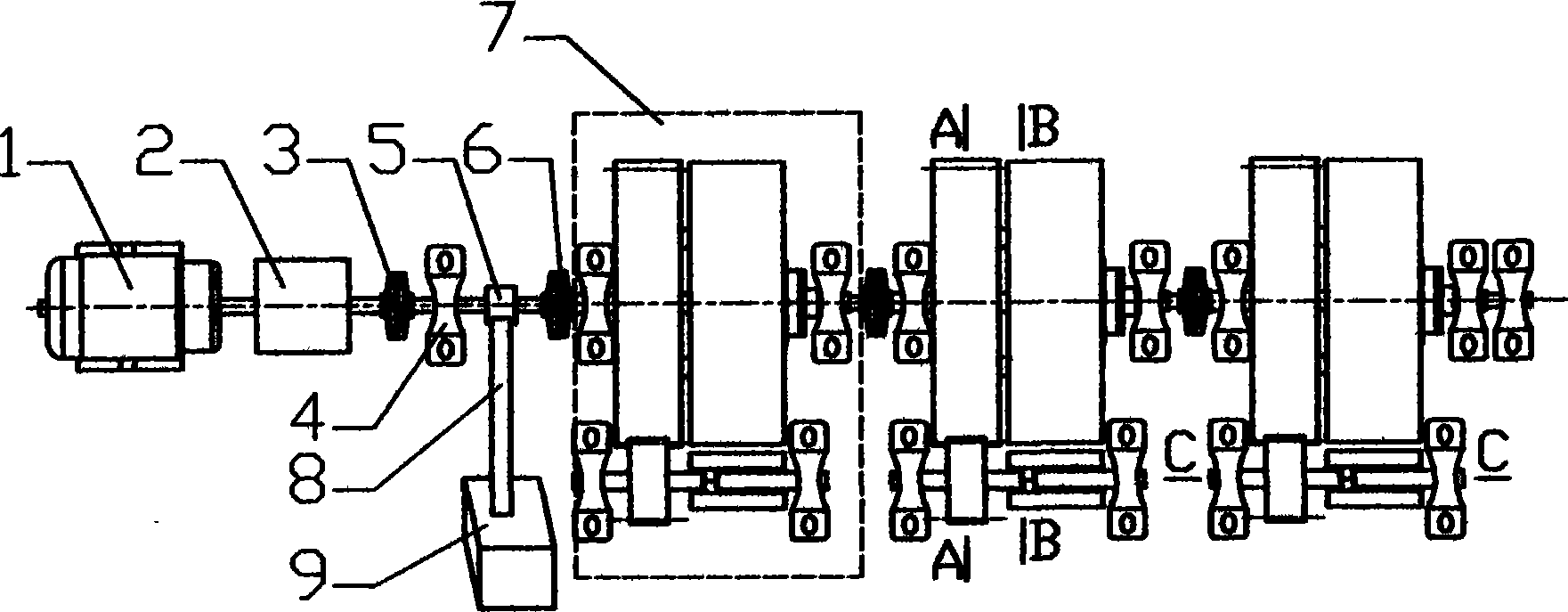

[0026] The structure of the kinematic mechanical energy storage and release device proposed by the present invention will be described in detail below according to the accompanying drawings, assuming that it is used for a mine hoist.

[0027] Figure 1, figure 2 with Image 6 Shown, a kind of motion mechanical energy storage and releasing device, it comprises machine base (not drawn), motor 1, reduction box 2, the load box 9 driven by reel 5 and steel rope 8, drives reel 5 to rotate and The driving shaft 10 is divided into left and right two sections by the reel 5, one of which is connected to the reduction box 2 through the clutch 3, and the other section is connected in parallel on the driving shaft 10 through several clutches 6 to store energy with a planar scroll spring 7m inside device7.

[0028] Such as Image 6 with Figure 7 As shown, the energy storage device 7 includes a driven shaft 12, a planar scroll spring 7m, an energy storage cylinder 7c, and a planetary gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com