Locating laser anti-counterfeiting compound film and manufacturing method thereof

A technology of laser anti-counterfeiting and manufacturing methods, applied in the field of plastic packaging materials, can solve the problems of difficulty in fully guaranteeing the quality of finished products, easy generation of waste products, and short time, and achieve the effects of eliminating adverse effects, ensuring the quality of finished products, and good barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (Example 1, positioning laser anti-counterfeiting composite film)

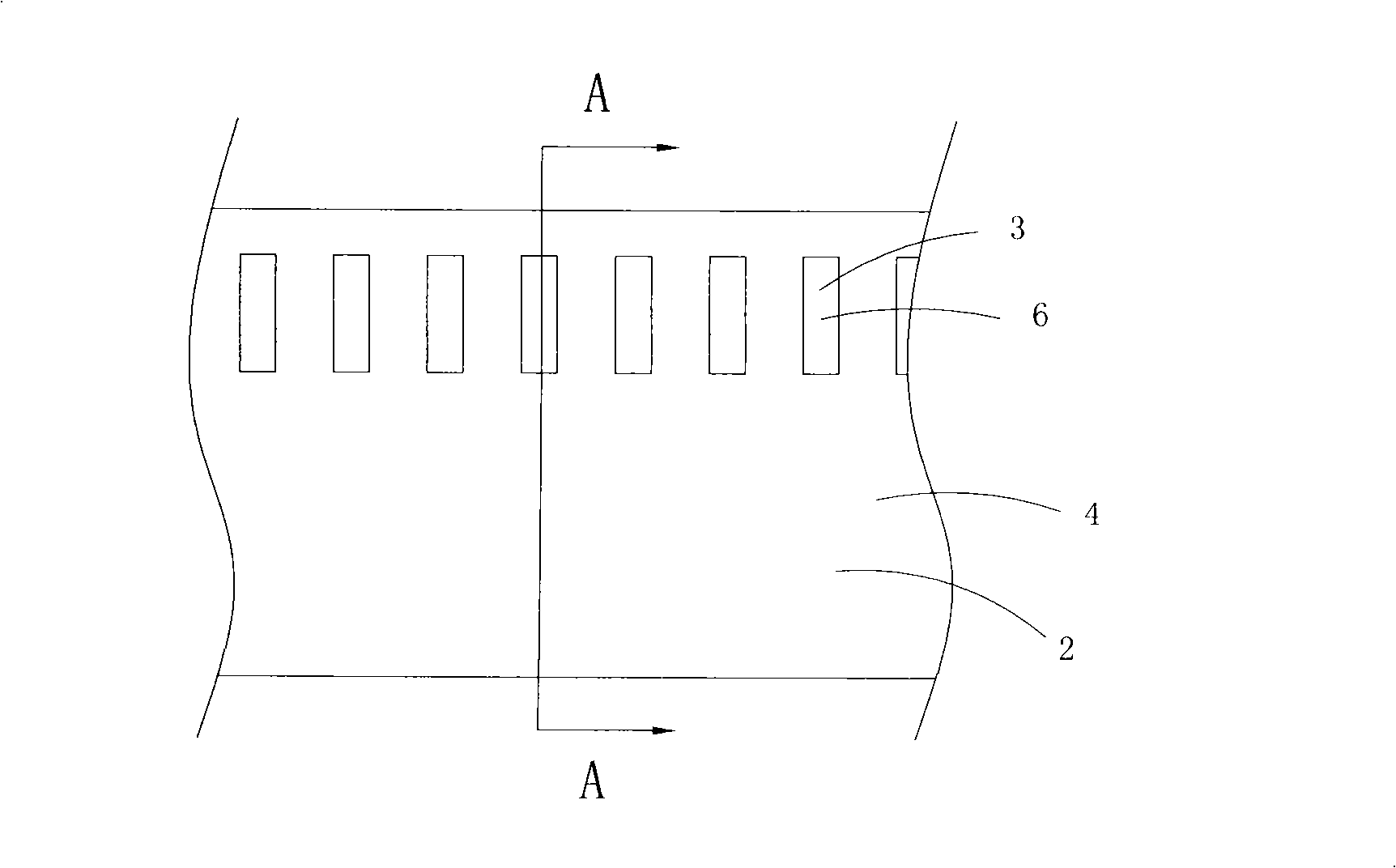

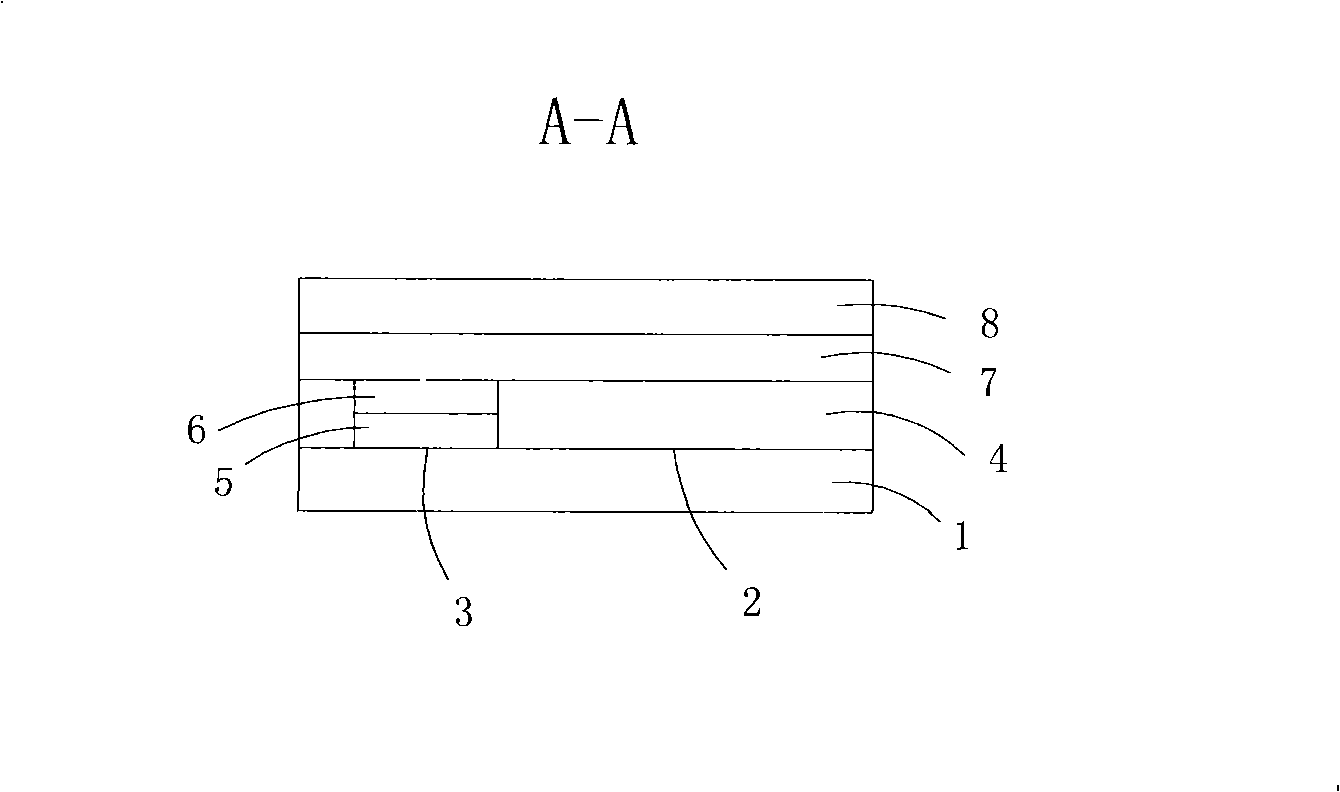

[0033] figure 1 and figure 2 A specific embodiment of the product of the invention is shown, wherein figure 1 is a structural schematic diagram of the first structure of the product of the present invention; figure 2 yes figure 1 The sectional view of the positioning laser anti-counterfeiting composite film along line A-A is shown.

[0034] See figure 1 , this embodiment is a positioning laser anti-counterfeiting composite film, which has a printing layer 1, and the printing layer 1 is provided with a printing area 2 and an adhesive area 3, and the printing area 2 is printed with a preset ink text layer or Ink pattern layer 4, the first adhesive layer 5 is coated on the adhesive area 3, and the laser anti-counterfeiting layer 6 is adhered on the first adhesive layer 5; the ink layer 4 of the printing layer and the laser A second adhesive layer 7 is arranged on the anti-counterfeiting layer 6 , a...

Embodiment 2

[0036] (embodiment 2, the manufacturing method of positioning laser anti-counterfeiting composite film)

[0037] This embodiment is the manufacturing method of the positioning laser anti-counterfeiting composite film described in Embodiment 1, which has the following steps:

[0038] 1. Prepare the laser transfer film and the printing layer 1 with the laser anti-counterfeiting pattern, the laser transfer film includes the base material and the laser anti-counterfeiting pattern layer 6 arranged on the base material; the printing layer in the present embodiment is a PET layer;

[0039] ② Position printing on one side of the printing layer and dry the ink used for printing, thereby forming a printing area 2 with an ink layer 4 and an adhesive area 3 without an ink layer on the printing layer; when drying the ink, control the drying Baking temperature is 60±5℃;

[0040] ③ On the adhesive area 3 of the printing layer 1, apply glue only on the adhesive area 3 by positioning the glue...

