Gas Tank

A gas cabinet and gas technology, applied in the field of variable-capacity gas cabinets, can solve the problems of inability to continuously and finely adjust, gas storage speed, and gas discharge speed to be accelerated or slowed down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

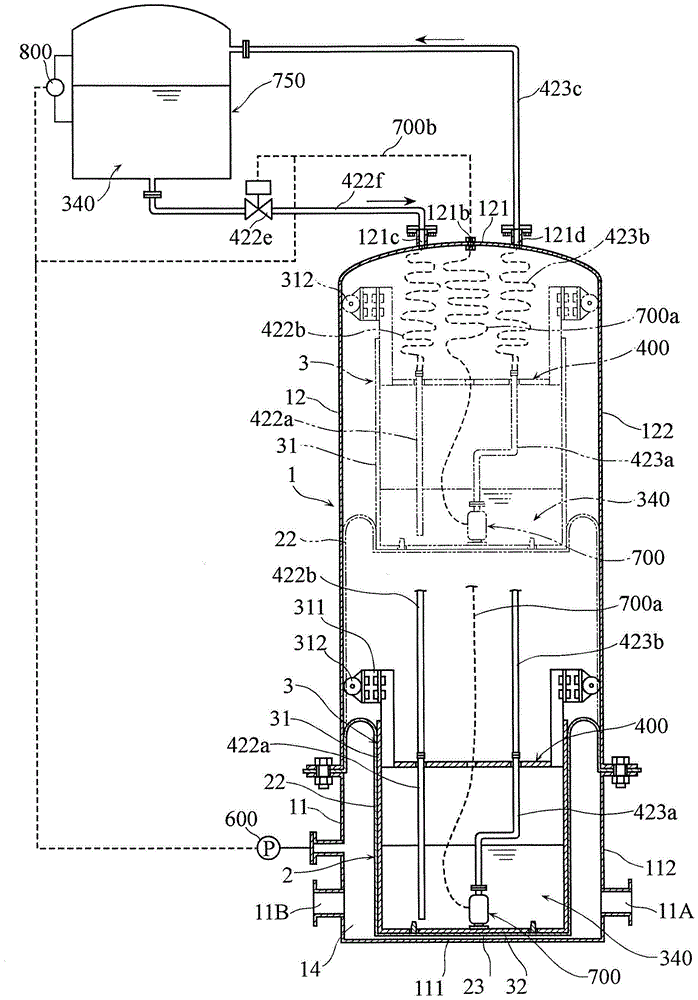

[0127] Hereinafter, preferred embodiments of the present invention will be specifically described with reference to the drawings.

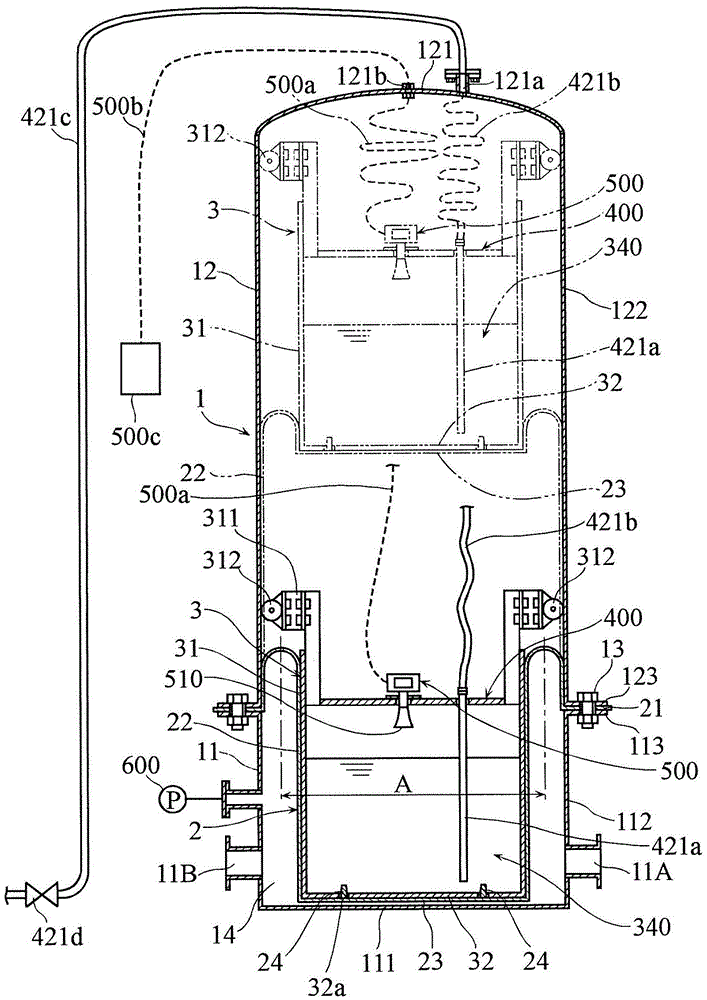

[0128] figure 1 A gas tank according to the first embodiment of the present invention is shown. Such as figure 1 As shown, the gas cabinet of the first embodiment includes a gas cabinet body 1 , a diaphragm 2 and a piston 3 .

[0129] The gas tank main body 1 has a lower cylinder 11 and an upper cylinder 12 which are integrally combined to thereby have a cylindrical container shape. The lower cylinder 11 has a disc-shaped bottom wall 111 and a cylindrical side wall 112 extending upward from the outer peripheral wall of the bottom wall 111 . An annular first flange 113 is integrally provided on the outer periphery of the upper end portion of the side wall 112 . Near the lower end of the lower cylinder 11, a gas inlet 11A and a gas outlet 11B are provided. At the middle position of the lower cylinder 11, a pressure gauge 600 is installed. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com