Metal embedded pressing bar for plate

A technology of embedment and metal, applied in elevators, covering/lining, construction and other directions in buildings, can solve the problems of not being able to recycle many times, not finding decoration and decoration, and not being able to disassemble, etc., to achieve multi-selectivity and human nature. Ease of design, installation and replacement of upholstery or trim panels with a simple and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

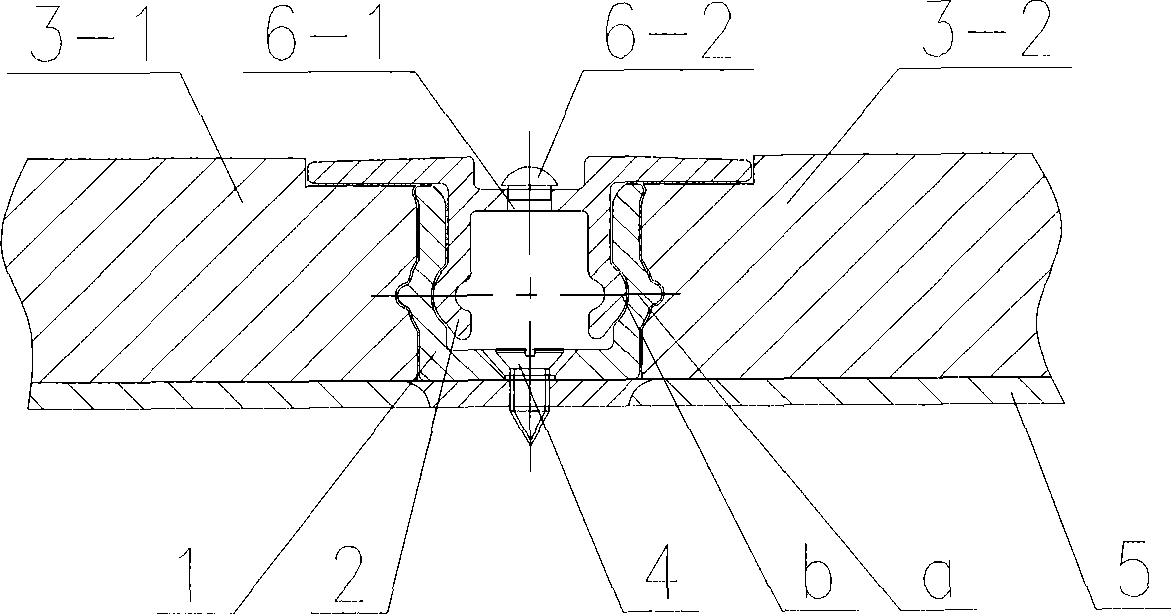

[0010] The technical contents and implementation methods of the present invention will be further described below in conjunction with the accompanying drawings.

[0011] attached figure 1 It is the best embodiment of the present invention. According to the drawings, the metal embedding strips for plates of the present invention include plates 3-1, 3-2, each embedding strip wherein includes a base 1 and a cover strip 2 that can be pressed and fastened on the base 1,

[0012] The base 1 and the cover strip 2 are snap-fit combined and can be disassembled and reassembled, wherein,

[0013] The base 1 is pre-attached and fixed on the wall 5 by self-tapping screws 4, and the wall 5 can be the inner wall of any building and any vertical wall, ground, top surface, etc. that need to be beautified or covered. .

[0014] The plates 3-1, 3-2 are respectively arranged on both sides of the base 1,

[0015] The cover strip 2 is crimped in the base 1 to realize the function of fixing th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com