Single-plastid vibration crusher

A crusher, single-body technology, applied in non-rotational vibration suppression, grain processing, etc., can solve the problems of low material crushing ratio, high noise, and high bearing damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

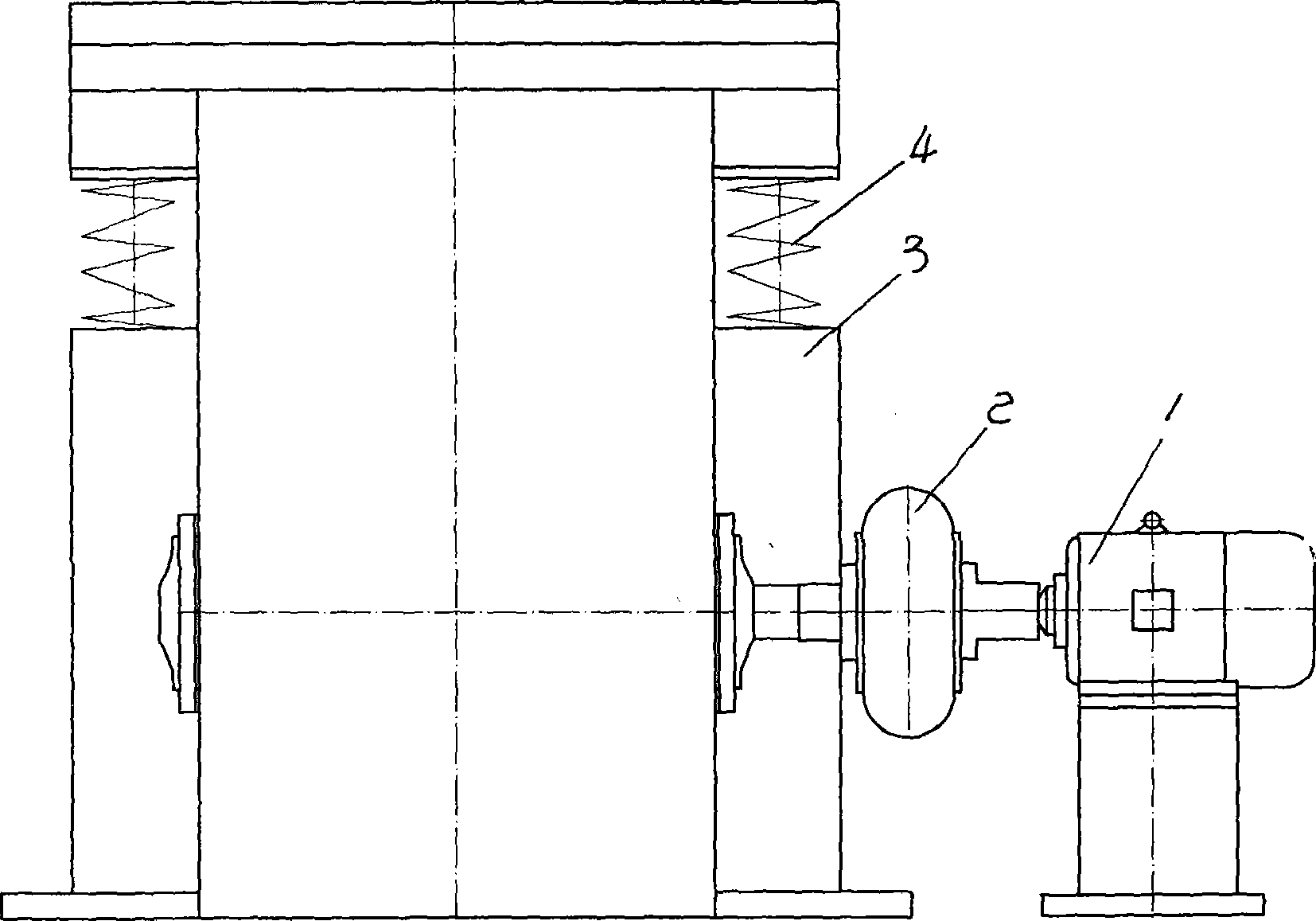

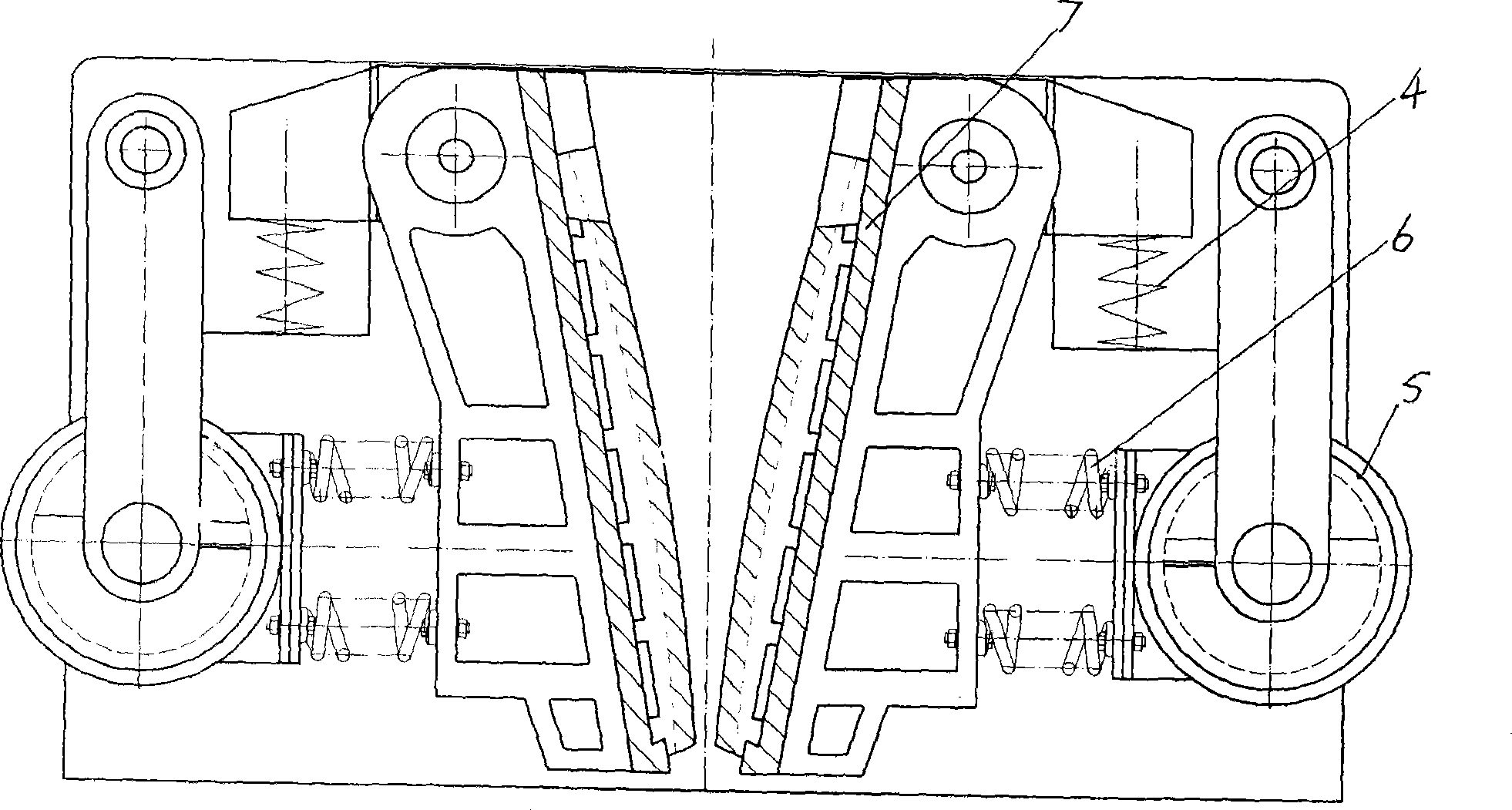

[0005] The present invention will be described in detail in conjunction with the above-mentioned drawings. The upper ends of the two opposite jaw plates 7 are hinged to the body 3 through eccentric pins, and the motor is connected to the exciter 5 through a flexible coupling 2. Between the exciter and the body A damping spring 4 is arranged between them, and a spring 6 is respectively arranged between the left and right two relative jaw plates and the vibrator.

[0006] The crushing principle of the present invention is that the left and right jaw plates form a conical cavity with a large top and a small bottom, the upper port is the feed port of the crusher, and the lower port is the discharge port. When crushing, start two motors 1 (reverse rotation), and the horizontal exciting force generated by the exciter will make the left and right jaws slap in the opposite direction through the spring 6. The frequency can be determined according to the characteristics of the material. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com