Rotary nozzle of washer

A technology of rotating nozzle and cleaning machine, applied in the field of rotating nozzle of cleaning machine and flushing equipment, can solve the problems of poor flushing effect, slow cleaning speed, small spraying range, etc., and achieve the effect of easy molding, fast cleaning speed and favorable spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

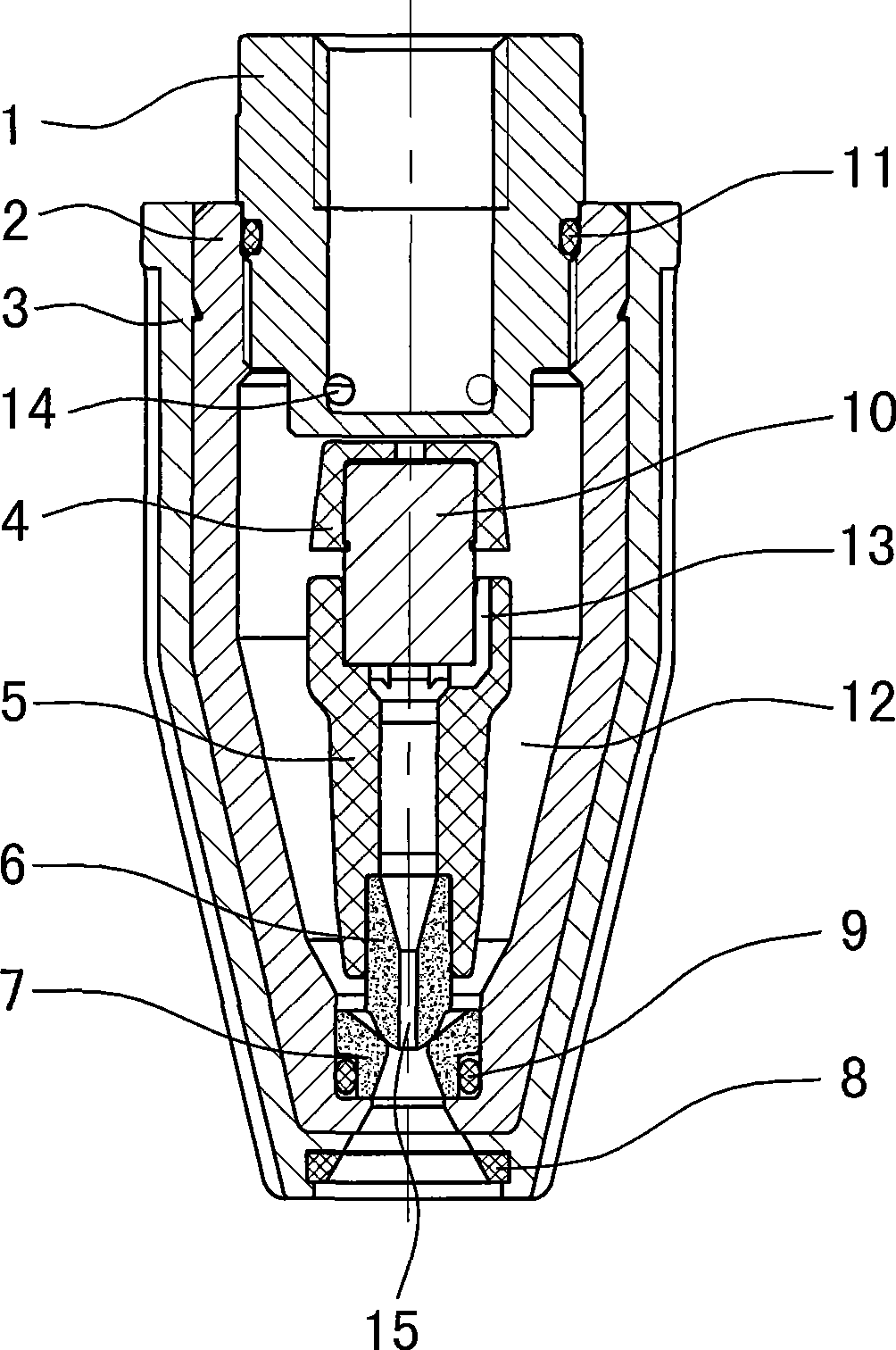

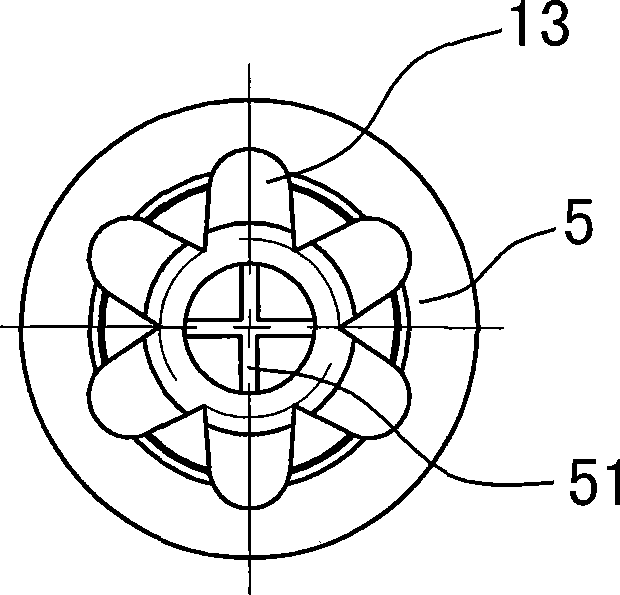

[0009] The invention discloses a rotating spray head of a washing machine, such as figure 1 , figure 2 As shown, a nozzle holder 1 is connected to the spray rod, and the nozzle holder 1 is connected to the nozzle cover 2. In order to increase the sealing performance, a sealing ring 11 can be installed between the nozzle holder 1 and the nozzle cover 2. There is a nozzle sheath 3 outside the nozzle cover 2 , There is a nozzle core 6 in the nozzle sleeve 2, and the nozzle core is made with a water spray hole 15. The nozzle core 6 is characterized in that a nozzle rotating seat 7 is installed in the head of the nozzle sleeve 2, and the nozzle core 6 is movably matched with the nozzle rotating seat 7, and the nozzle core 6 is connected The nozzle core sleeve 5, the nozzle core sleeve 5 is connected to the fixed pin 10, the fixed pin 10 has a pin cap 4, there is a spray channel 13 between the fixed pin 10 and the nozzle core sleeve 5, the nozzle core sleeve 5 and the nozzle sleeve The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com