Sewage water source heat pump system

A sewage source heat pump and sewage source technology, which is applied in heat pumps, clean heat transfer devices, lighting and heating equipment, etc., can solve the problems that the evaporator or condenser cannot be used, cannot work stably for a long time, and the efficiency of the system unit decreases, etc., to achieve Ensure long-term effective operation, ensure good performance and service life, and improve the effect of decontamination ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

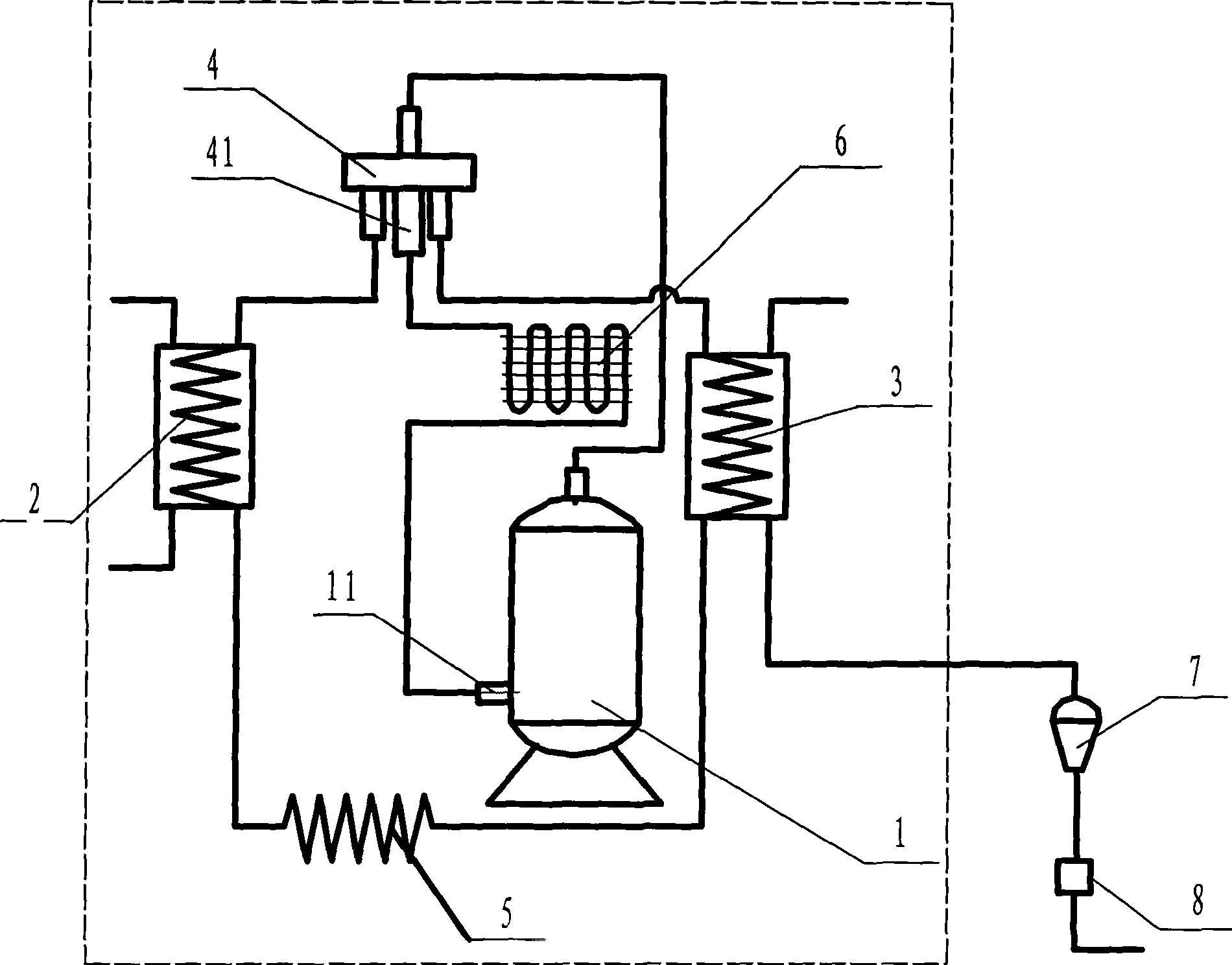

[0023] Such as figure 1 Shown:

[0024] The system of the present invention includes basic components such as a compressor 1 , a condenser 2 , an evaporator 3 , a reversing valve 4 , and an expansion valve 5 in an existing traditional heat pump system. In the system, an auxiliary evaporator 6 is connected in series between the suction port 11 of the compressor and the low-pressure air return port 41 of the reversing valve; a filter purification device 7 and a dosing (deflocculating agent) device 8 are connected in series in front of the evaporator; device or evaporator as figure 2 Sewage source heat exchanger shown.

