Assembly drum of all-steel meridian large tyre-forming machine

A technology for forming machines and forming drums, which is applied in the field of forming drums for all-steel radial giant tire forming machines, can solve the problems of low strength of the stretchable parts of tile drum shoulders, inconvenient operation, manufacturing and installation, and complex structures, etc., so as to increase convenience, The effect of reducing labor intensity and simplifying the organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

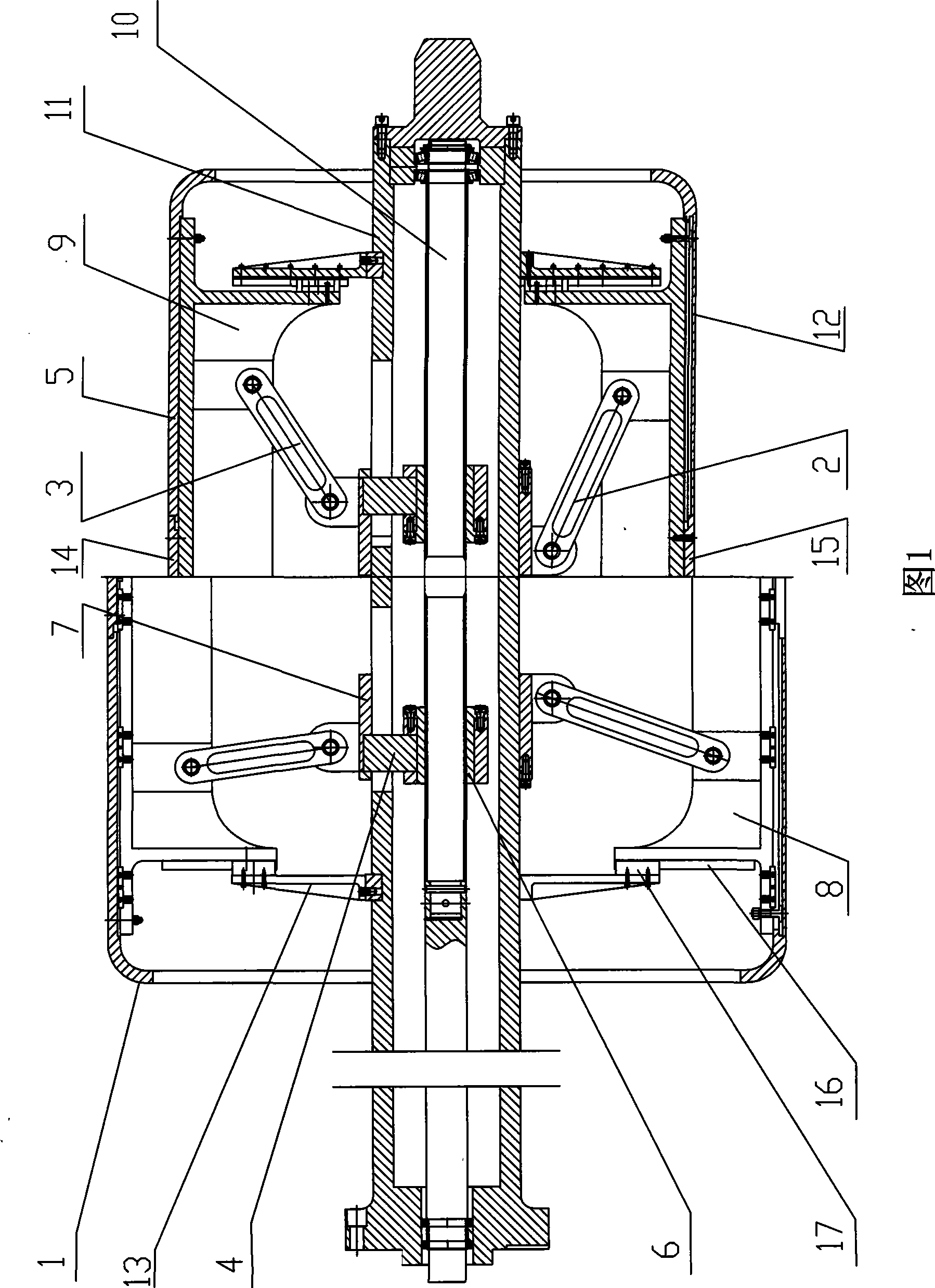

[0021] The building drum of the all-steel radial giant tire building machine of the present invention comprises 12 narrow drum tiles 5, 12 wide drum tiles 12, a power transmission mechanism, and a drum tile group expansion and contraction mechanism.

[0022] 1. Power transmission mechanism: including the hollow main shaft 11 and the screw rod 10. The left end of the hollow main shaft 11 is a flange surface, which is convenient to connect with the headstock. The screw rod 10 is built in the hollow main shaft 11. It consists of left and right opposite helical threads, and its two ends are respectively installed on the two end bearings in the hollow main shaft 11, and there are two left and right nuts 6 that cooperate with the screw mandrel 10 with reverse threads, respectively, as shown in Figure 1 .

[0023] 2. Expansion and contraction mechanism of the drum tile group: including two sets of narrow drum tile expansion and contraction mechanisms distributed symmetrically on both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com