Four-side connecting open circle hole combined steel sheet shear wall

A steel plate shear wall and connecting plate technology, applied to walls, building components, earthquake resistance, etc., can solve the problems of inability to guarantee the anti-yield energy consumption effect of combined steel plate walls, and achieve improved ductility and comprehensive energy dissipation performance, good energy consumption effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

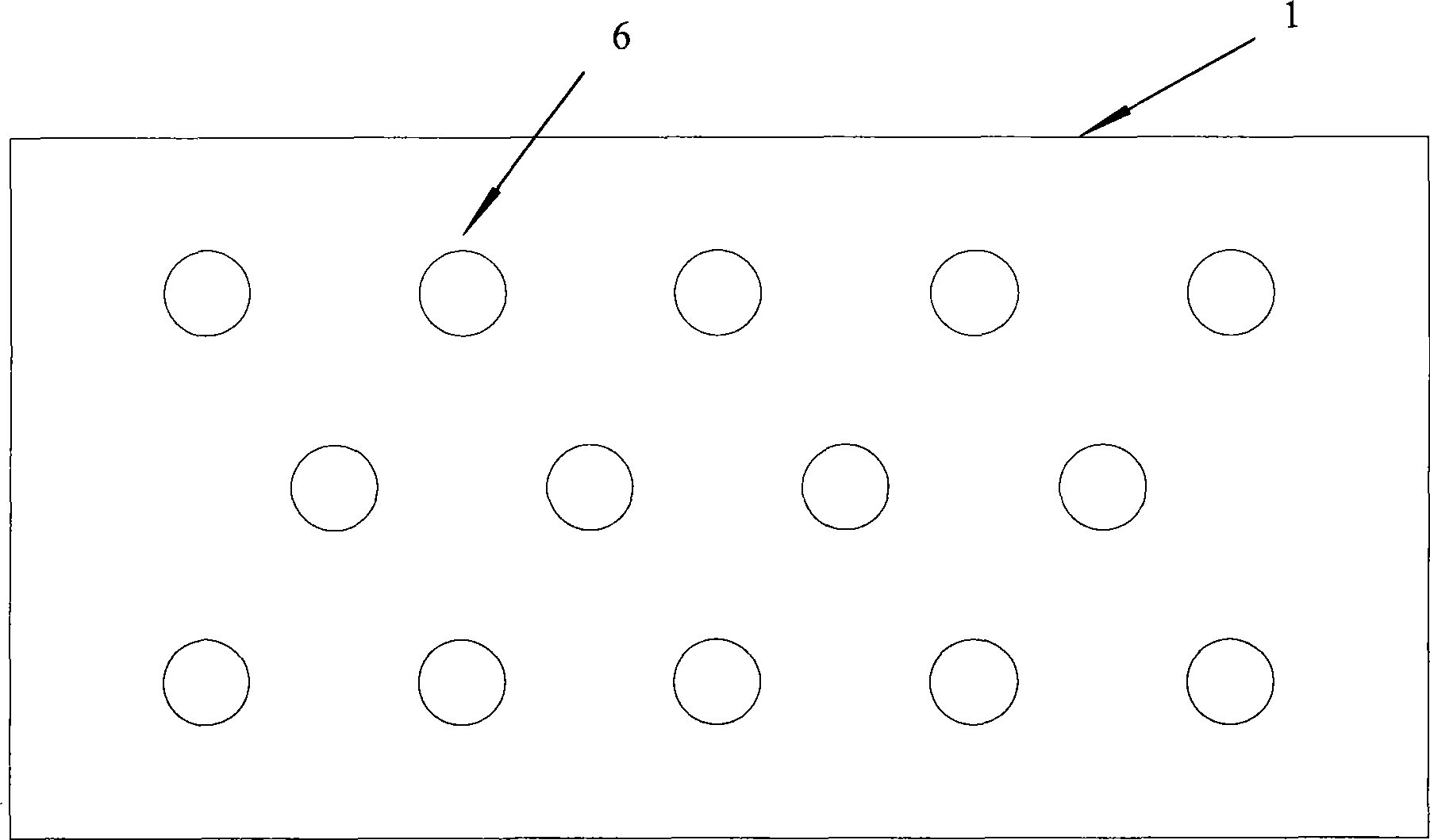

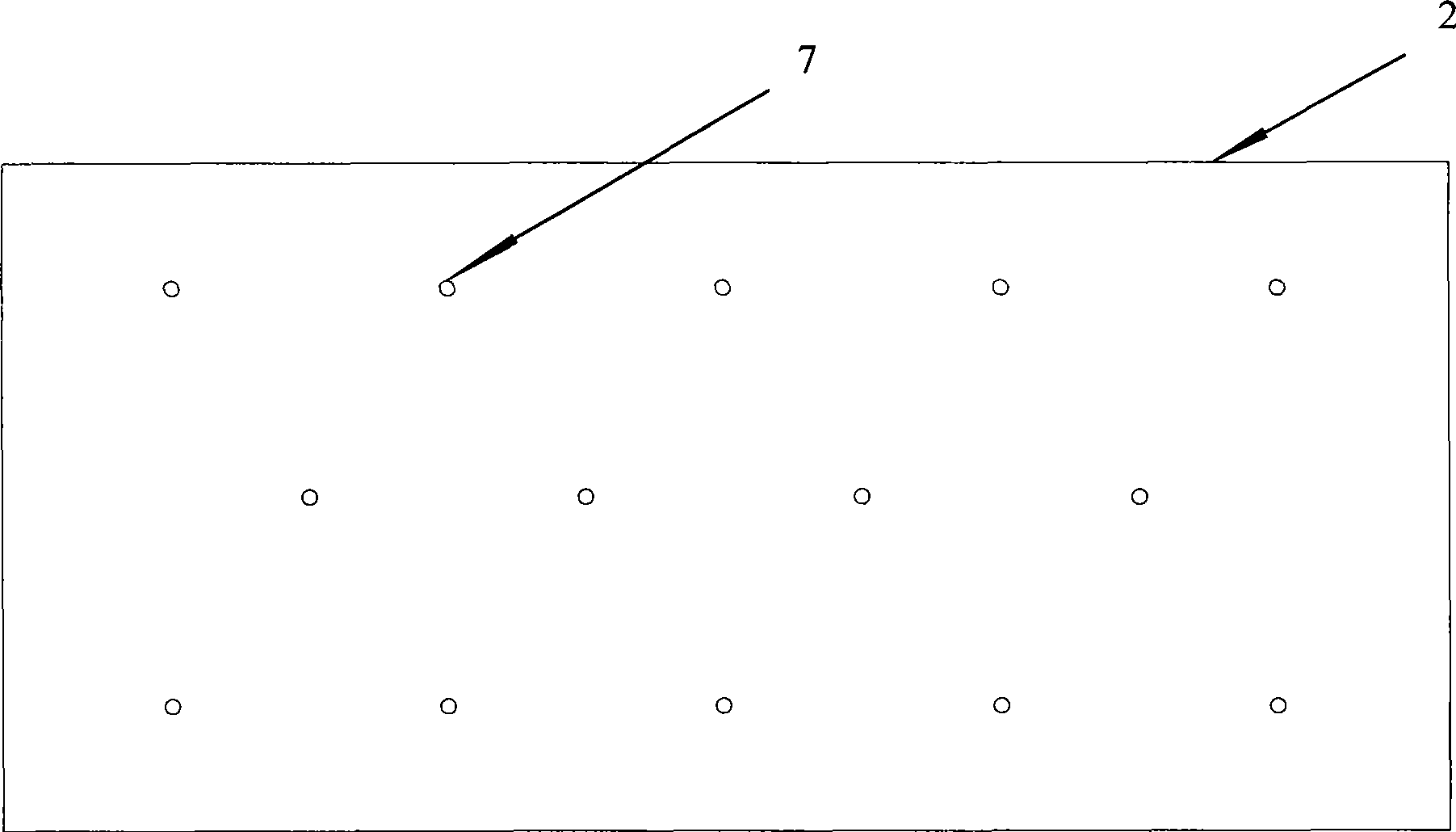

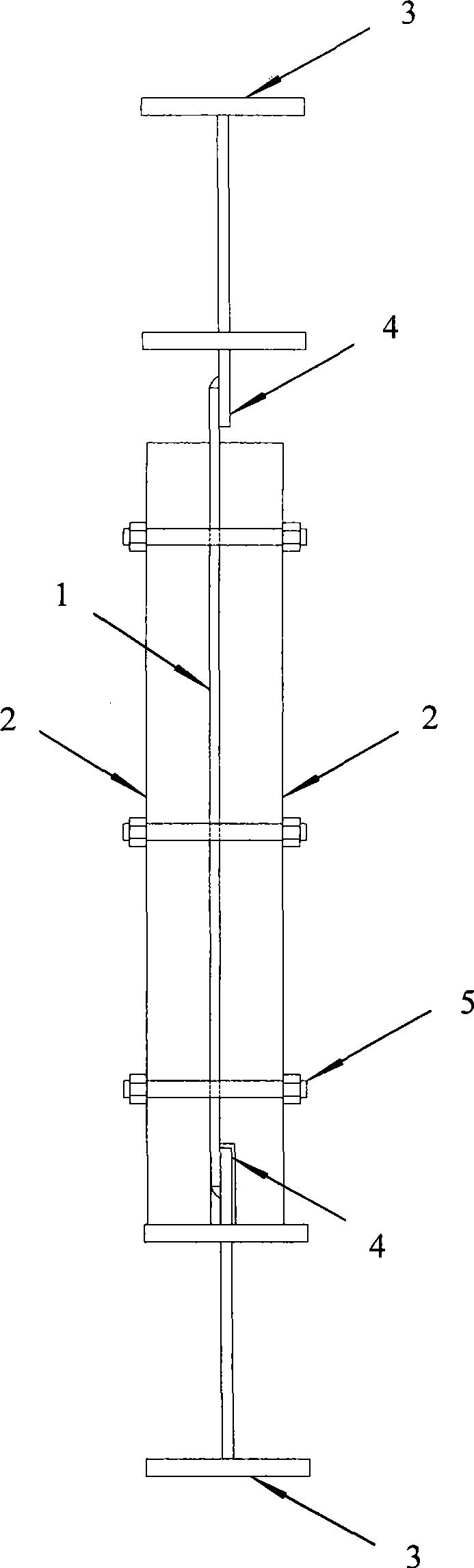

[0025] Embodiment 1: as figure 1 — image 3 Shown, the composite steel plate shear wall with four sides connected with round holes of the present invention is made up of inner filling steel plate 1, prefabricated concrete plate 2, frame structure member 3, connecting plate 4; the structure of inner filling steel plate 1 is as follows figure 1 As shown, there are larger circular holes 6 on the inner filling steel plate 1, and the openings are concentrated in the middle of the inner filling steel plate 1 as much as possible. Taking this example as an example, the distance between the centers of the circular holes 6 can be set to 3 times. The diameter of the circular hole, under the premise of ensuring the opening area, the circular hole 6 is concentrated in the middle of the inner filling steel plate 1 as far as possible, so that the distance between the edge circular hole 6 and the edge of the inner filling steel plate 1 is the largest, and the total area of the circular hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com