Green appraising method and device in manufacture course of products

A technology of product manufacturing and evaluation methods, applied in the field of product manufacturing, can solve problems such as inability to meet, analyze, and unable to make corresponding evaluations of resource and environmental conditions, and achieve the effect of reducing negative environmental impacts and improving utilization rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: Embodiment 1 of the present invention provides a kind of green evaluation method of product manufacturing process, such as figure 1 Shown is a schematic flow chart of the method provided in this embodiment 1, the method comprising:

[0037] Step 11: Establish a green feature database for product processing technology.

[0038] Specifically, when evaluating the greenness of a product’s manufacturing process, it is necessary to first establish a database of green characteristics of the product’s processing technology; the database includes: 1) resource and environmental attribute indicators generated during the product’s manufacturing process; 2. ) the index value corresponding to the resource environment attribute index; 3) the quantification rule of the resource environment attribute index value.

[0039] The resource and environment attribute index values mentioned above specifically include the consumption attribute values of raw materials, auxiliar...

Embodiment 2

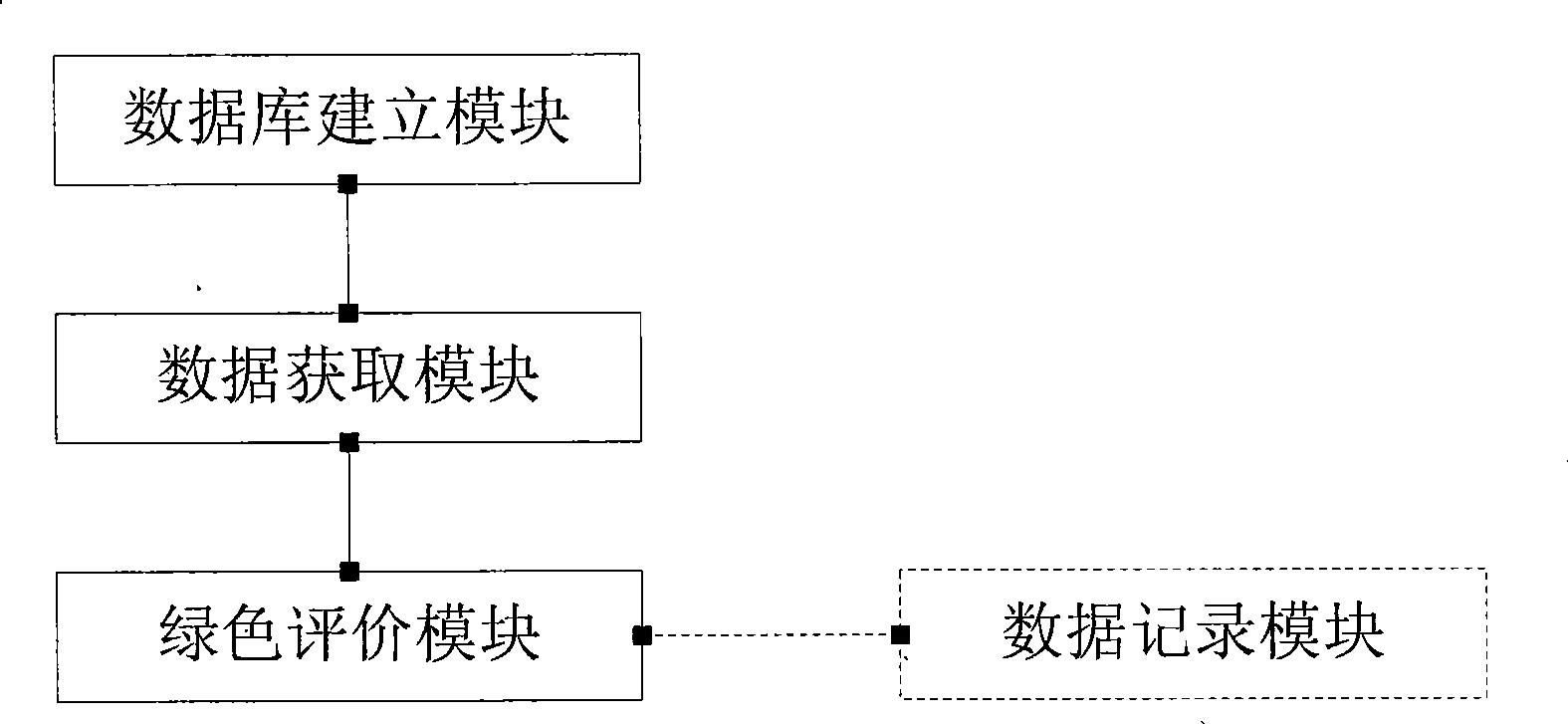

[0075] Embodiment 2: Embodiment 2 of the present invention provides a green evaluation device in the product manufacturing process, such as figure 2 Shown is a schematic structural diagram of the device provided in Embodiment 2, the device includes a database building module, a data acquisition module and a green evaluation module, wherein:

[0076] The database establishment module is used to establish a processing technology green feature database for products, and the database includes the resource environment attribute index generated in the product manufacturing process and the index value corresponding to the resource environment attribute index, and the resource environment attribute index. Quantification rules for environmental attribute index values;

[0077] The data acquisition module is used to acquire the resource and environment attribute index value generated in the manufacturing process of the product from the database when the product needs to be green evalua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com