Deflection drag-proof method for carriage hoisting operation

A trolley and anti-deviation technology, applied in cranes, optical devices, instruments, etc., can solve the problems of tower crane overturning, large overturning moment, etc., to prevent inclined pulling or inclined hanging, reduce the occurrence rate of accidents, and promote good promotion. The effect of applying value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in detail below.

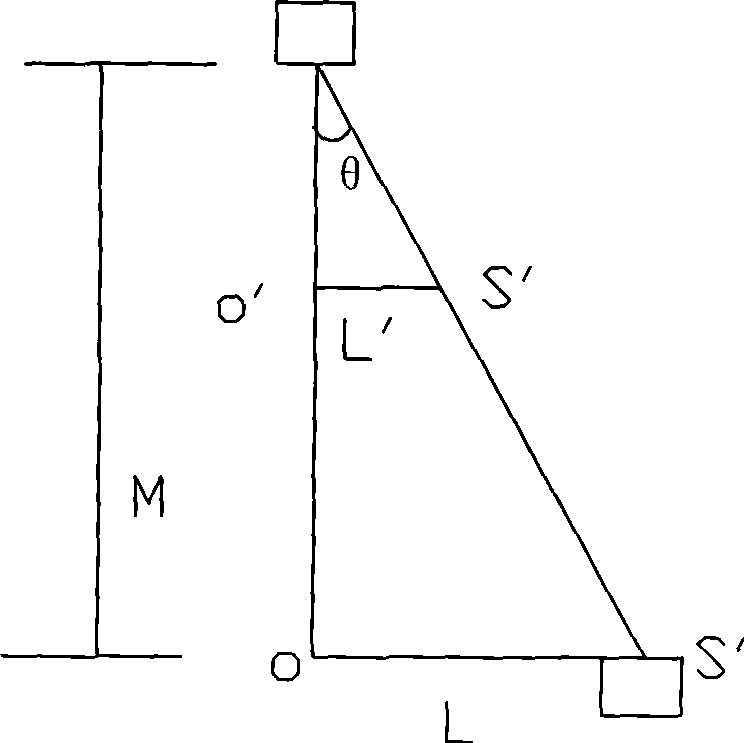

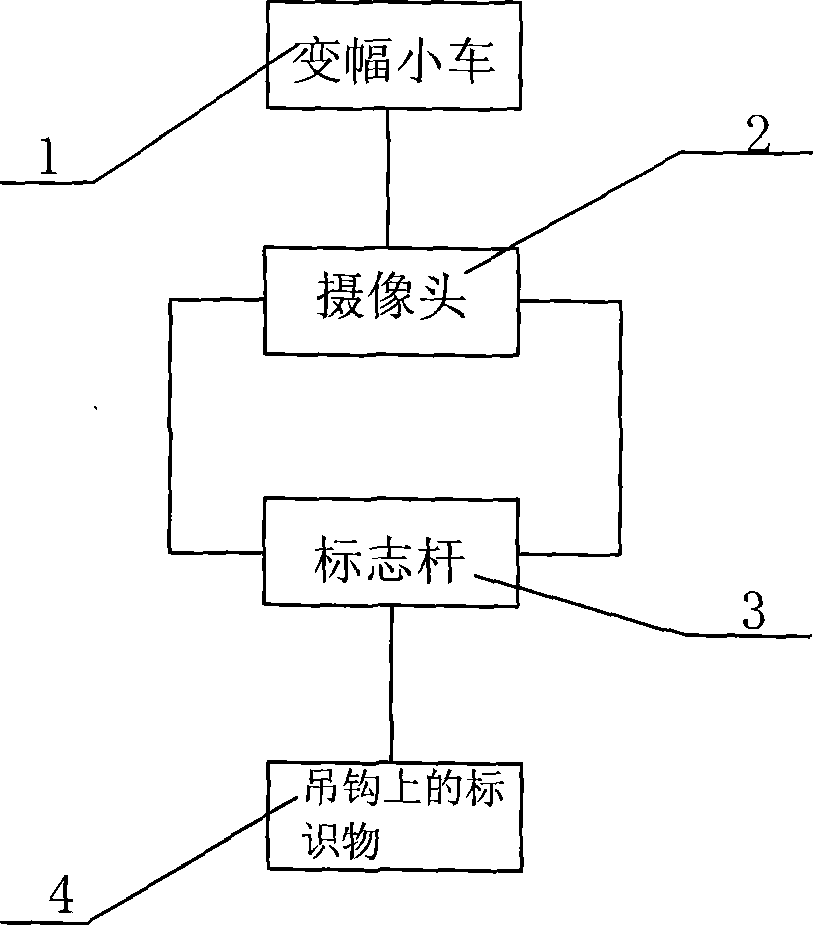

[0022] A method for preventing partial pull for trolley lifting operations, applied to tower cranes, such as image 3 As shown, it is specifically: a camera 2 is set directly below the trolley 1 of the tower crane, a sign pole 3 