Ceramet containing Ni-Cr binder and preparation thereof

A cermet and binder technology, applied in the field of cermet materials, can solve the problems of short service life, unstable structure and properties, unsatisfactory high temperature oxidation resistance, etc., and achieve the effect of low friction coefficient and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

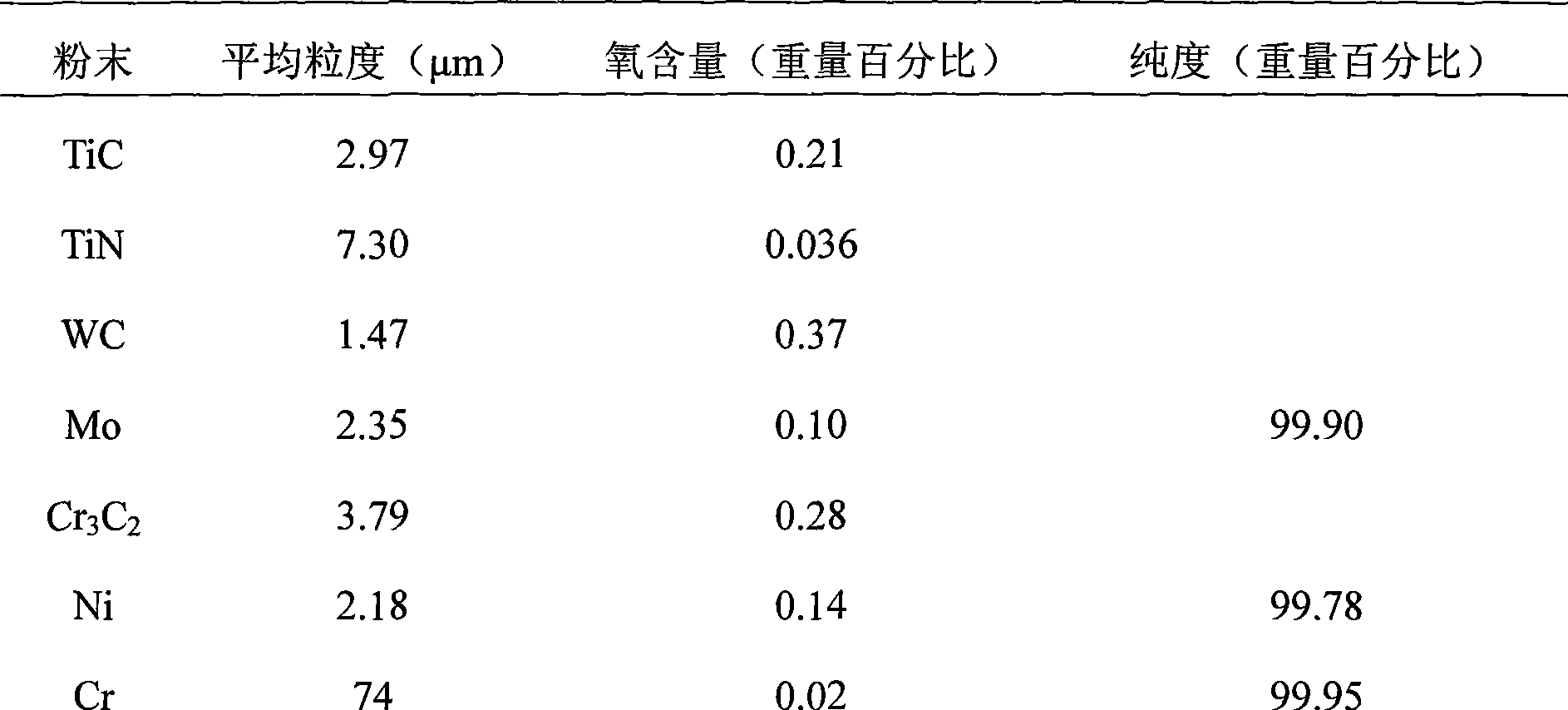

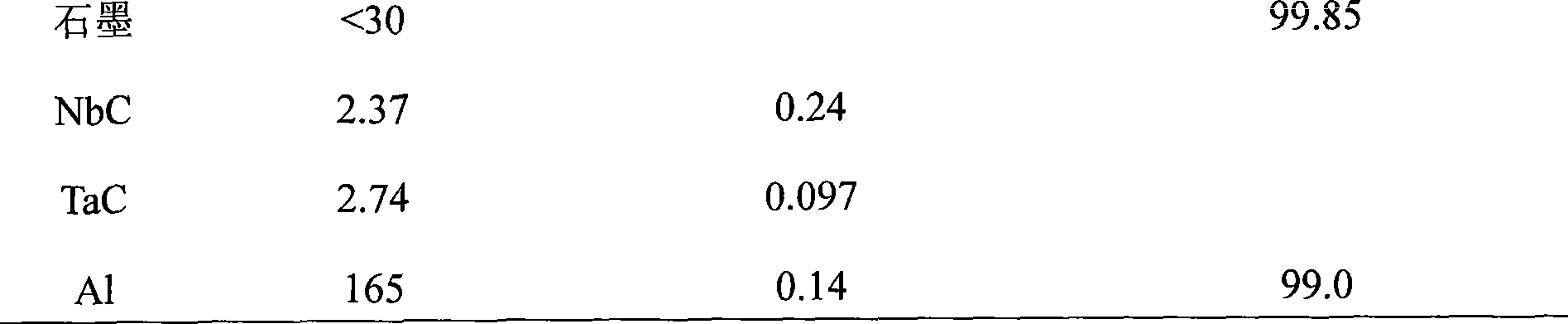

[0022] As shown in Table 2, for the cermets containing Ni binder of the five formulations of A1, A2, A3, A4 and A5 for comparison, TiC, TiN, WC, Mo, Cr in Table 1 were selected. 3 C 2 , Ni and graphite powder as raw material; B1, B2, B3, B4 and B5 of the present invention five kinds of formulas contain the cermet of Ni-Cr binder altogether, select TiC, TiN, WC, Mo, Cr in the table 1 for use 3 C 2 , Ni, Cr and graphite powder as raw materials. The specific preparation process of these ten kinds of cermets is as follows: first, the ingredients are mixed according to the ingredients shown in Table 2, and then ball milling is carried out according to the ball milling mixing process shown in Table 3 to obtain a mixed powder with uniform composition, and then an appropriate amount of polymer is added. Vinyl alcohol was molded according to the molding process shown in Table 3, and finally vacuum degreasing and vacuum sintering were carried out according to the vacuum degreasing and...

Embodiment 2

[0032] As shown in Table 5, C1, C2, C3, C4, C5, C6, C7, C8, C9 and C10 of the present invention have ten kinds of cermets containing Ni-Cr binder, and the TiC in Table 1 is selected. , TiN, WC, Mo, Cr 3 C 2, Ni, Cr, graphite, NbC, TaC and Al powders as raw materials. The specific preparation process of these ten kinds of cermets is as follows: first, batching is carried out according to the ingredients shown in Table 5, and then ball milling is carried out according to the ball milling mixing process shown in Table 6 to obtain a mixed powder with uniform composition, and then an appropriate amount of Polyvinyl alcohol was molded according to the molding process shown in Table 6, and finally vacuum degreasing and vacuum sintering were carried out according to the vacuum degreasing and vacuum sintering processes in Table 6 to obtain a dense sintered body, and the vacuum during vacuum degreasing and vacuum sintering degrees are less than 5Pa and 1×10 -1 Pa. The room-temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com