High-precision roller-spacing control system

A control system and high-precision technology, which is applied in the field of the host pitch control system of the S-type four-roll calendering line, can solve the problems of affecting the service life of electrical components and motors, being susceptible to external interference, and losing sensors, saving raw materials and reducing Production cost, the effect of eliminating fixed hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but is not limited to specific embodiments.

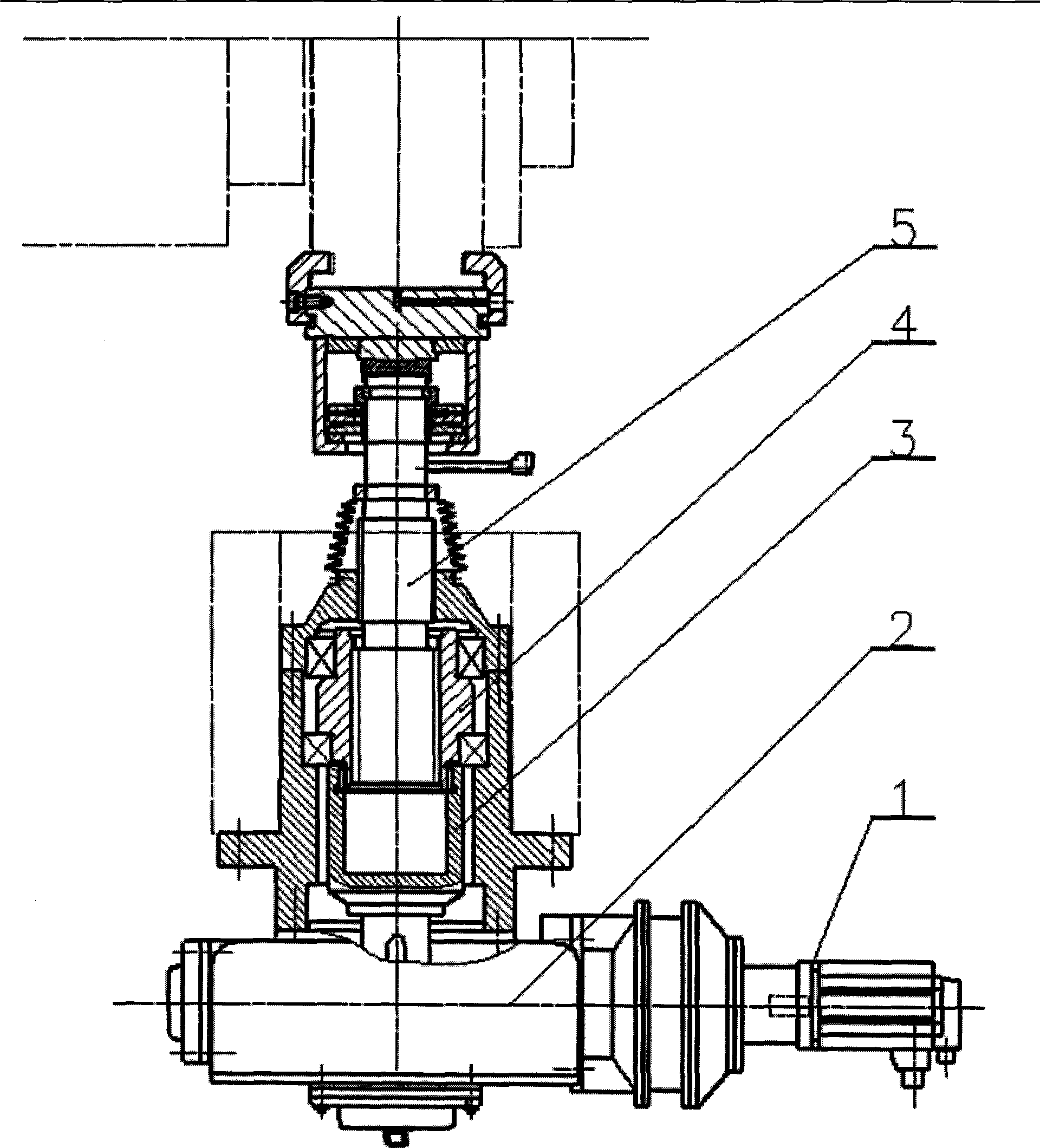

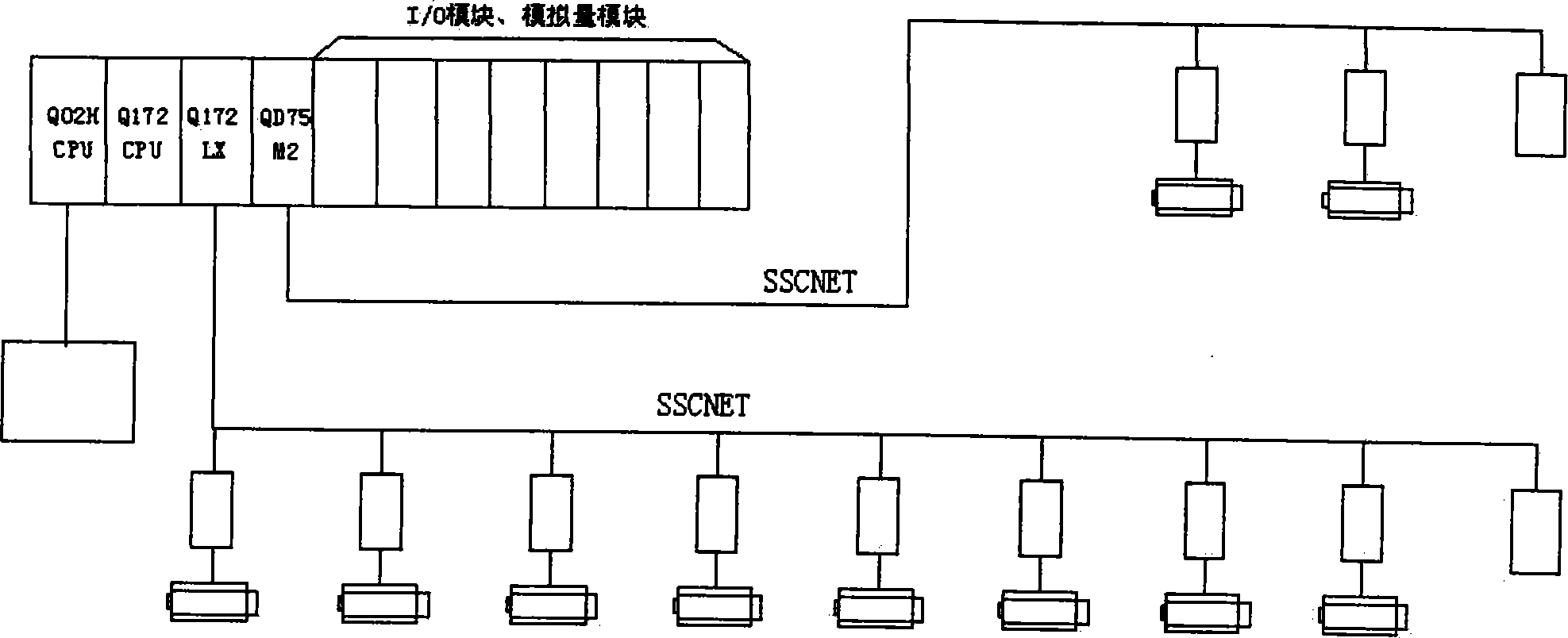

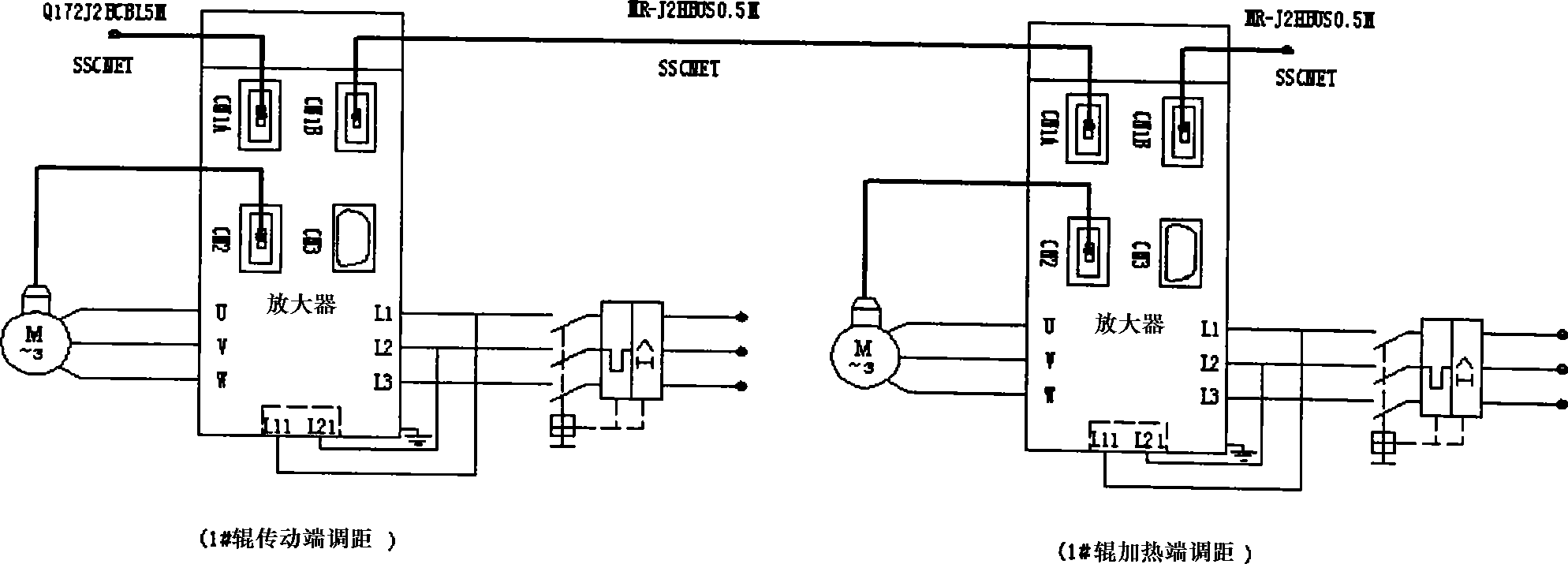

[0016] Such as figure 1 , 2 The high-precision roller distance control system shown is composed of a distance adjustment part and a control part, and the distance adjustment part is composed of a distance adjustment part and a control part. figure 1 As shown, the servo motor 1 drives the worm gear box 2 through the reduction box, the worm drives the nut 4 through the inner and outer gear sleeves 3, the screw 5 matched with the nut does not rotate, and the rotation of the nut drives the screw to move radially back and forth, and the screw is connected to the bearing body Move back and forth with the lead screw, so as to realize the distance adjustment control of the roller. The control part uses Mitsubishi’s Q series CPU, including the main controller Q02HCPU, motion controller Q172CPU, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com