Wind-powered turntable bearing combination property bench

A slewing bearing, comprehensive performance technology, applied in the direction of mechanical bearing testing, etc., to achieve the effect of compact structure and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

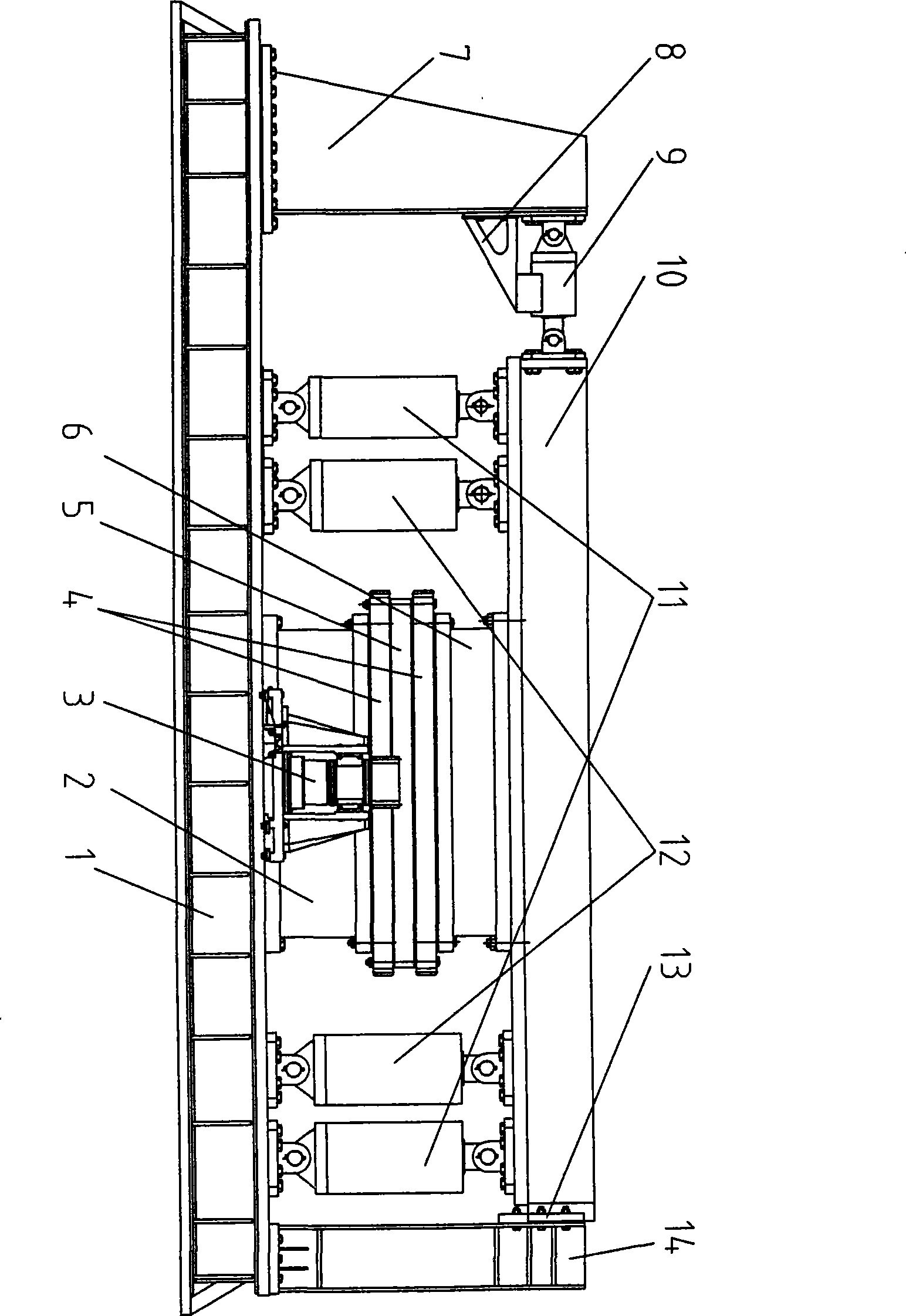

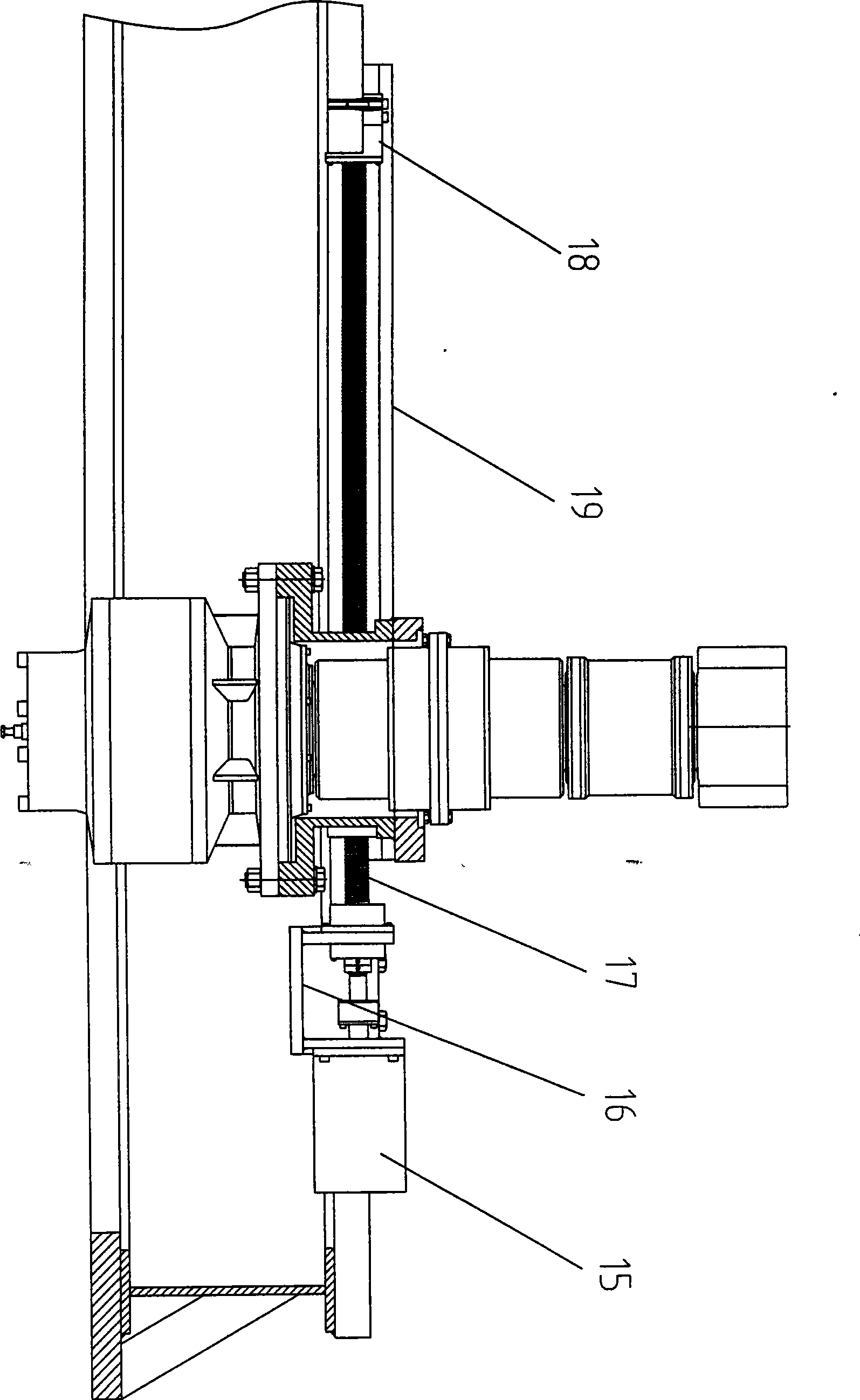

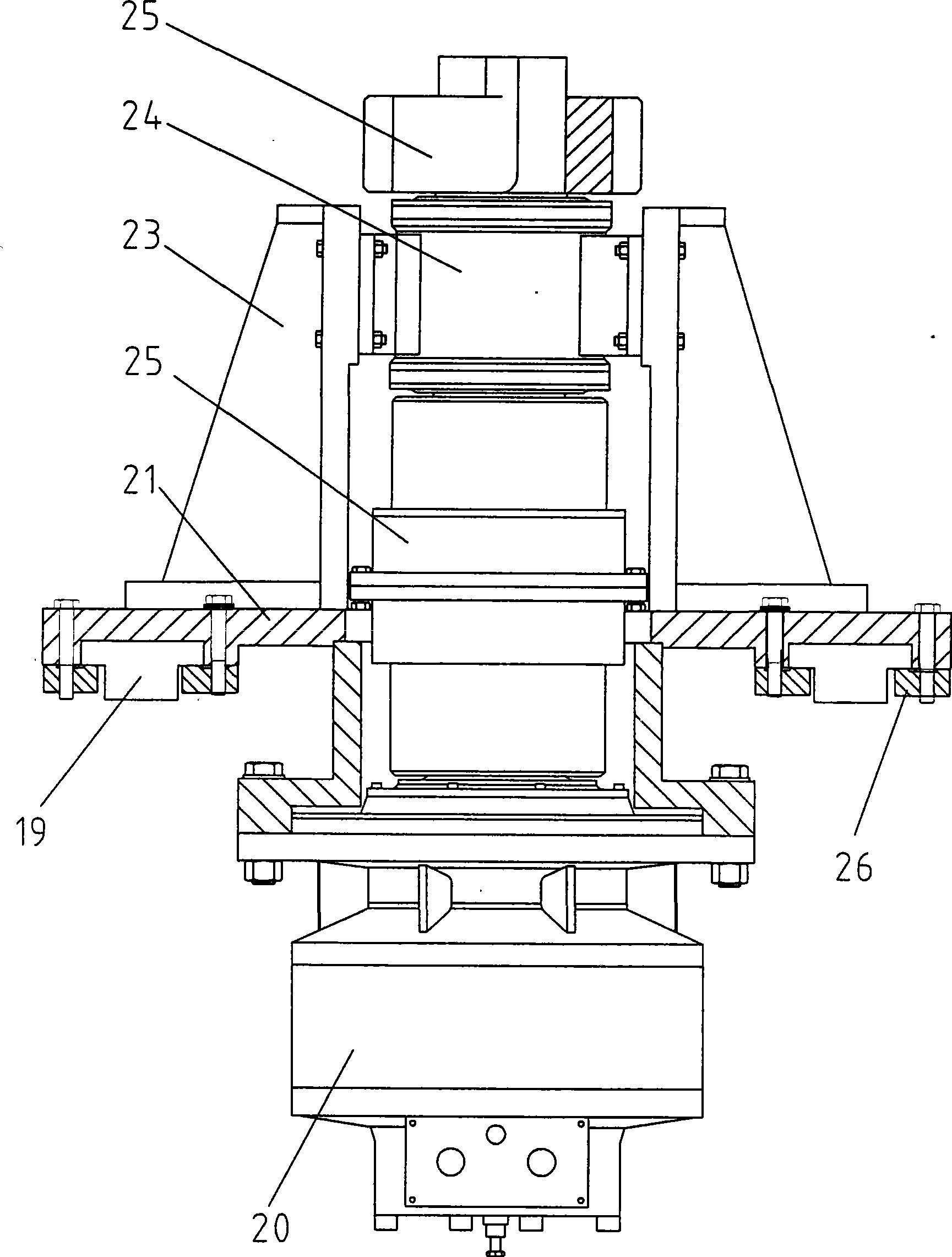

[0022] A comprehensive performance test bench for wind power turntable bearings, including a bottom plate 1, a lower transfer flange 2, a power assembly 3, a wind power turntable bearing 4, an upper transfer flange 6 and a loading cover 10, the bottom plate 1 is connected by bolts to the bottom Connect the flange barrel 2, connect the wind turbine turntable bearing 4 with bolts on the bottom adapter flange barrel 2, connect a pair of wind turbine turntable bearings 4 on the bottom adapter flange barrel 2, and adopt the "back-to-back" installation method for two sets of the same specification The wind power turntable bearing 4; the power assembly 3 is provided with a pinion 25, and the pinion 25 meshes with the inner ring or the outer ring transmission gear of one wind power turntable bearing 4 in a pair of wind power turntable bearings 4; the upper bolt of the wind power tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com