Method for manufacturing digitally-designed removable dental prostheses and system required for this purpose

A technology for dental restorations, manufacturing methods, applied in the direction of dental prosthesis, dentistry, compression molding cups, etc., capable of solving problems that do not mention the methods or specified stages of manufacturing removable restorations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

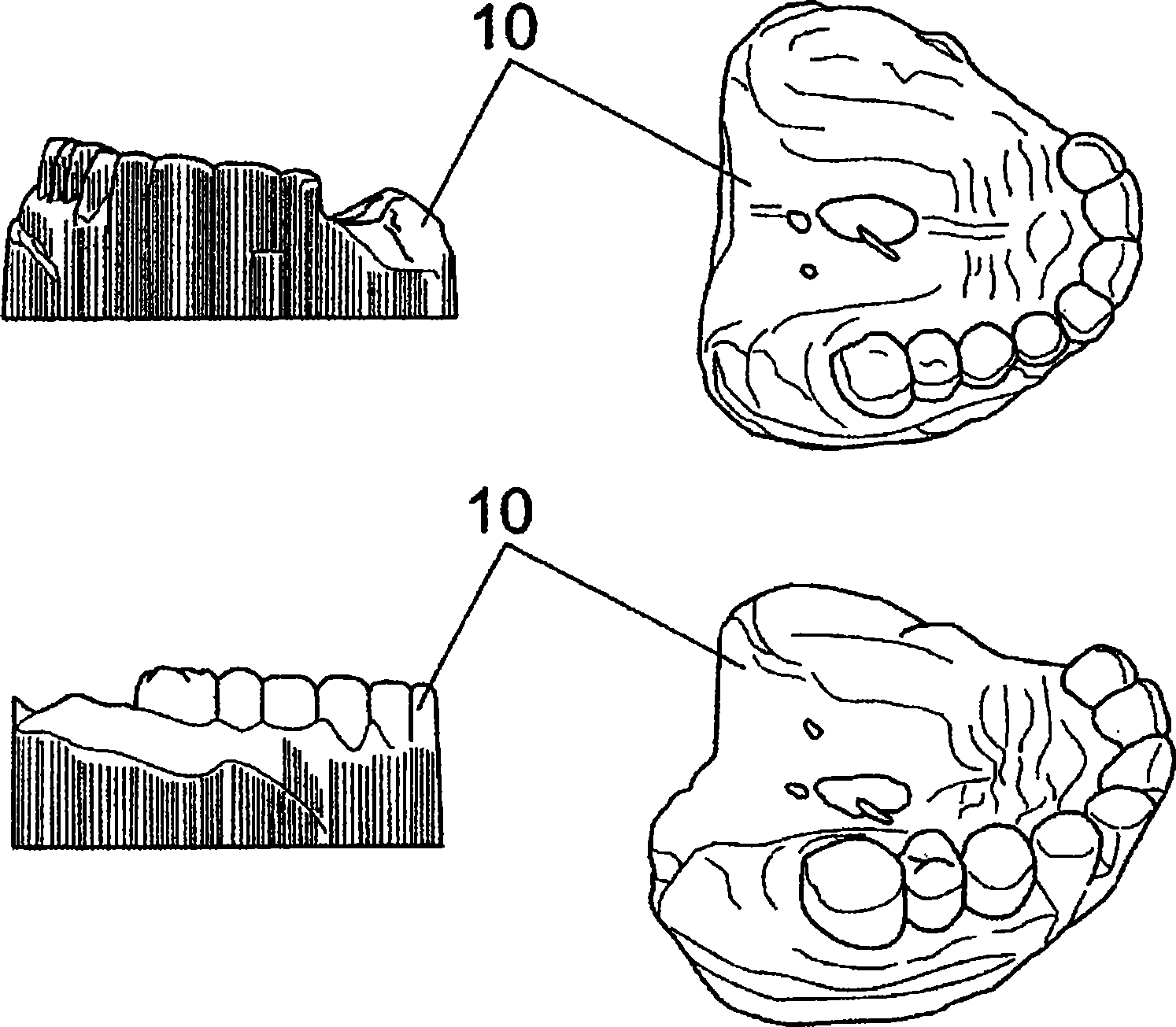

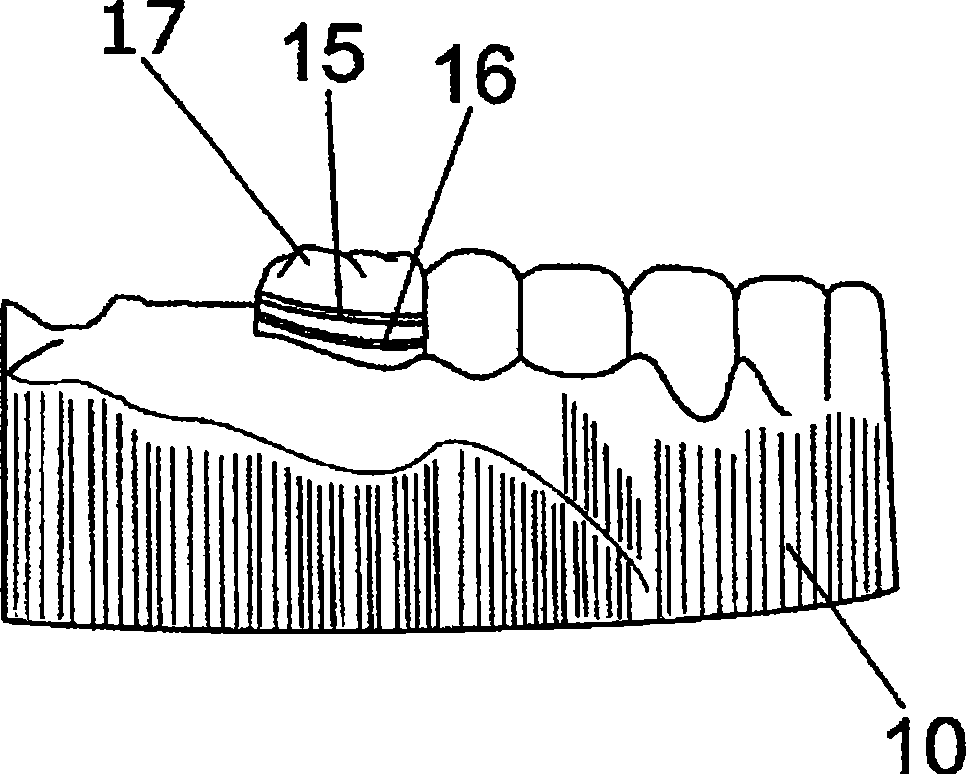

[0079] A preferred embodiment of the proposed invention is described below with reference to the accompanying drawings.

[0080] As noted previously, a system for manufacturing digitally generated removable dental restorations includes a scanner, a computing device or computer for