Fixing device for automobile seat belt

A technology for fixing devices and safety belts, which is applied in the direction of belt fixing devices, etc., can solve the problems of easy toppling of fixing bolts, increased cost, and large force, and achieves the effects of safe and reliable fixing, convenient welding, and enhanced strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

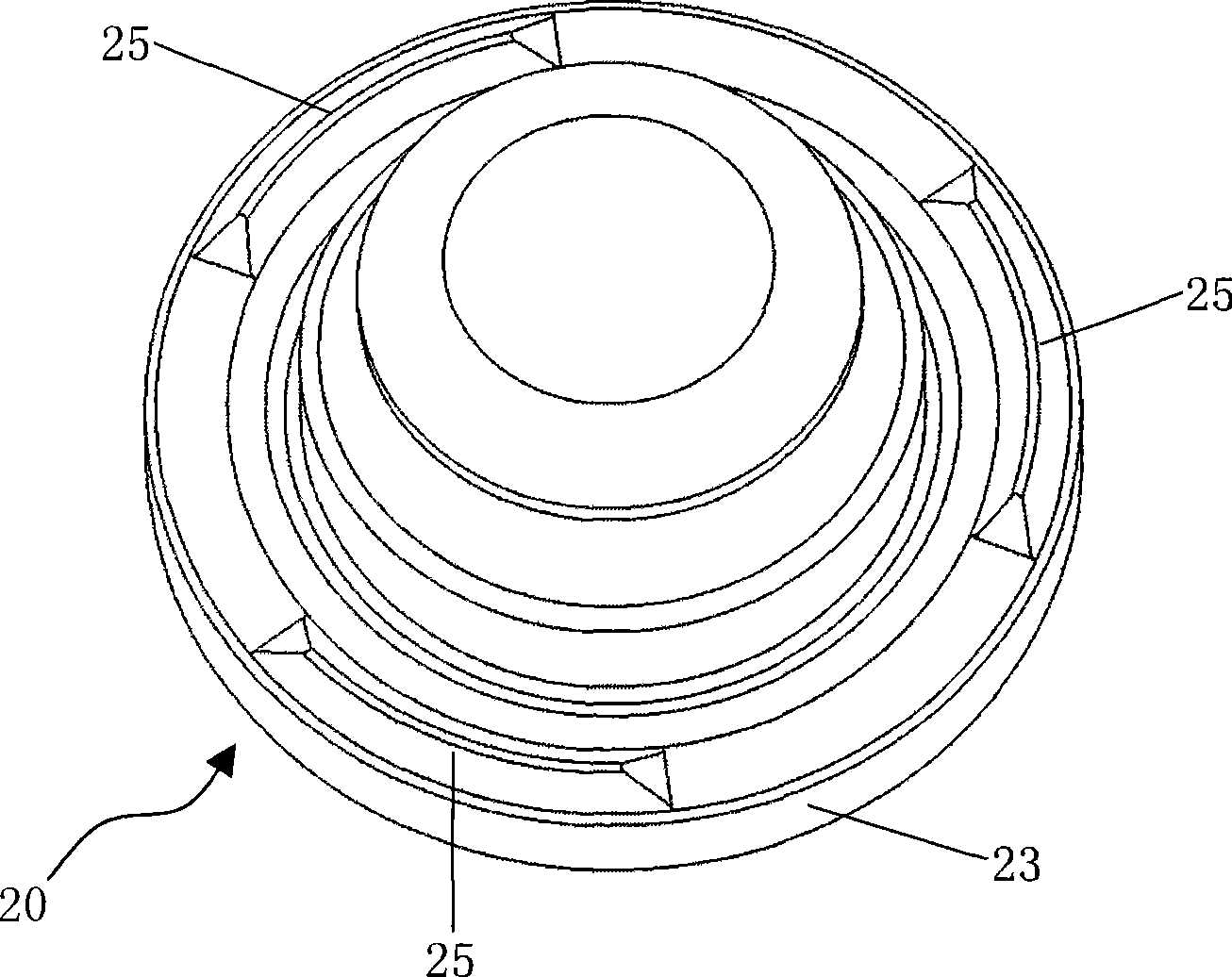

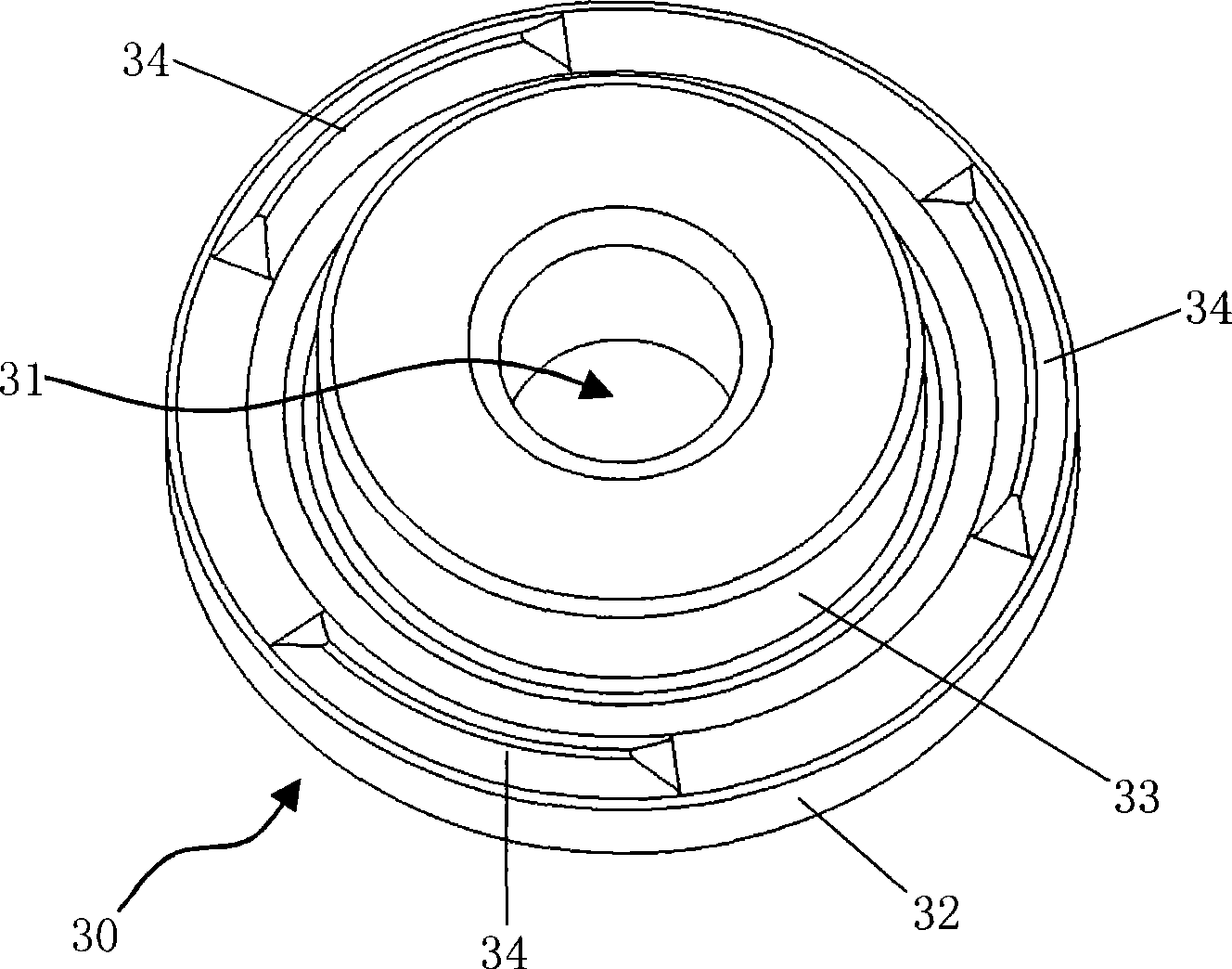

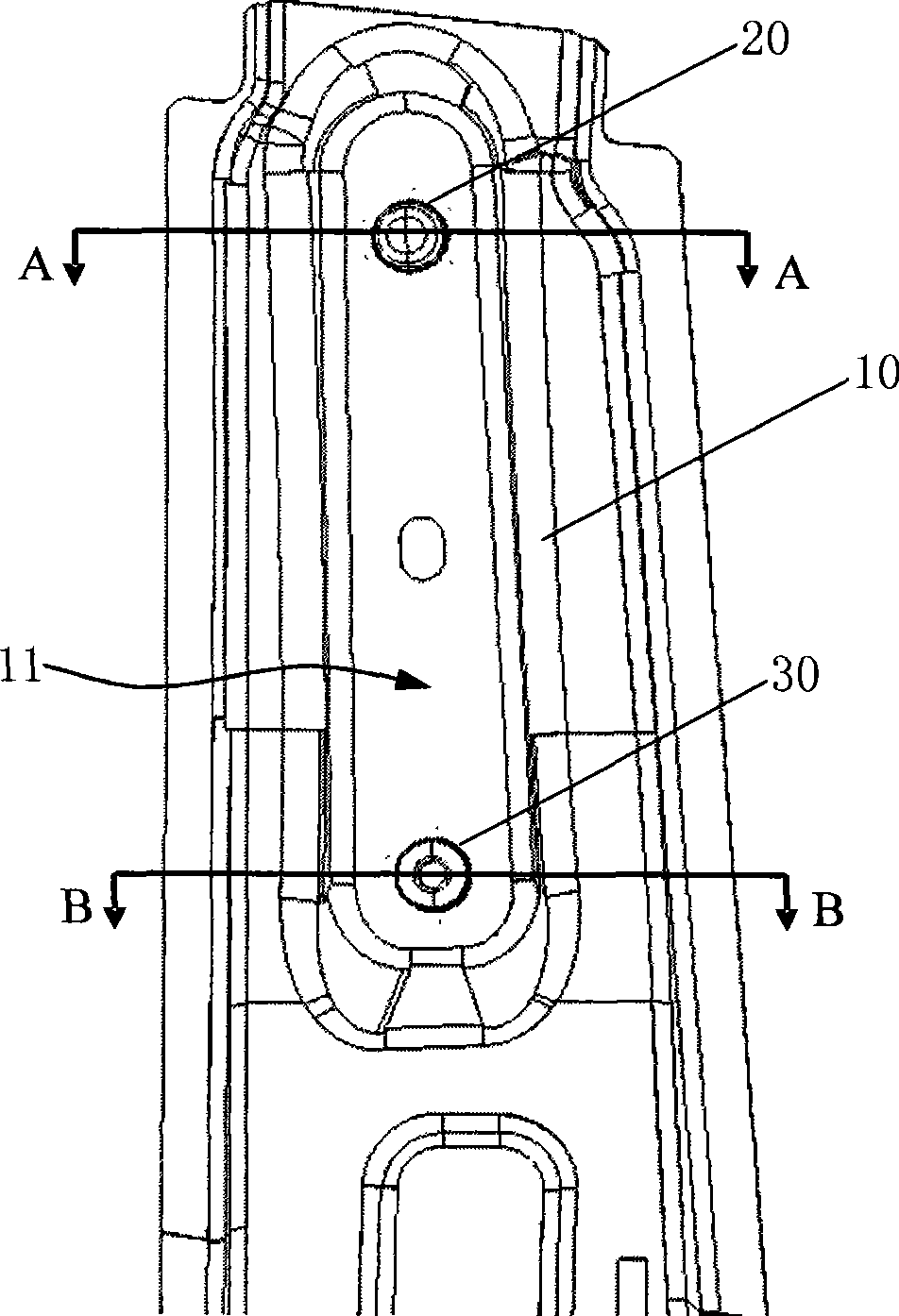

[0012] see Figure 3-7 , automobile seat belt fixing device, two bosses 20, 30 are welded on the side wall inner panel 10 of the B-pillar part, and the upper and lower ends of the safety belt adjustment slideway baffle plate 50 for installing the safety belt height adjuster are fixed on the bosses 20, 30 on. A ship-groove-shaped recess 11 is arranged on the side wall inner panel 10 of the B-pillar part. Welding bosses 20 and 30 are arranged on the upper and lower parts of this part. 20,30 implement fixed connection.

[0013] The boss 20 at the upper position is mushroom-shaped on one side of the safety belt adjustment slideway baffle plate 50, see figure 1 , 4 , 7, its root 21 cooperates with the orifice part that safety belt adjustment slideway baffle 50 top offers; Fixed on the post 30. The fixing method of this structure can conveniently fix the upper end of the seat belt adjustment slideway baffle 50 directly on the root 21 of the boss 20 by means of hooking, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com