Polycrystalline silicon purification or silicon liquid leakage defense device of ingot furnace

A protection device, polysilicon technology, applied in the direction of polycrystalline material growth, furnace, crystal growth, etc., to achieve the effect of avoiding dangerous situations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

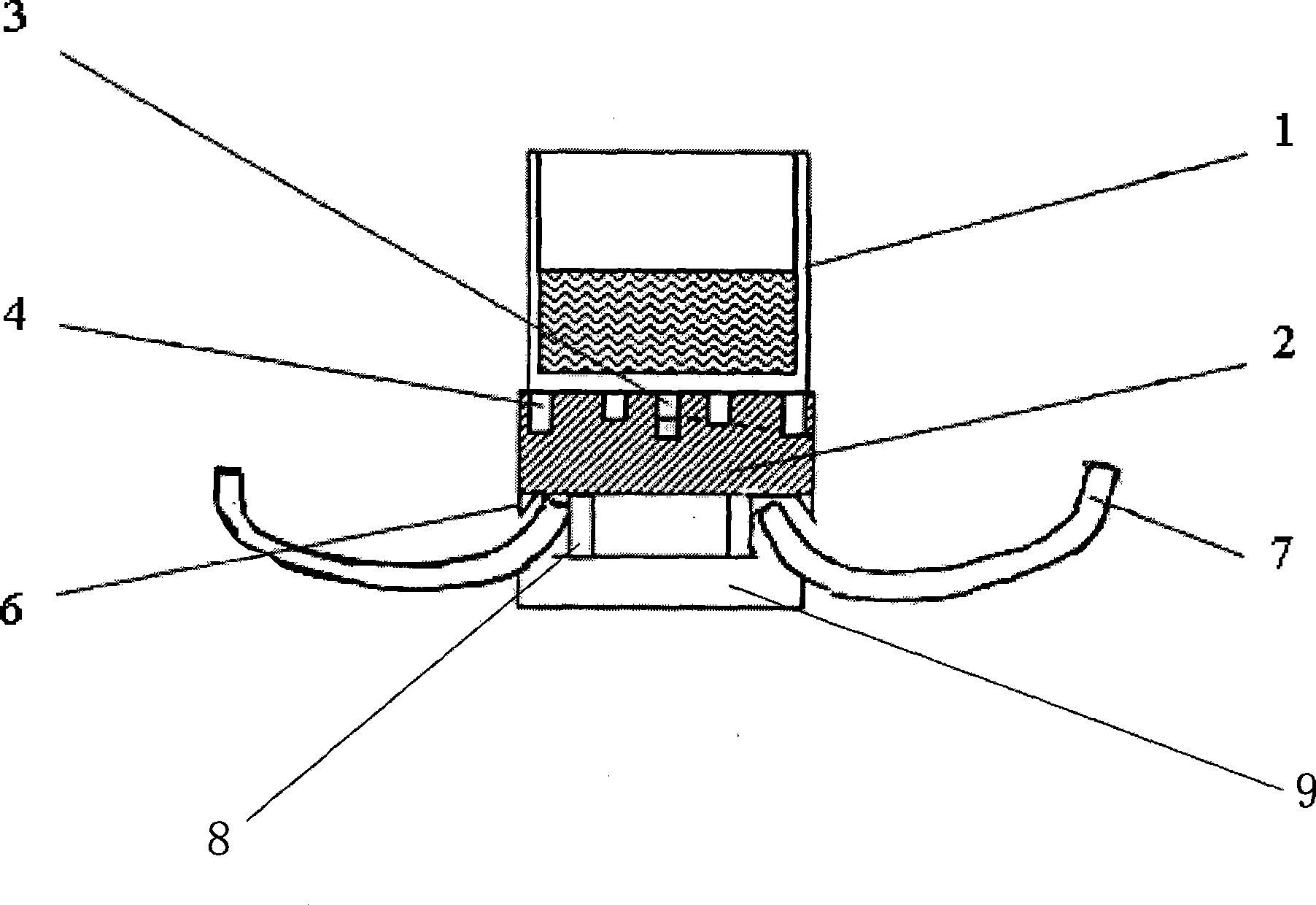

[0018] Such as figure 1 As shown, a silicon liquid leakage protection device for polysilicon purification or ingot casting furnace includes a crucible 1, a platform 2, a graphite support 8 and a stainless steel platform 9, the graphite support 8 is arranged on the stainless steel platform 9; the platform 2 is arranged on the graphite support 8 Above; the crucible 1 is set on the platform 2, the thickness of the platform is at least 50mm, and it also includes chamfers 6 and solidification grooves 7, and at least one radial guide groove 3 and at least one latitudinal guide groove are opened on the upper surface of the platform 2 4. The radial guide groove 3 diverges radially outward from the center of the platform 2; the latitudinal guide groove 4 surrounds the center of the platform 2 and is similar in shape to the periphery of the platform 2; the radial guide groove 3 and the weft guide groove 4 intersect into a network; the depth and width of the radial guide groove 3 and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com