Automatic feeding device of engine fuel

An automatic supply and engine technology, applied in the directions of oil supply device, engine components, engine control, etc., can solve the problem of high cost of transformation, and achieve the effect of improving work efficiency, simple manufacturing and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

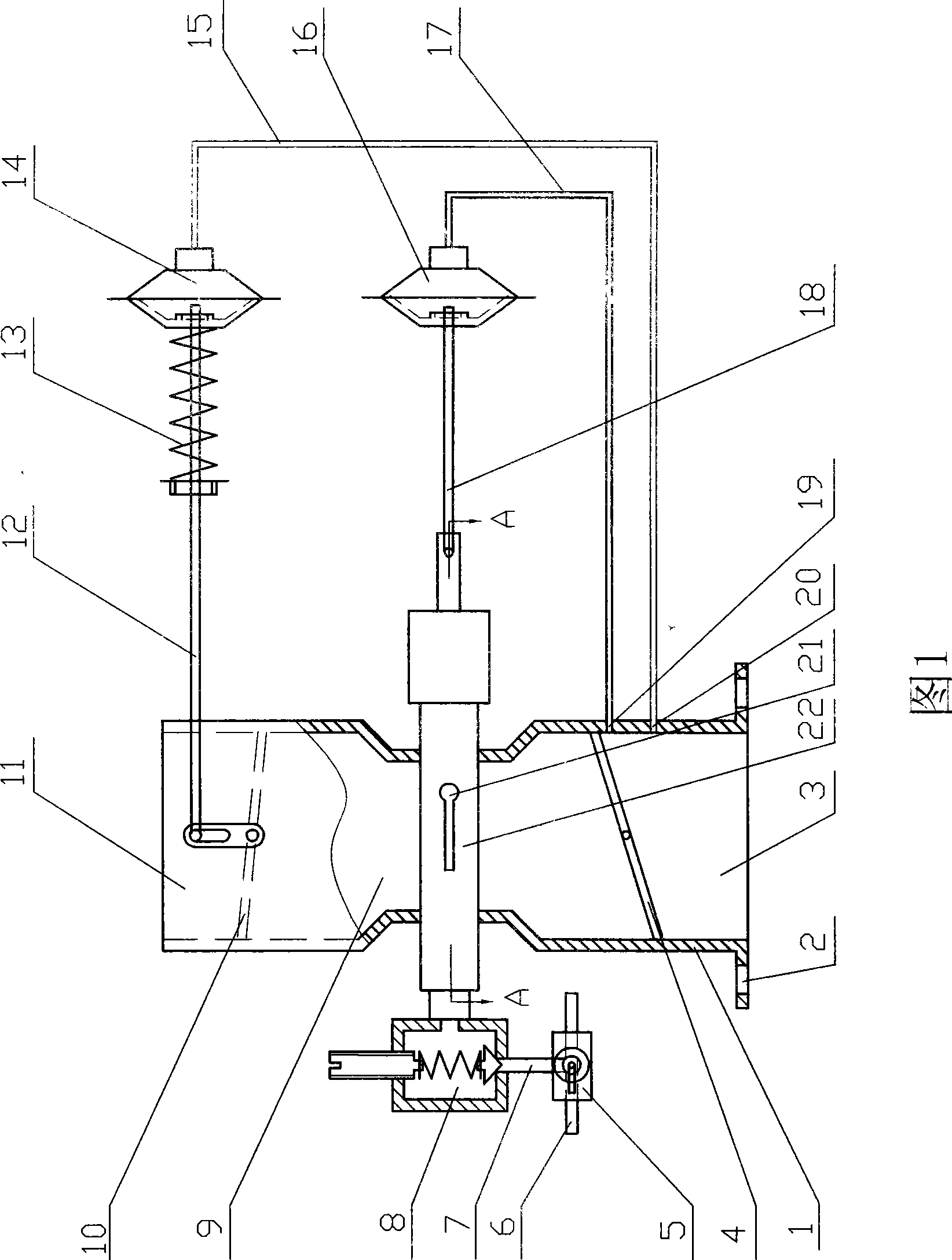

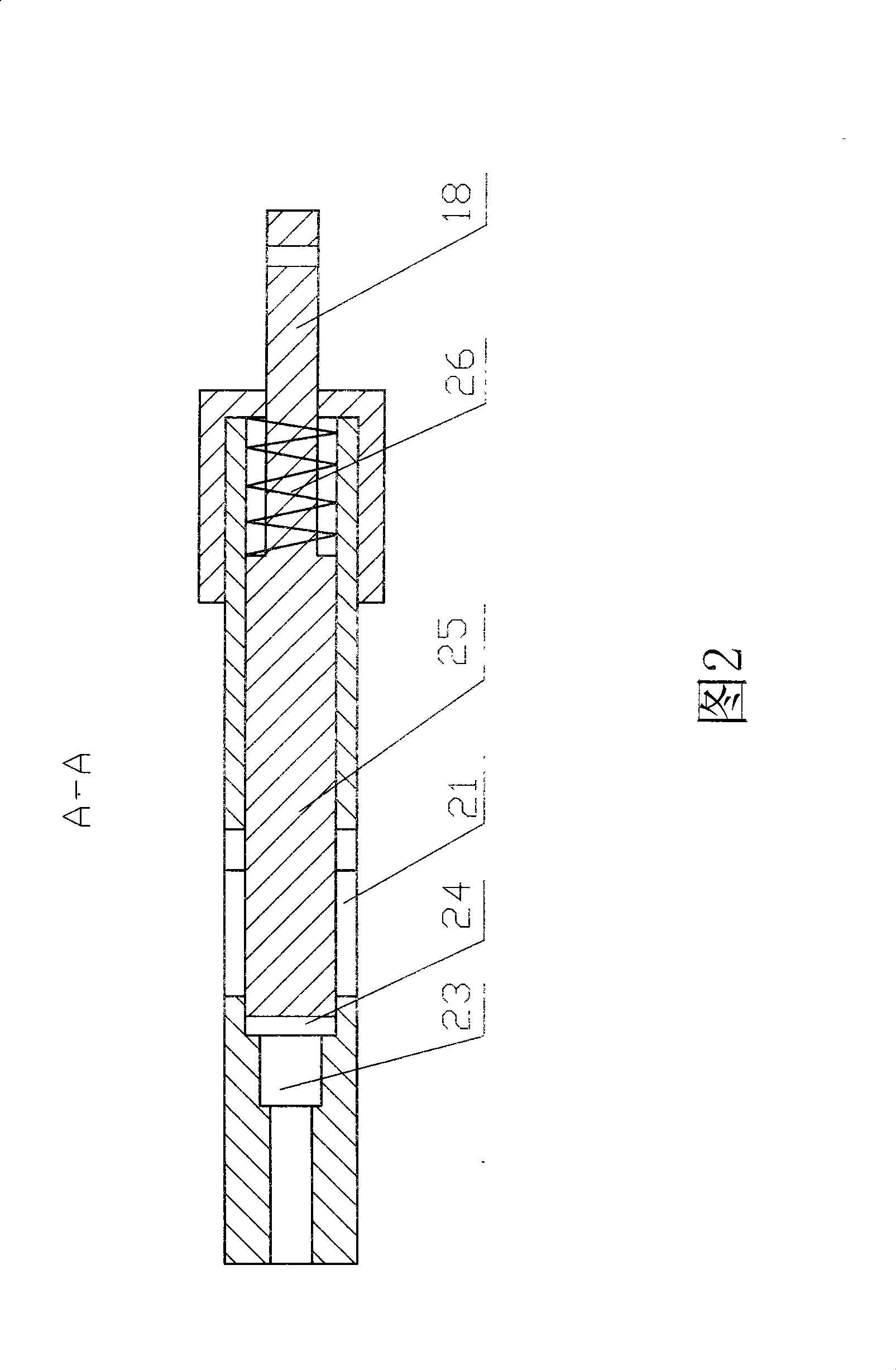

[0010] As shown in Figure 1, an automatic fuel supply device for an engine includes a mixer body (1) and a fuel control valve (5), and the two ends of the mixer body (1) are respectively provided with air inlets (11 ) and the mixed fuel outlet (3), a mixing chamber (9) is between the body inlet (11) and the mixed fuel outlet (3) of the mixer, and a mixing chamber (9) is provided at the end of the mixed fuel outlet (3) The installation hole (2) is connected, a choke valve (10) is installed on the air inlet (11), and a throttle valve (4) is installed on the mixed fuel outlet (3). When in use, the air inlet (11) of the mixer is assembled with the air filter, and the mixed fuel outlet (3) is sealed and connected with the air intake pipe of the engine cylinder through the connecting mounting hole (2).

[0011] In Fig. 1, the fuel control valve (5) is a conversion type control valve, and the conversion type fuel control valve is respectively provided with two fuel input ports (6) an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com