Centrifugal pump body

A centrifugal pump and pump body technology, which is applied in the field of monitoring the running stability of centrifugal pumps, can solve the problems of reducing the structural strength of the position of the separator, affecting the normal operation of the entire pump, etc., and achieves the effect of prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

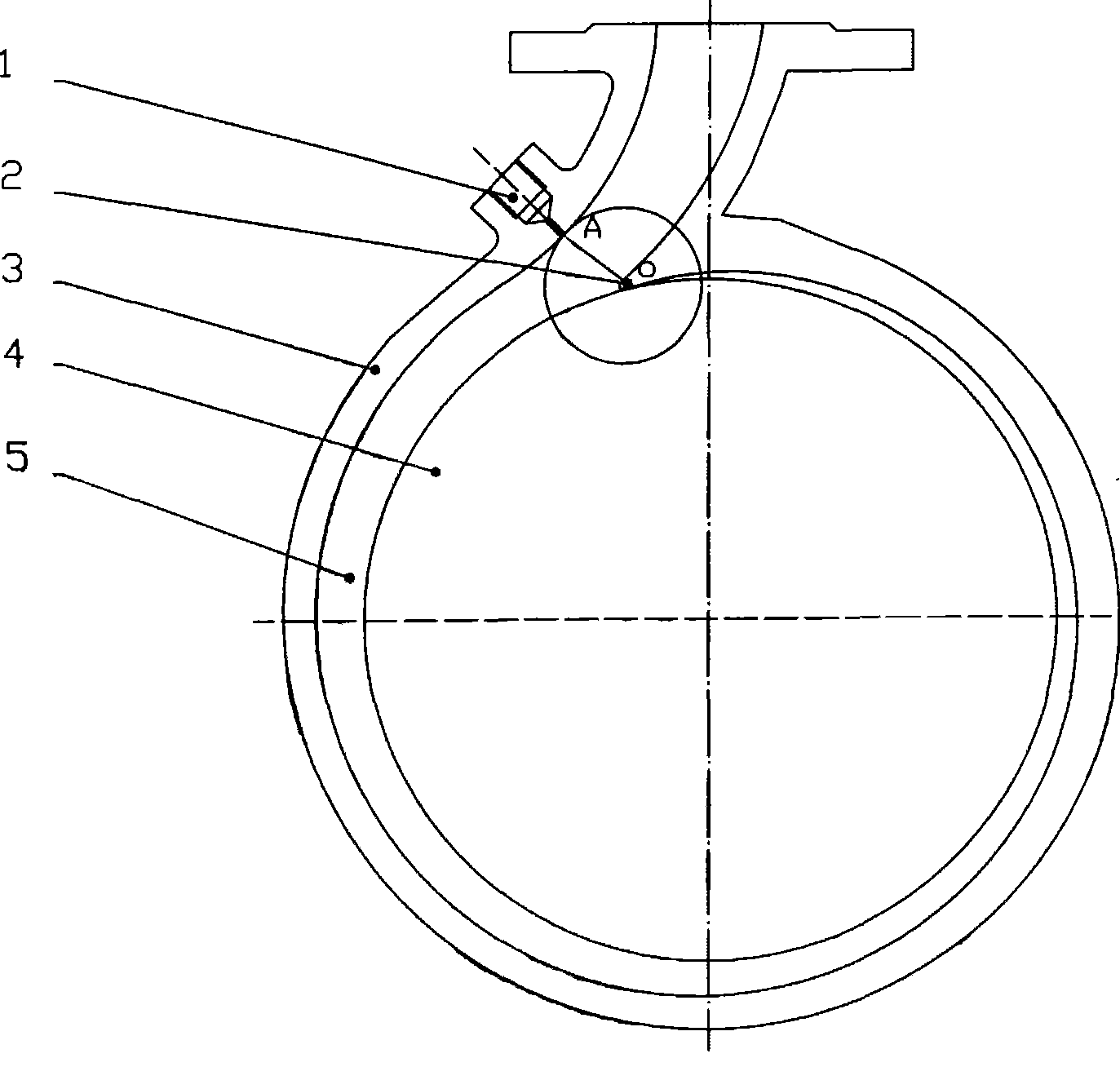

[0020] Such as figure 1 As shown, the pressure-taking hole 1 is set on the pump body 3 of the centrifugal pump. On the center section of the pump body of the centrifugal pump, an auxiliary circle is drawn with the point O on the end of the tongue 2 as the center of the circle, so that the auxiliary circle is in line with the inner wall of the pump body 3. Cut, the tangent point is recorded as point A, the present invention uses point A as the pressure taking point of the pressure taking hole 1 on the inner wall of the pump, and simultaneously uses the extension of the line segment OA as the center line of the pressure taking hole 1.

[0021] The pressure-taking hole 1 is designed as two ends. Looking from the outer wall of the pump body 3 to the inner wall, the diameter of the first section of the hole is G3 / 8, and the length is 15mm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com