Embodiment 3 to Embodiment 4

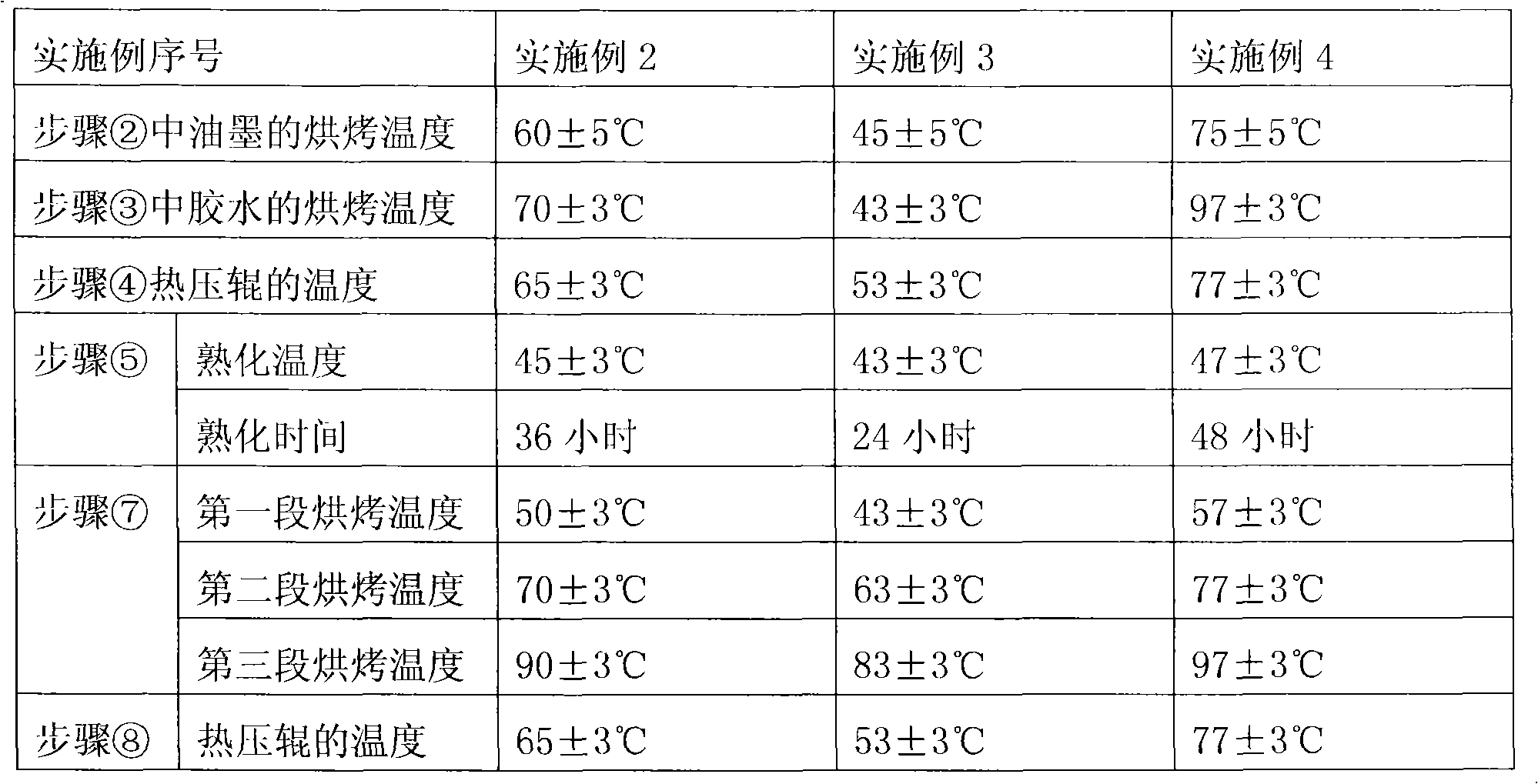

[0049] (embodiment 3 to embodiment 4, the manufacturing method of positioning laser anti-counterfeiting composite film)

[0050] Embodiment 3 and Embodiment 4 are basically the same as Embodiment 2, except that the process parameters in the process steps are different, and the specific process parameters in each embodiment can be found in Table 1.

[0051] Table 1

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com