Paper feeding device of automatic paper folding machine

A technology of origami machine and paper feeding, applied in the field of origami machinery, can solve problems such as unsmoothness and low efficiency of origami, and achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

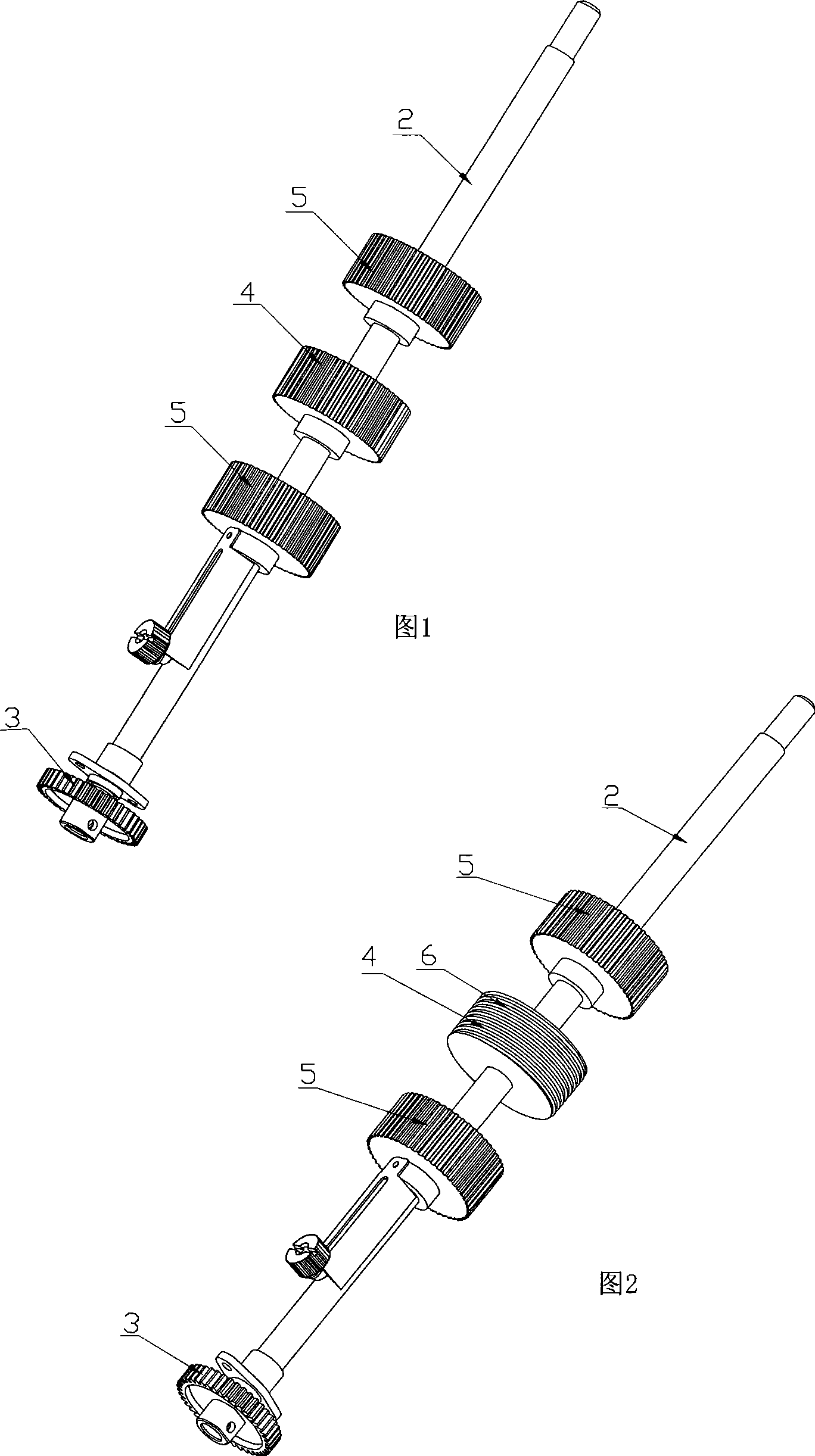

[0016] Fig. 1 is the schematic diagram of the paper pickup rolling assembly of existing automatic paper folding machine; 1 Installed in front of the pickup roller assembly, it is used to place the paper that needs to be folded. The paper ejector 7 is installed in the middle of the bottom plate of the paper inlet behind the bottom of the pickup roller assembly. The pickup roller assembly includes: The rolling shaft 2, the driving gear 3 installed on one end of the rolling shaft 2, the main pickup roller 4 installed in the middle of the rolling shaft 2, the bottom of the main pickup roller 4 is opposite to the paper ejector 7, installed on the rolling shaft 2 and connected to the main pickup The left and right sub-pickup rollers 5 spaced apart from each other.

[0017] The paper feeding device of the automatic paper folding machine of the present inve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com