Method for producing architectural materials by using paper making sludge

A technology for papermaking sludge and building materials, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the environmental pollution of papermaking sludge and other problems, and achieve the effect of low cost, good performance and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The papermaking sludge from a paper mill in Zibo is selected as the main raw material, and its chemical composition and weight percentage are:

[0031]

[0032] Industrial quicklime is selected as the auxiliary raw material, and its main component is CaO.

[0033] Take 60kg of papermaking sludge, 40kg of quicklime, 100kg of raw materials, crush them, add water, mix them evenly, and press them into 76×38×8mm 3 of semi-finished panels. Industrial waste gas carbon dioxide is used for accelerated carbonization treatment, the concentration of carbon dioxide is 35% by weight, and the accelerated carbonization temperature is 30-80°C. After 2 hours of reaction, the finished plate is made.

[0034] After accelerated carbonization, the weight increase is to absorb about 8% of carbon dioxide, and the carbonization rate exceeds 16%. The flexural strength of the carbonized papermaking sludge sheet is about 3MPa, and the compressive strength is about 12MPa.

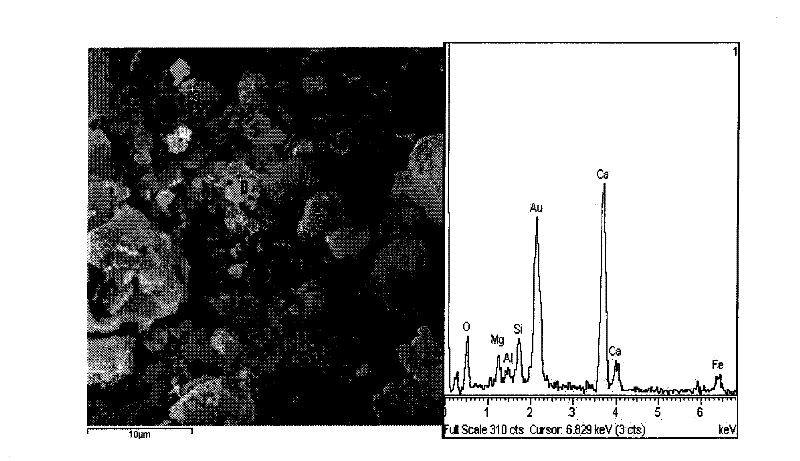

[0035] The XRD ana...

Embodiment 2

[0038] Select papermaking sludge (same as Example 1) and steel slag from Jinan Iron and Steel Group as main raw materials. The chemical composition and weight percentage of steel slag are:

[0039]

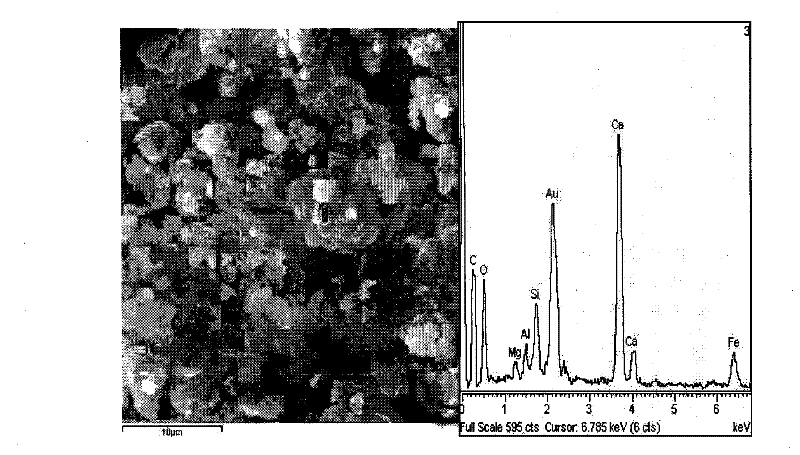

[0040] Take 25kg of papermaking sludge, 75kg of steel slag, and crush 100kg of raw materials, add water, mix evenly, and press into 76×38×12mm 3 of semi-finished bricks. Industrial waste gas carbon dioxide is used for accelerated carbonization treatment, the concentration of carbon dioxide is 35% by weight, the pressure of carbon dioxide gas is 2.5bar, and the accelerated carbonization temperature is 30-60°C. After 6 hours of reaction, the finished brick is made.

[0041] After accelerated carbonization, the weight increases by absorbing about 10% of carbon dioxide, and the carbonization rate exceeds 20%. The flexural strength of carbonized paper sludge brick is about 4MPa, and the compressive strength is about 17MPa.

Embodiment 3

[0043] Select papermaking sludge (same as Example 1), steel slag (same as Example 2), lime and waste cement concrete as raw materials. The chemical composition and weight percentage of waste concrete are:

[0044]

[0045] Take 35kg of paper-making sludge, 20kg of steel slag, 20kg of lime and 25kg of waste concrete, crush 100kg of raw materials, add industrial lime water, mix evenly, and press into 76×38×12mm 3of semi-finished bricks. Industrial waste gas carbon dioxide is used for accelerated carbonization treatment, the concentration of carbon dioxide is 25% by weight, the pressure of carbon dioxide gas is 4bar, and the accelerated carbonization temperature is 30-60°C. After 14 hours of reaction, the finished brick is made.

[0046] After accelerated carbonization, the weight increases by absorbing about 5% of carbon dioxide, and the carbonization rate exceeds 10%. The flexural strength of carbonized papermaking sludge bricks is about 2.5MPa, and the compressive strengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com