Method for producing water type multicolor paint for water drum

A technology for colorful paint and production method, applied in the field of paint, can solve the problems of high cost of raw materials, pollute the environment, slow construction, etc., and achieve the effect of simple and fast construction method, low cost of raw materials, and small negative impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention introduces four embodiments according to steps respectively below.

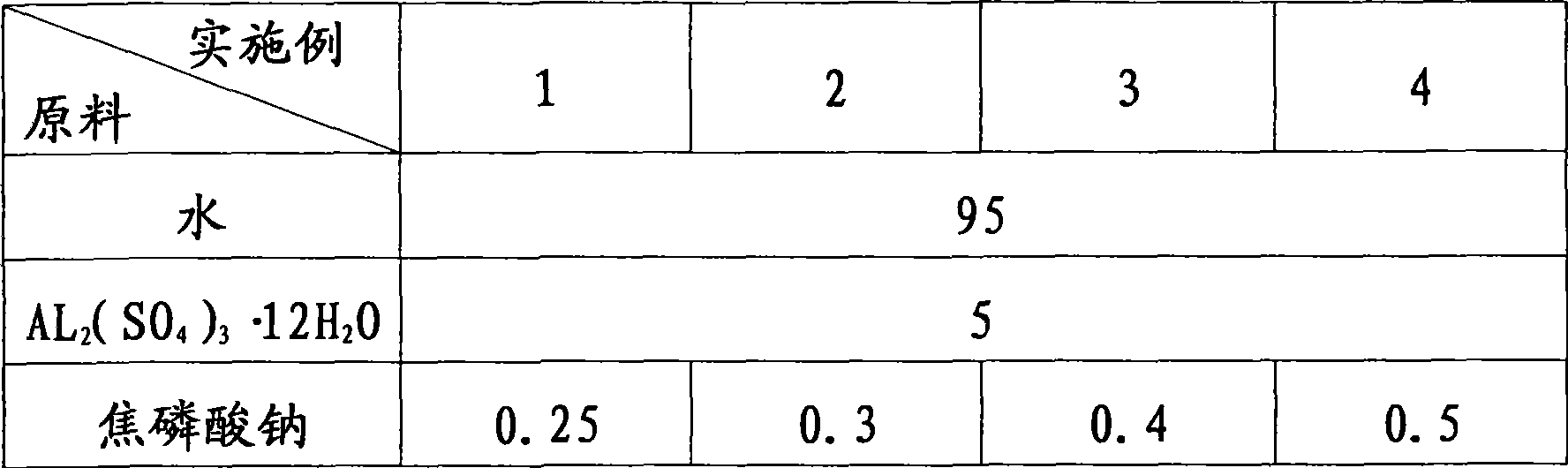

[0012] The first is the preparation example of the glue solution with 5% concentration, raw materials and proportioning weight list 1:

[0013] (Table 1)

[0014]