is set directly below the camera 2, the center of mass of the sign pole 3 is O′, and the distance from the camera 2 to O′ is O′. A marker 4 with obvious color and texture features is fixed on the hook, which is easy to be captured and distinguished by the camera 2 .

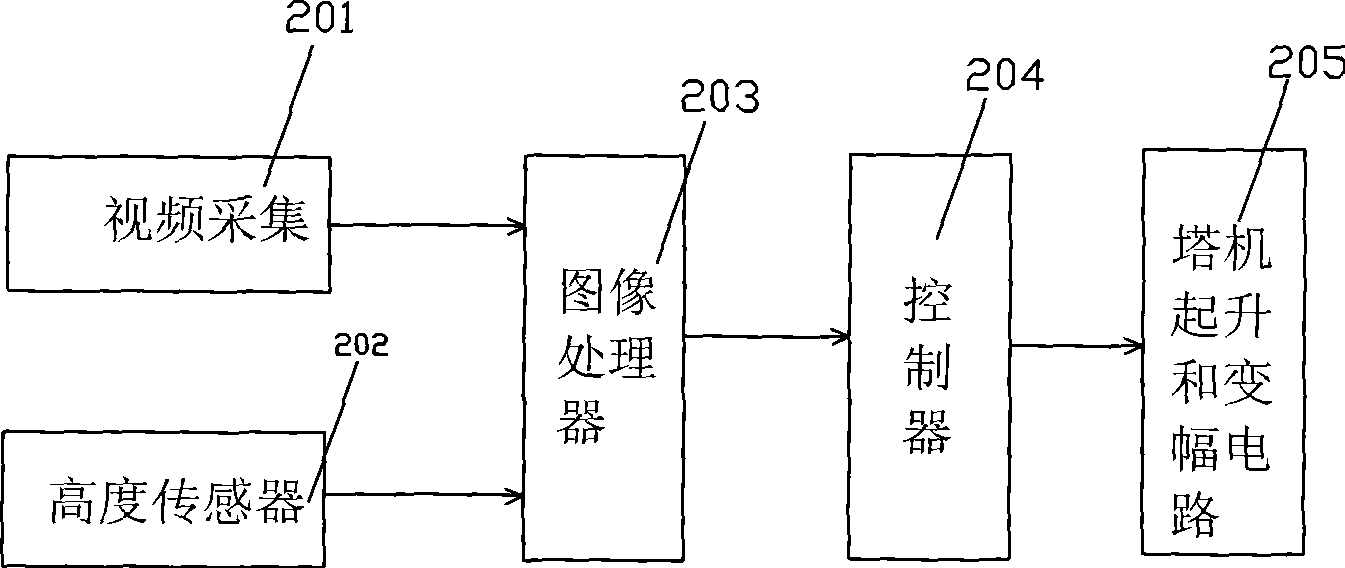

[0023] combine figure 2 , image 3 , figure 2 The middle video acquisition module 201 is equivalent to image 3 Camera 2 in . The camera 2 is connected with an image processor 203, and the image processor 203 is electrically connected with a controller 204, and the image processor 203 is used to process the information collected by the camera 2 and calculate the required angle value; the controller 204...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com