Automatic original-glass fetching manipulator of automobile glass pre-treatment production line

An automotive glass and pretreatment technology, which is applied to manipulators, program-controlled manipulators, conveyor objects, etc., can solve the problems of complex programming, high maintenance costs, and high costs, and achieve the effect of extending the work cycle and reducing work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

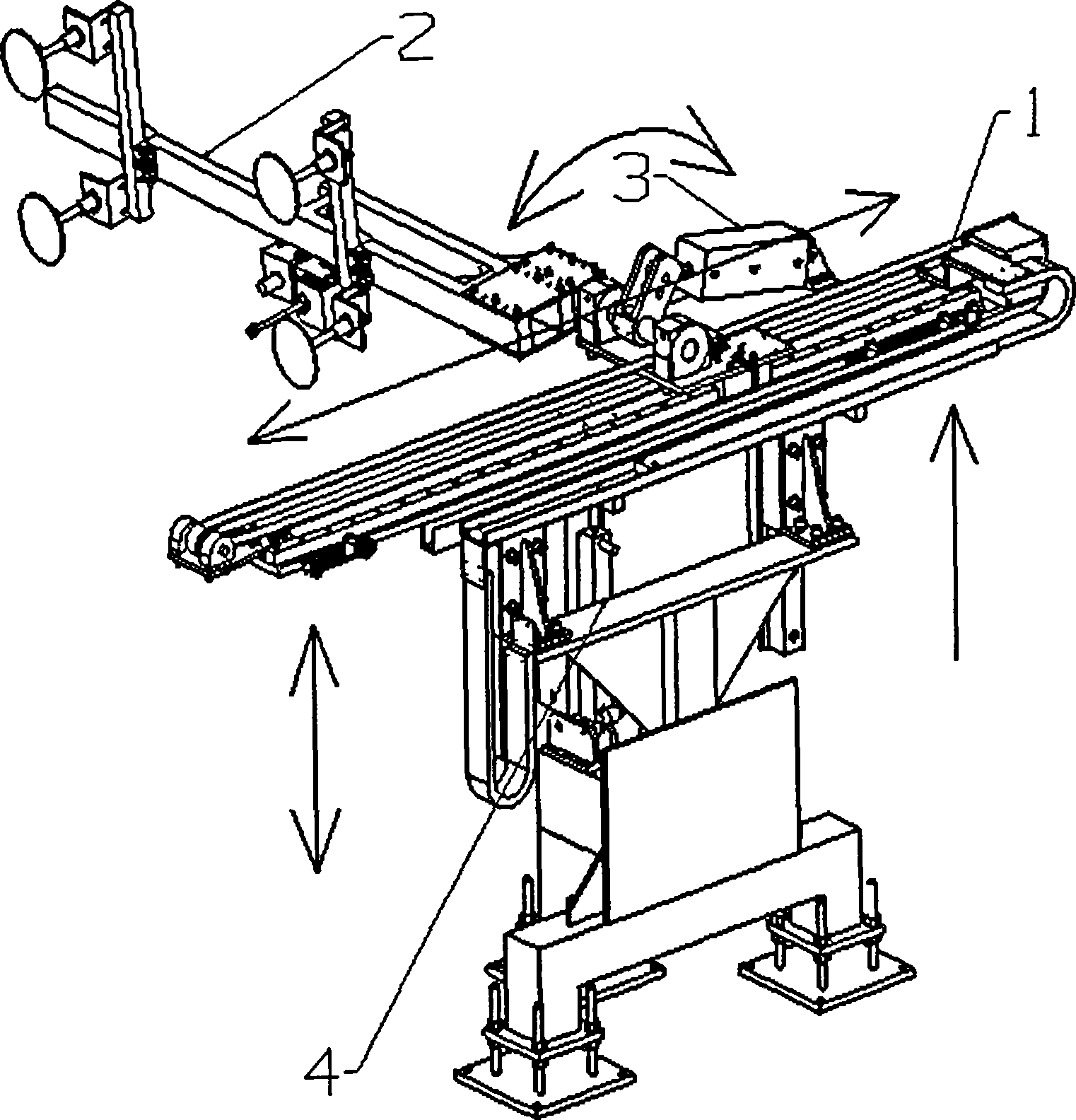