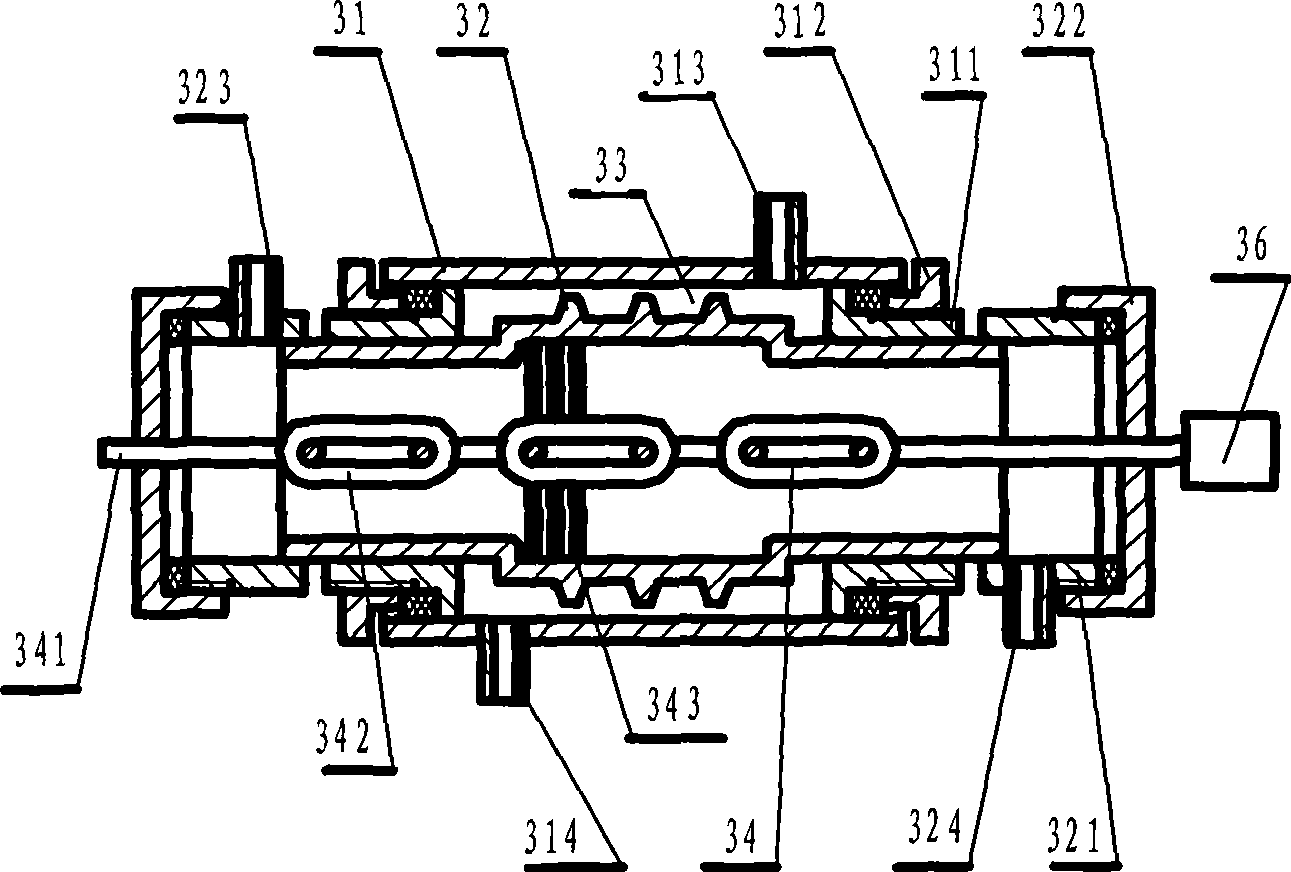

[0025] another example figure 2 Shown:

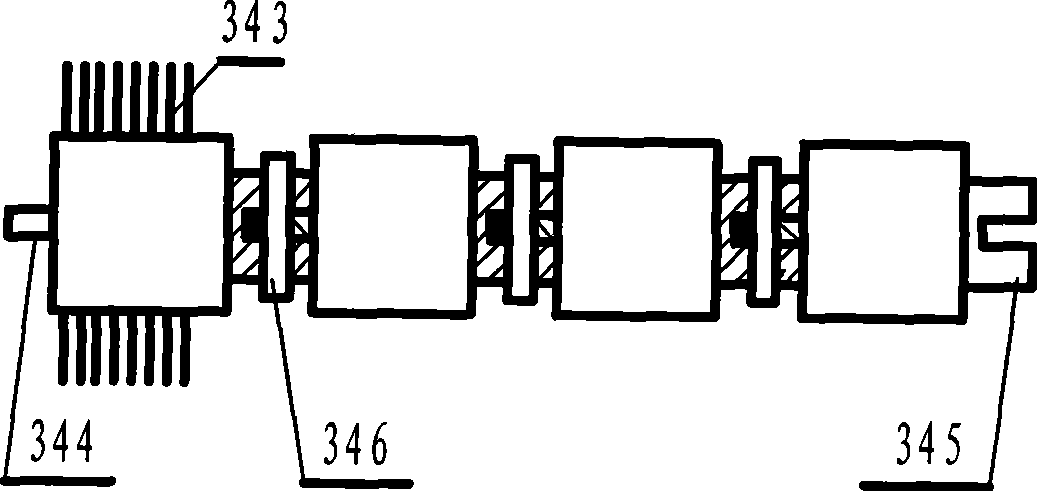

[0026] The system of the present invention is a sewage source heat exchanger with condensation or evaporation function, including a casing 31 and a heat exchange tube 32 running through it, and a circulation channel 33 for a heated medium between the inner wall of the casing and the outer wall of the heat exchange tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com