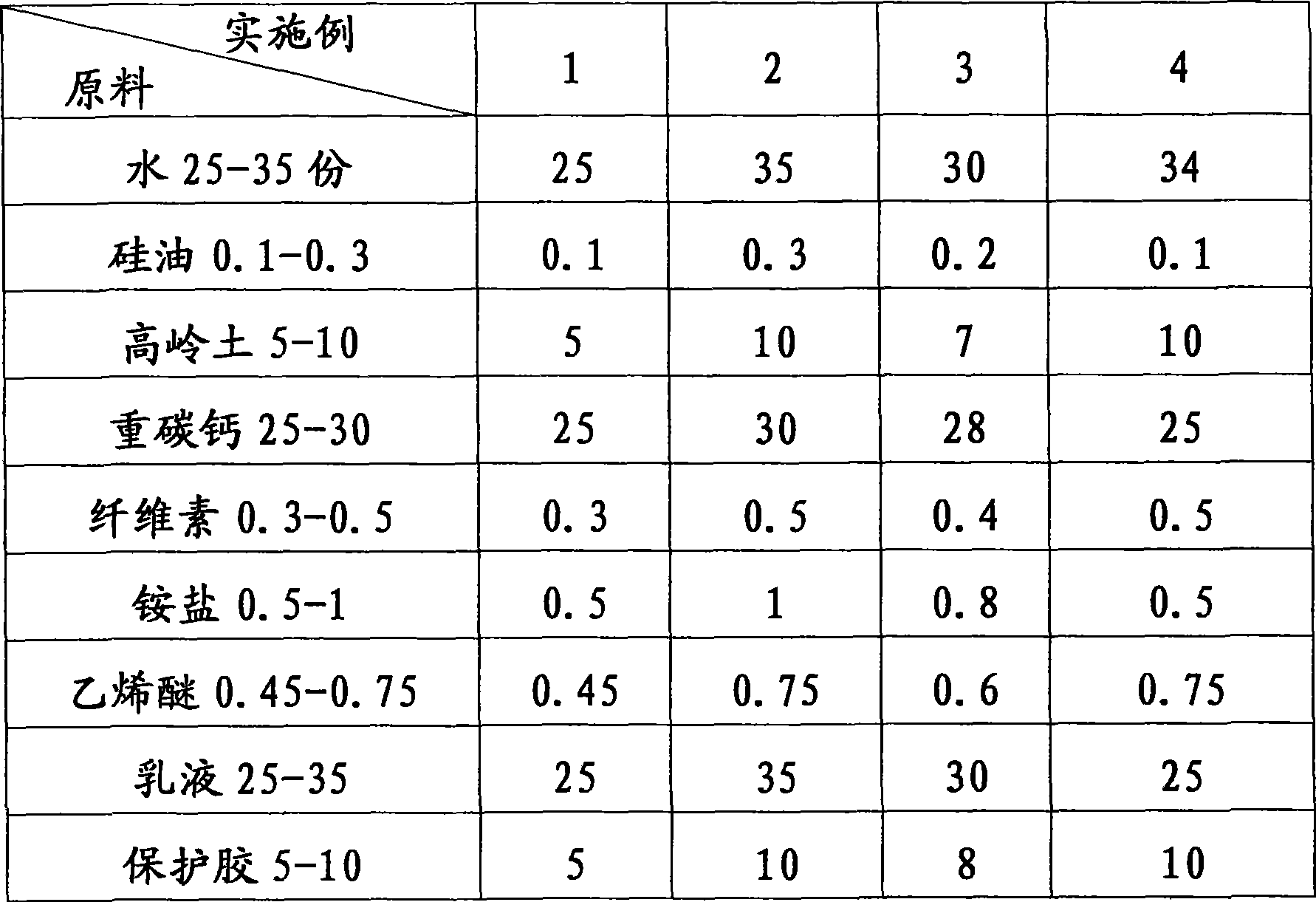

[0015] The 2nd, the preparation embodiment of white base paint, raw material and its proportioning by weight are listed in table 2, and table 2 and hereinafter are referred to as kaolin for short with water-washed kaolin, and heavy calcium carbonate is calcium heavy carbon, hydroxyethyl cellulose cellulose, polyacrylic acid ammonium salt is ammonium salt, alkylphenol polyoxyethylene ether is vinyl ether, pure acrylic elastic emulsion is emulsion, 5% concentration protective glue solution is protective glue.

[0016] (Table 2)

[0017]

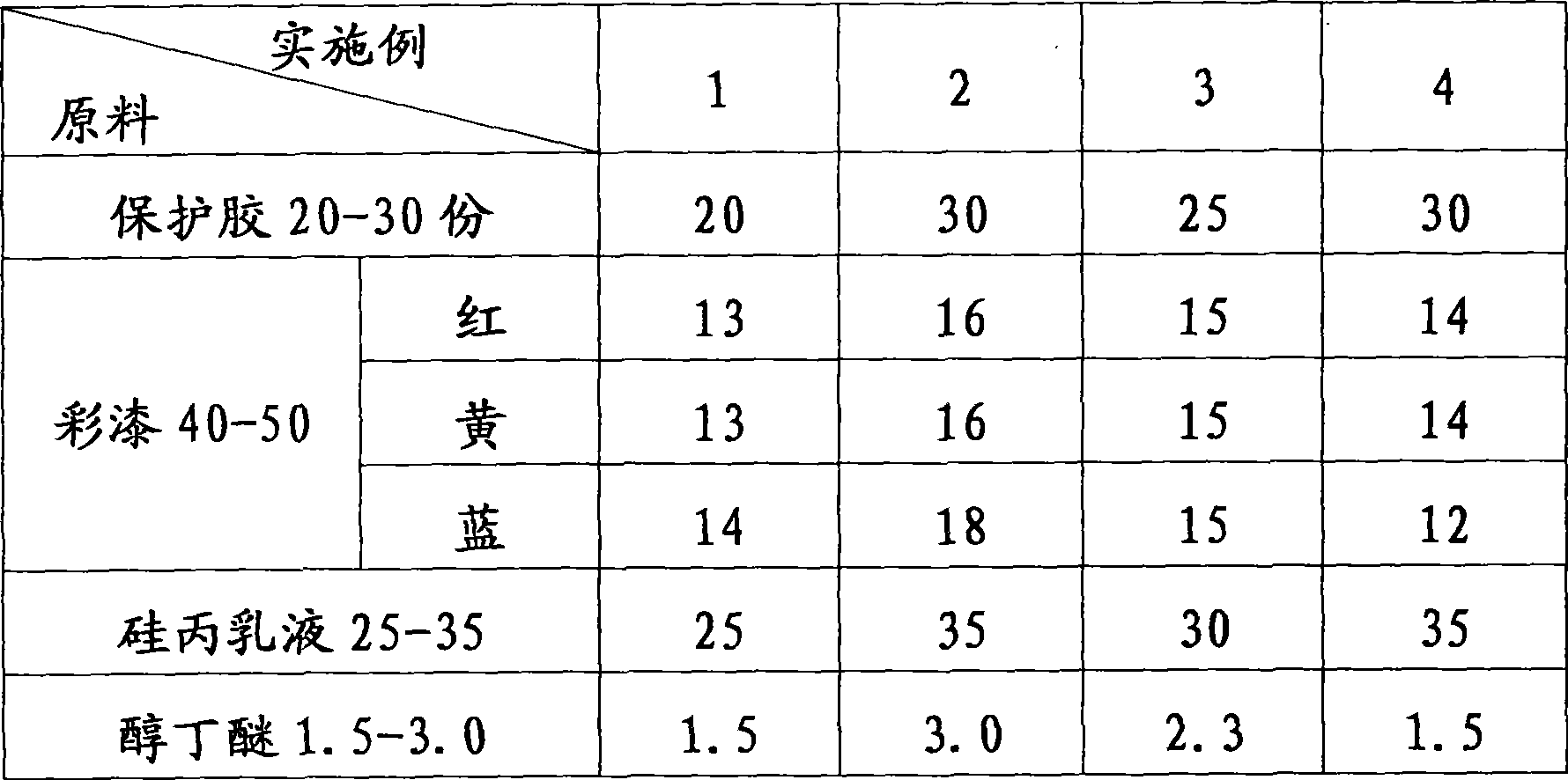

[0018] The 3rd, the embodiment of colored paint granulation, raw material and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com