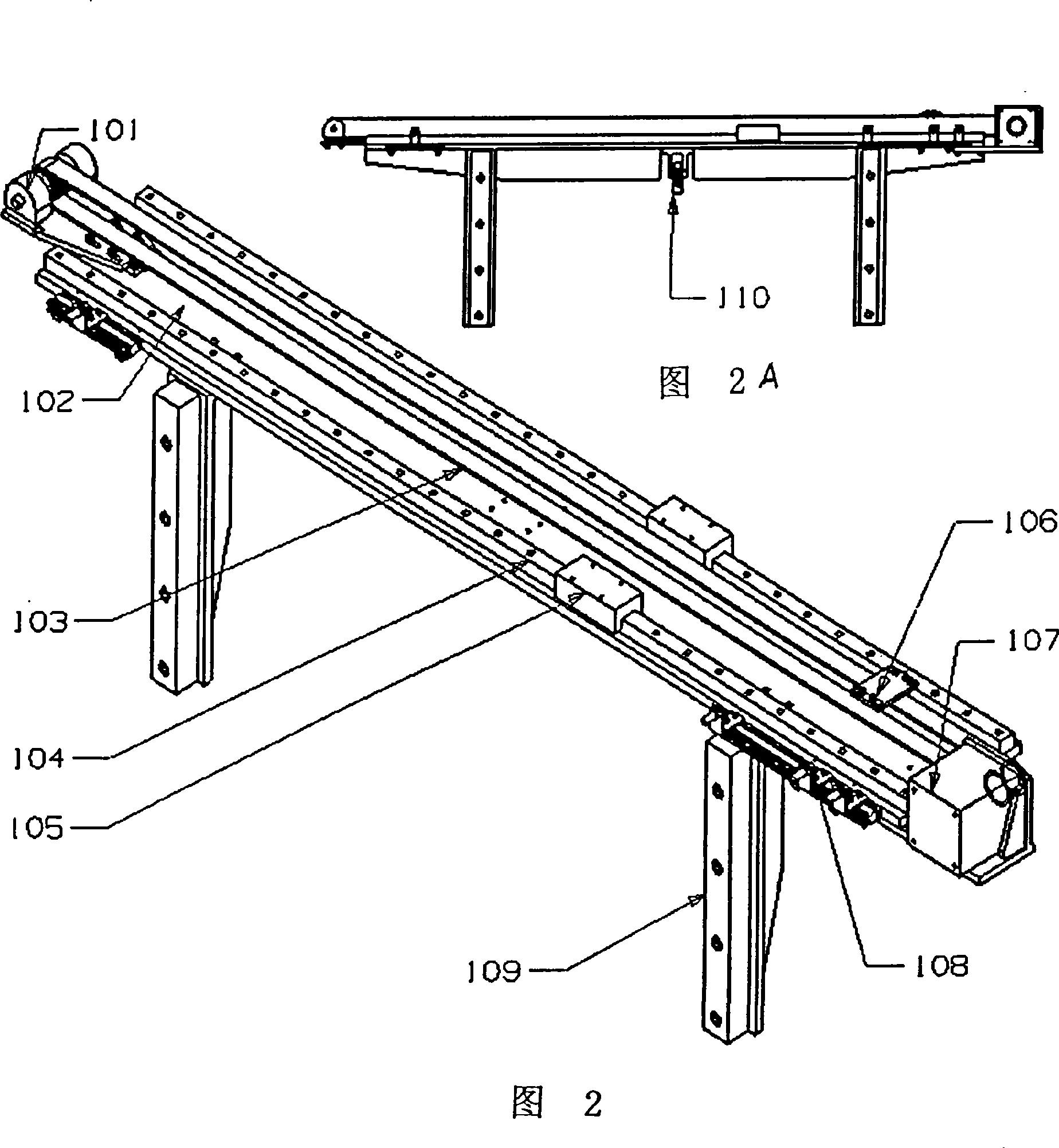

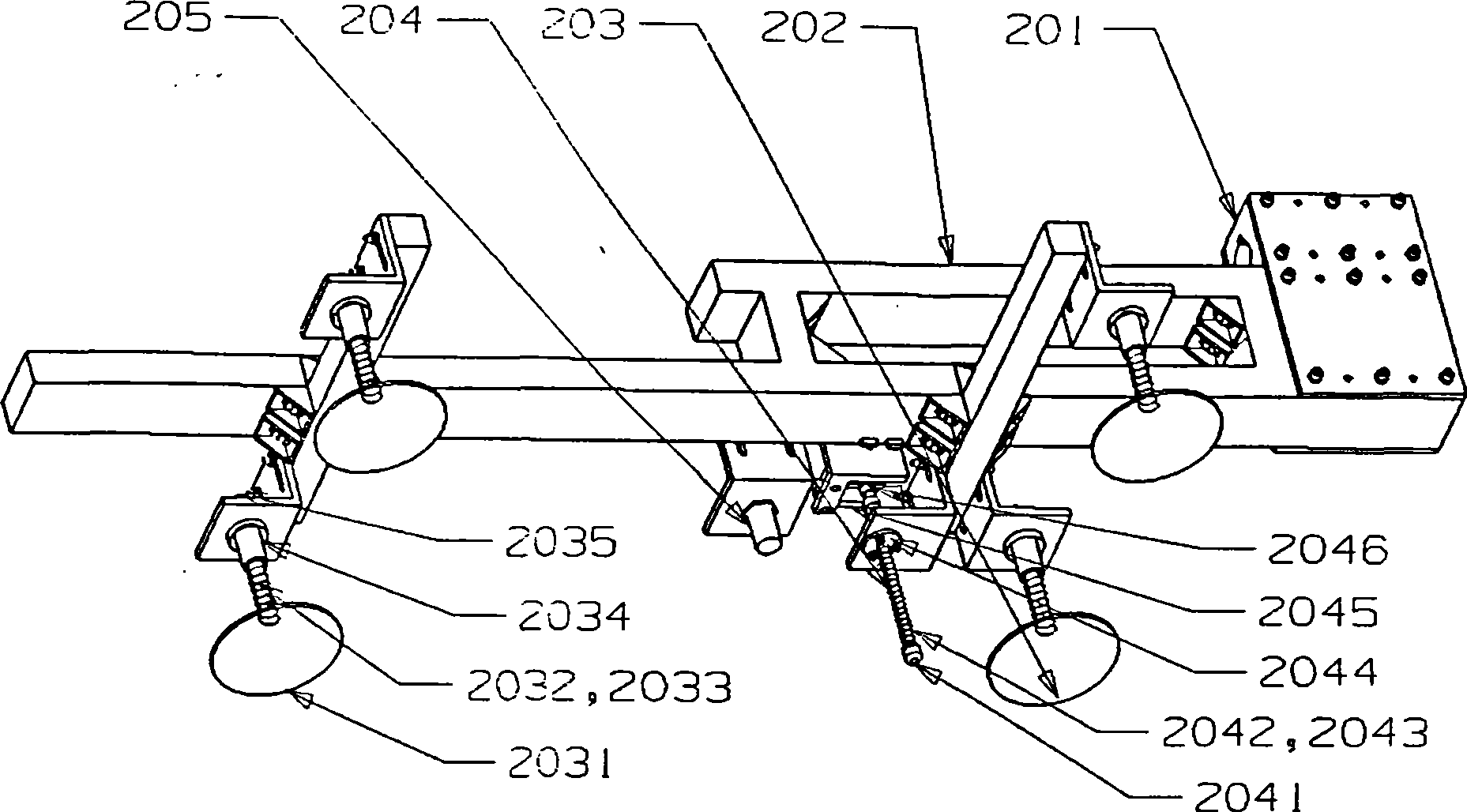

[0047] figure 1 Be the three-dimensional structural diagram of the present invention, rise and fall buffer mechanism 4 (as Figure 5 Shown) is an automatic film-loading mechanical mobile phone stand, the stand is made up of three three-legged single-leg frames 401, a transmission mechanism platform 1 is installed on the top of the support mechanism, and two Z The axial ascending and descending linear guide rail 104 is inserted into the two cushioning mechanism linear sliders 406 installed on the upper two wings of the machine base, and the transmission mechanism platform ascending and descending cylinder 403 and the transmission mechanism platform auxiliary ascending and buffering descending cylinder 404 (two cylinders connected in parallel) pass through the cylinder The connecting base 110 and the cylinder connecting base 402 are connected to the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com