Regeneration method of molecular sieve catalysts

A molecular sieve and catalyst technology is applied in the field of regeneration of molecular sieve catalysts, which can solve the problems that molecular sieve catalysts cannot be reused and the regeneration process is complicated, and achieve the effects of shortening the impregnation time, increasing the roasting temperature and improving the catalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Take the SiO containing 60 grams of initial silicon-aluminum molar ratio 2 / Al 2 o 3 (The same below) is a ZSM-5 molecular sieve catalyst of 30, after carrying out the catalytic cracking reaction of naphtha at 650°C for 4 hours, burning carbon for 2 hours under the condition that the air flow rate at 650°C is 400 ml / min, after cooling, use 0.1 The mole / liter oxalic acid solution was washed with water, filtered twice, and dried in an oven at 130°C to obtain a dealuminized and deactivated catalyst without carbon deposition. The silicon-aluminum molar ratio of SiO was determined by atomic absorption spectrometry. 2 / Al 2 o 3 for 80. Put it into 100 ml of 1 mol / L aluminum sulfate solution and stir at a constant temperature of 50°C for 1 hour, then put it in an oven and dry it at 120°C for 2 hours, then put it in a muffle furnace, and bake it at 800°C for 5 hours under a nitrogen atmosphere , the sample was taken out and cooled, washed twice with distilled water, and dr...

Embodiment 2~7

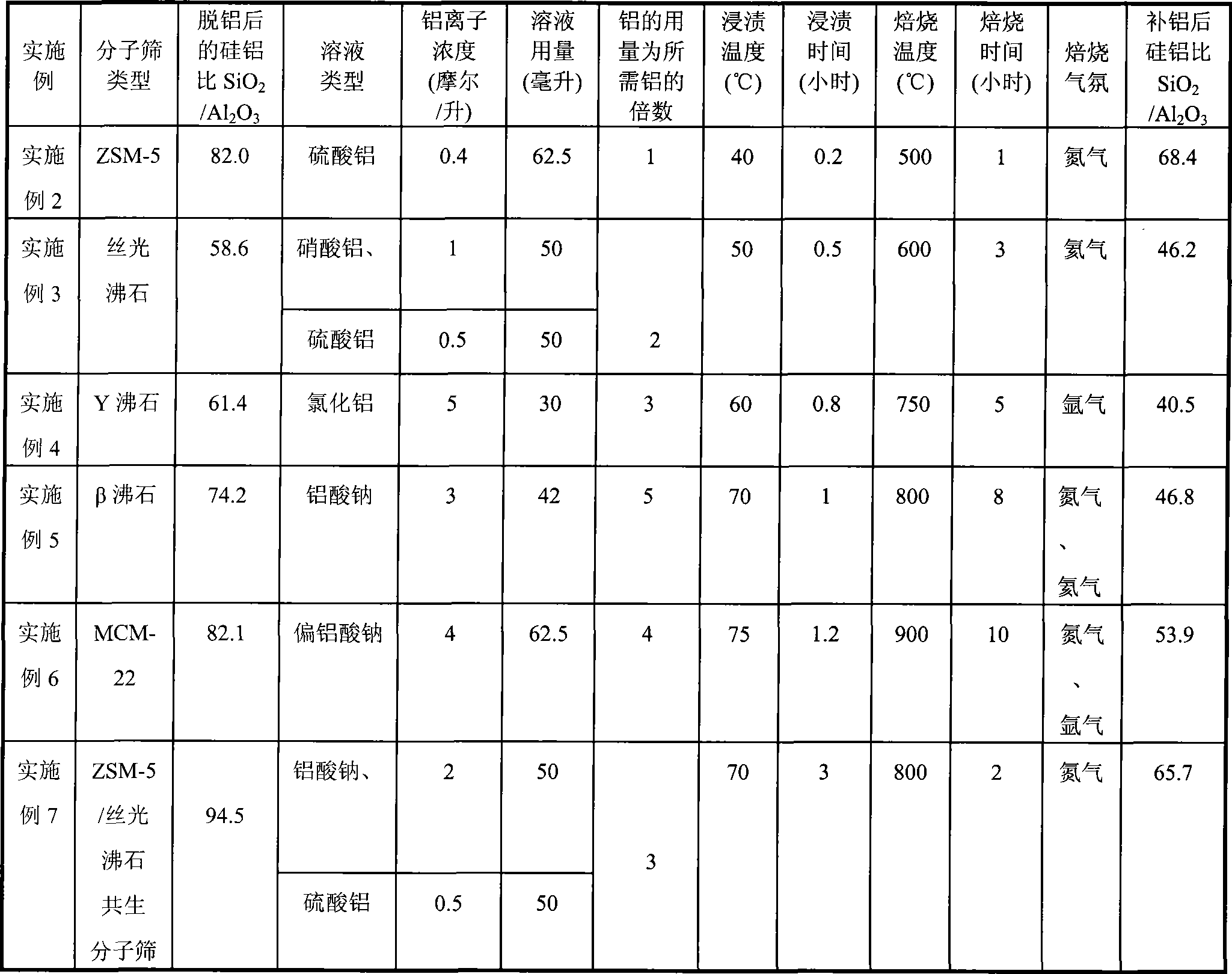

[0020] According to the method and content provided in Example 1, the aluminum supplementation conditions are shown in Table 2, and the silicon-aluminum ratio before and after aluminum supplementation was measured by atomic absorption spectroscopy, and the catalyst after aluminum supplementation was obtained, as shown in Table 2.

[0021] Table 2

[0022]

Embodiment 8

[0024] Aluminum supplementation was carried out according to the method of Example 7, and the aluminum supplementation was repeated 3 times before washing with distilled water. The prepared catalyst SiAl molar ratio SiO 2 / Al 2 o 3 is 56.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com