Device and process for generating biogas from organic materials

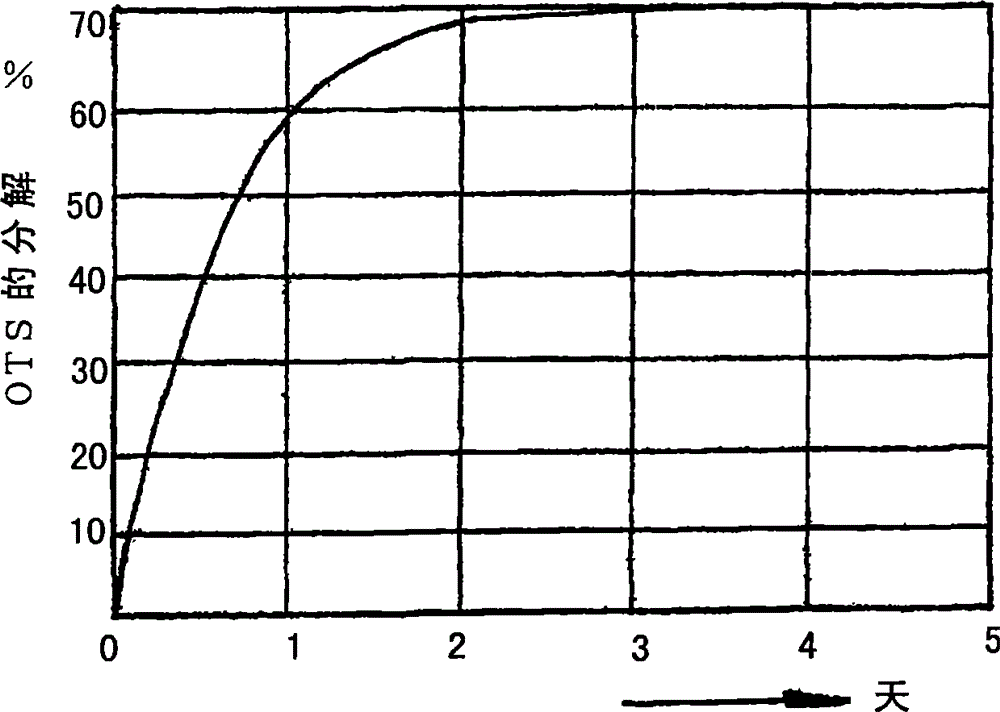

An organic material and biogas technology, applied in biochemical equipment and methods, biochemical cleaning devices, enzymology/microbiology devices, etc., can solve the problems of low gas yield, low decomposition percentage of organic dry matter, etc. Low, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] figure 2 A schematic diagram of a device for generating biogas according to the invention is shown. In the preferred embodiment, the biogas reactor 10 comprises an outer vessel 12 which is preferably cylindrical in the central part and conical towards the ends in the upper part 14 and the lower part 16 respectively. Inside the outer container 12 is housed an inner reservoir 18 which is cup-shaped and is arranged at a substantially constant distance from the outer container 12 so as to form a surrounding inner reservoir 18 between the outer container 12 and the inner reservoir 18 The filling chamber 20. The outer container 12 as well as the inner reservoir 18 are preferably made of steel, however, embodiments made of other materials such as plastic or the like may also be implemented. In this embodiment, the upper edge of the inner reservoir 18 serving as the overflow lip 22 is inserted into the upper portion 14 tapered towards the upper side to a depth such that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com