the design and digital generation of removable restorations, and a manufacturing Manufacturing equipment for manufacturing metal parts by sintering powders. High-energy rays will be applied to the sintered powders.

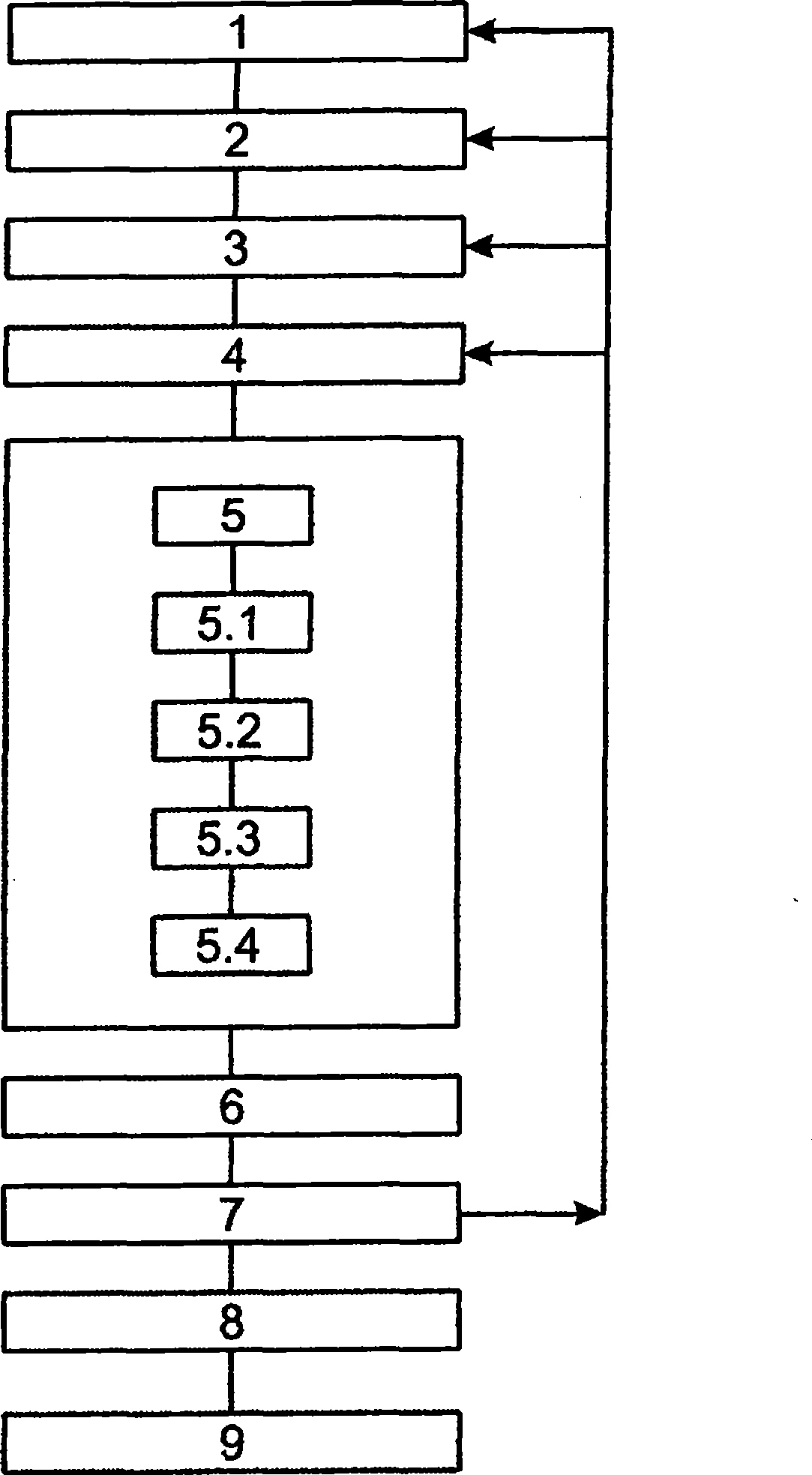

[0081] like figure 1 As shown, the method for the generation of a removable dental restoration begins with a scan of a model 1 of the patient's mouth; the method continues with the transfer of the generated file to a computing device or computer 2; the method then proceeds with a removable dental restoration Phases of the digital generation of the body.

[0082] Digital generation of removable dental restorations includes the following stages:

[0083] If there is a grid, in the area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com