Fork mechanism of stacker

A technology of stacker and pallet fork, which is applied in the direction of lifting device, etc., can solve the problems of large size, high cost and high price, and achieve the effect of simple structure, cost saving and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

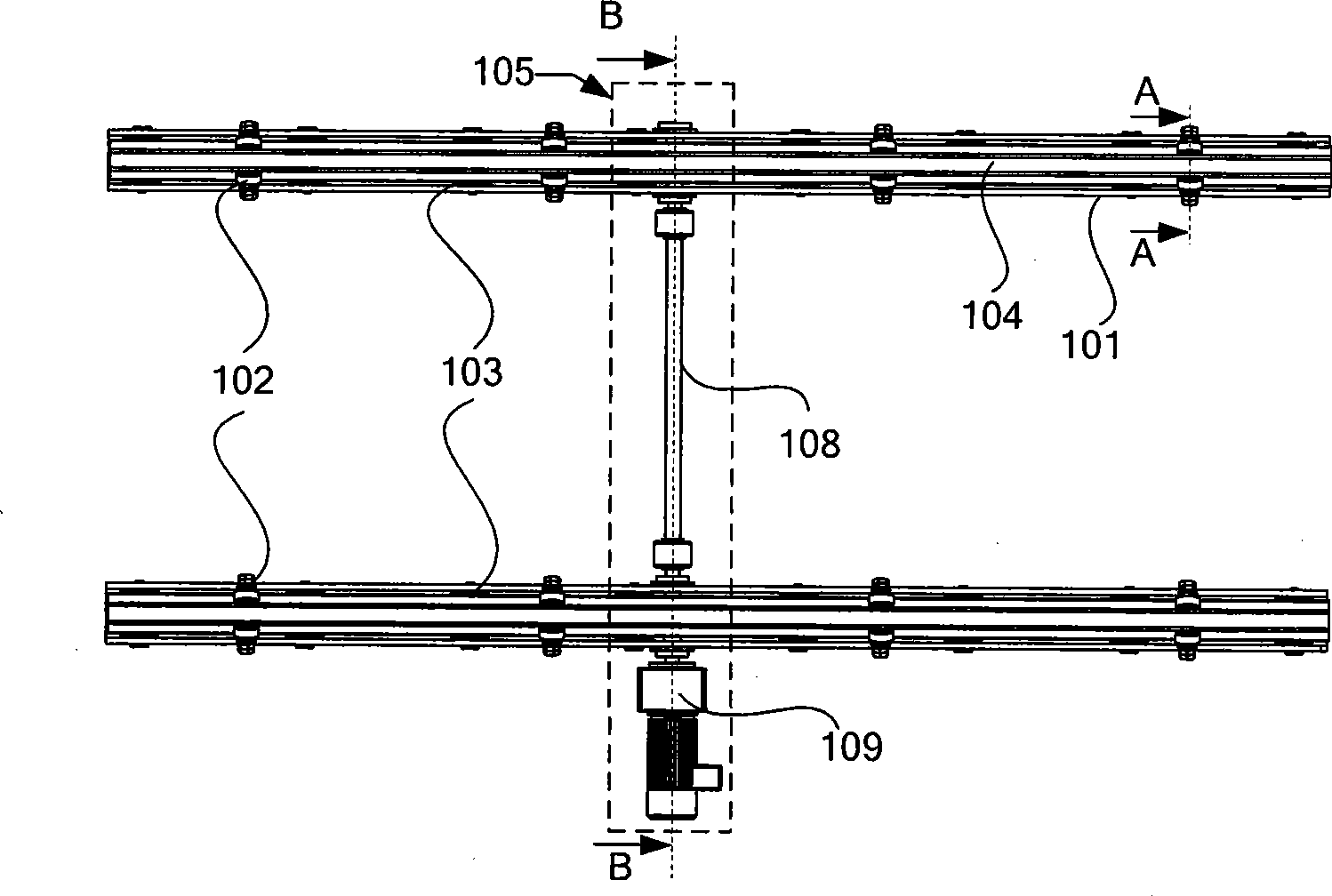

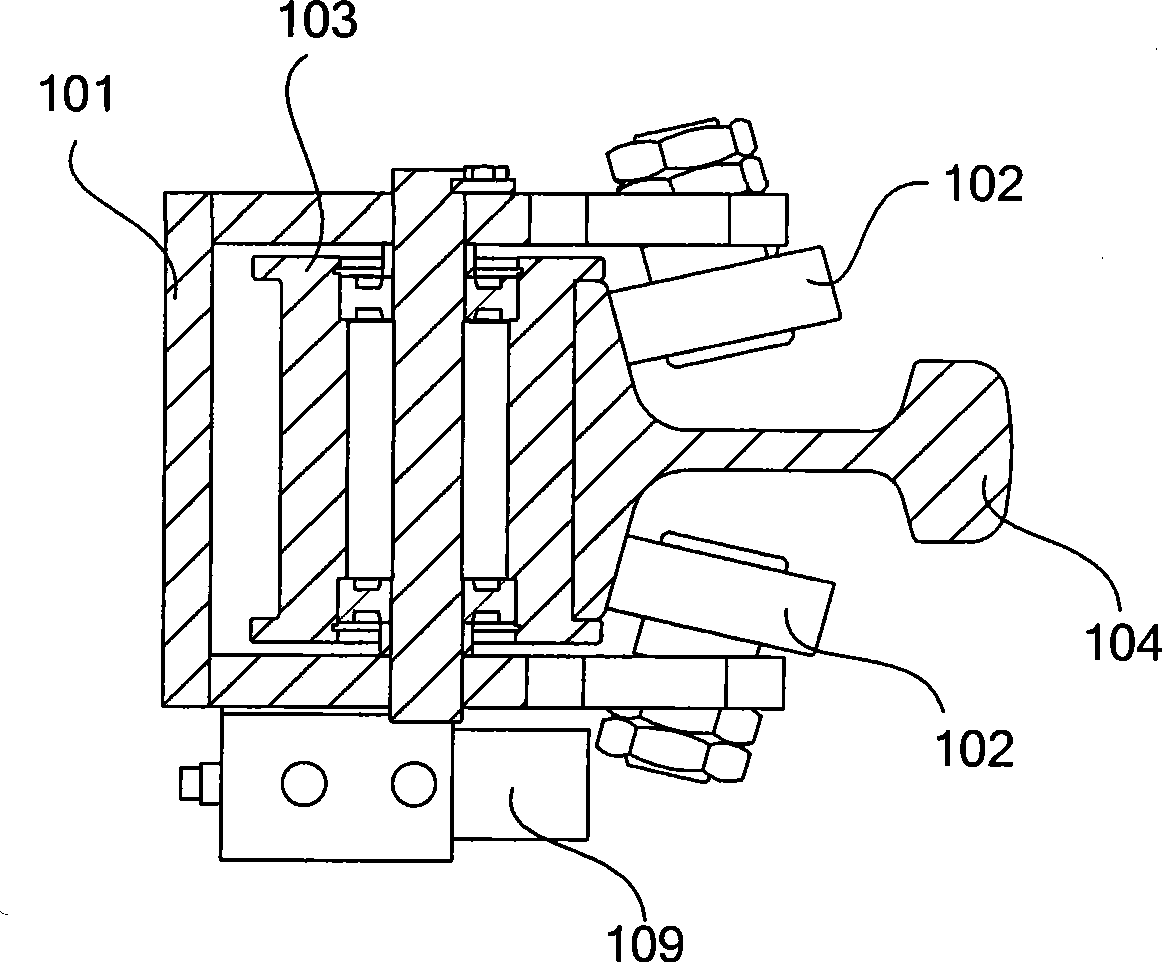

[0043] The stacker fork mechanism of the present invention will be further described in detail in conjunction with the accompanying drawings.

[0044] The invention provides a pallet fork mechanism of a stacker, which is used for accessing bogies on train sets in an automated three-dimensional warehouse.

[0045] The stacker fork mechanism of the present invention comprises a load-bearing mechanism 1 and a fork mechanism 6, such as figure 1 , the load-bearing mechanism 1 and the fork mechanism 6 are respectively connected with the crossbeam 5 on the stacker loading platform through bolt pairs. The load-bearing mechanism 1 is used to bear the vertical load of the bogie, and the fork mechanism 6 is located between the two load-bearing rails 104 of the load-bearing mechanism 1, and is used to pull the movement of the bogie and realize the access of the bogie. Its working principle is as follows: after the load-bearing rail 104 on the cargo platform of the stacker is accurately d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com