Roller transmission mechanism for drafting assembly of spinning frame

A drafting device and transmission mechanism technology, applied to spinning machines, drafting equipment, spinning machines with continuous winding, etc., can solve the problems of increasing material consumption, reducing slippery rate, increasing mechanical transmission load, etc., and achieve reduction Effects of material consumption, improvement of yarn quality, and reduction of frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

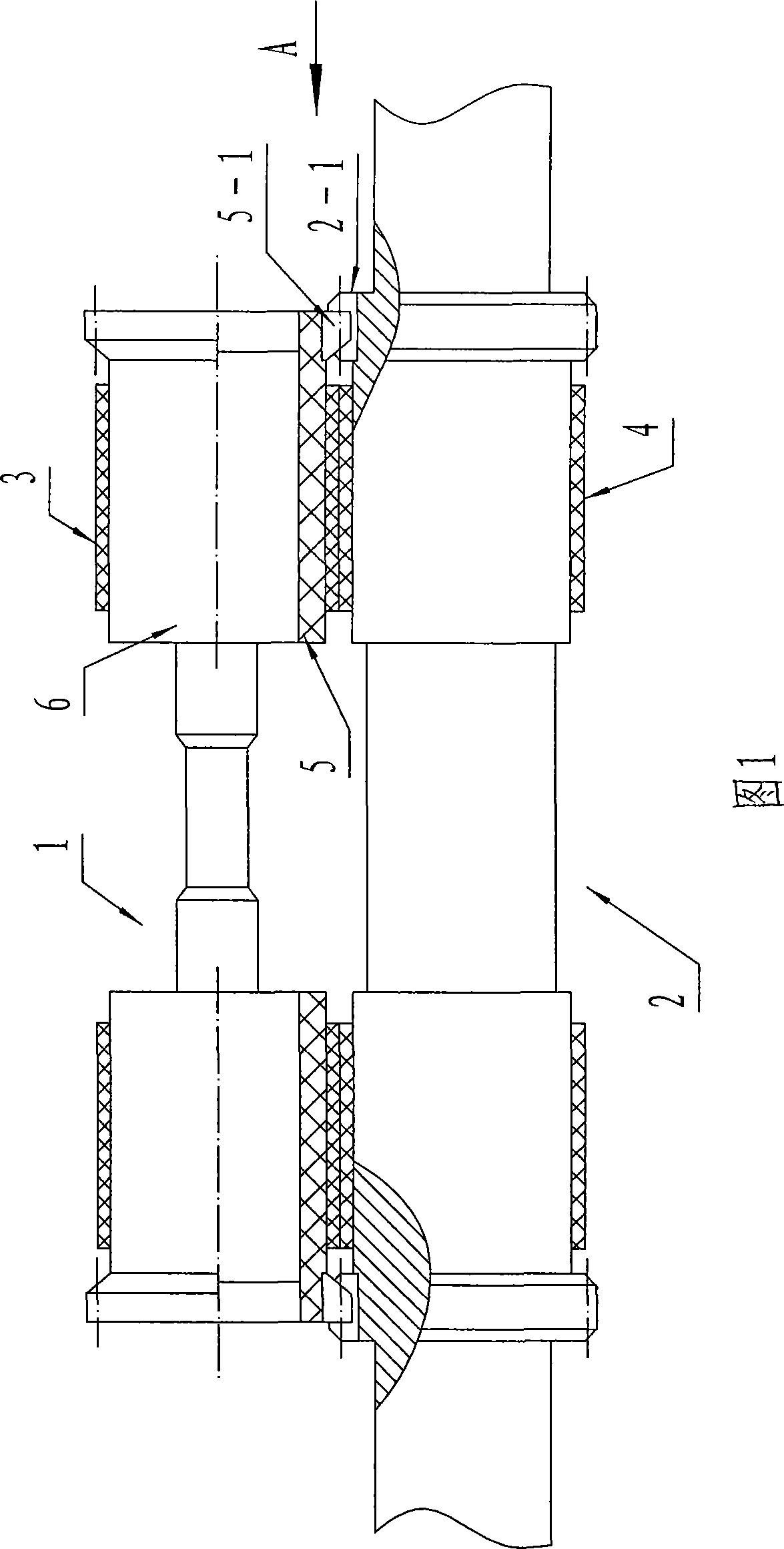

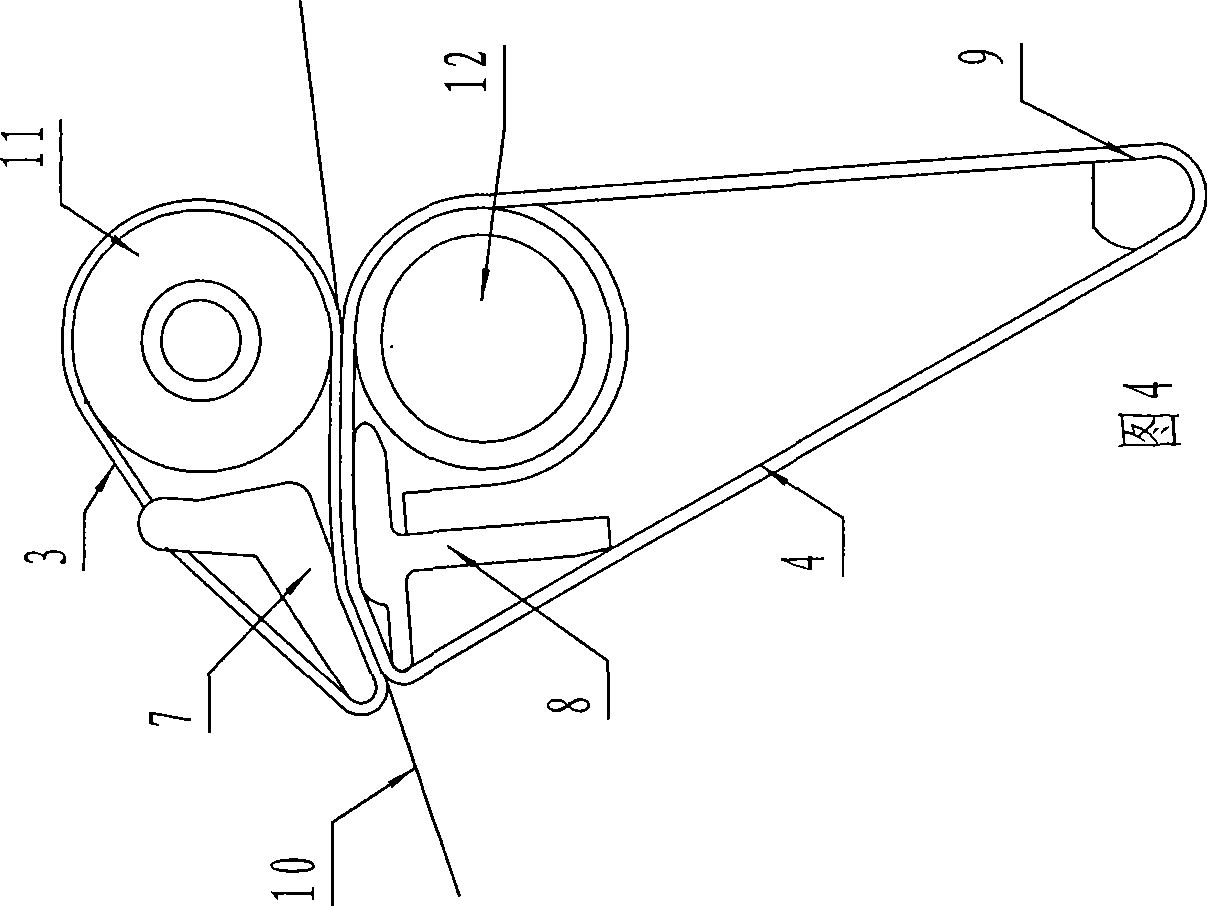

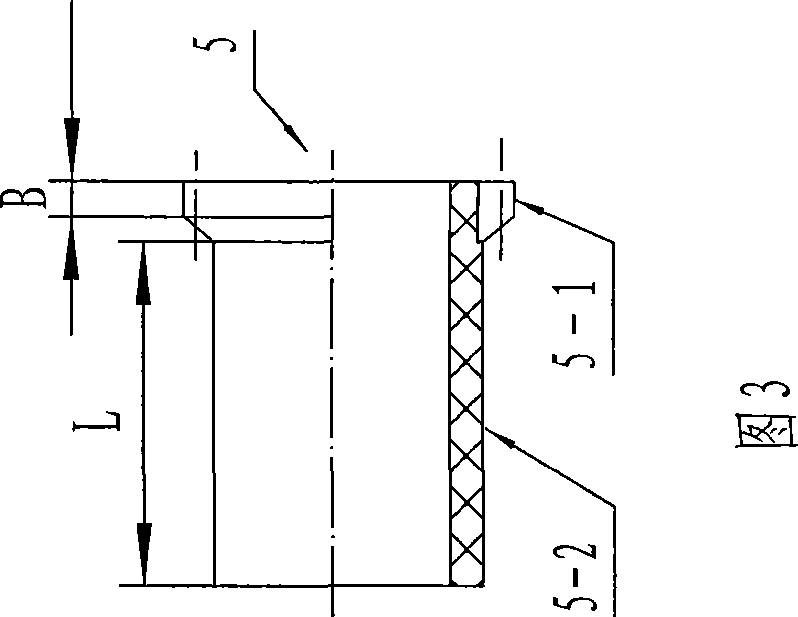

[0016] The invention improves the roller transmission mechanism of the drafting device aiming at the root cause of the slippery rate of the apron. Referring to Fig. 1 and Fig. 2, the composition of the present invention includes the lower middle roller 2 of the driving element, the upper middle roller 1 of the driven element, and the upper apron 3 and the lower apron 4 positioned on the upper and lower middle rollers. A pair of gears with the same number of teeth forms a transmission connection between the upper middle roller and the lower middle roller. Among them, the driving gear 2-1 with an integrated structure is cut out on the lower middle roller; the upper middle roller is composed of a rubber roller bearing 6 and a gear sleeve 5 with an interference fit with it. This structure is beneficial to the maintenance and replacement of the driven gear, and can improve The coefficient of friction between the gear sleeve and the upper rubber ring. Referring to Fig. 3, the gear ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Tooth width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com