Fluid bearing device

A fluid bearing and bearing sleeve technology, applied in the field of fluid bearing devices, can solve the problem of limited improvement in machining accuracy, achieve the effects of realizing machining cost, avoiding reduction of coaxiality, and ensuring moment rigidity

Inactive Publication Date: 2010-11-10

NTN CORP

View PDF4 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Correspondingly, it is necessary to further process with high precision the inner peripheral surface of the bearing member forming the radial bearing gap and the outer peripheral surface of the shaft member. Difficult, in addition, there is a limit to improving machining accuracy in normal machining

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

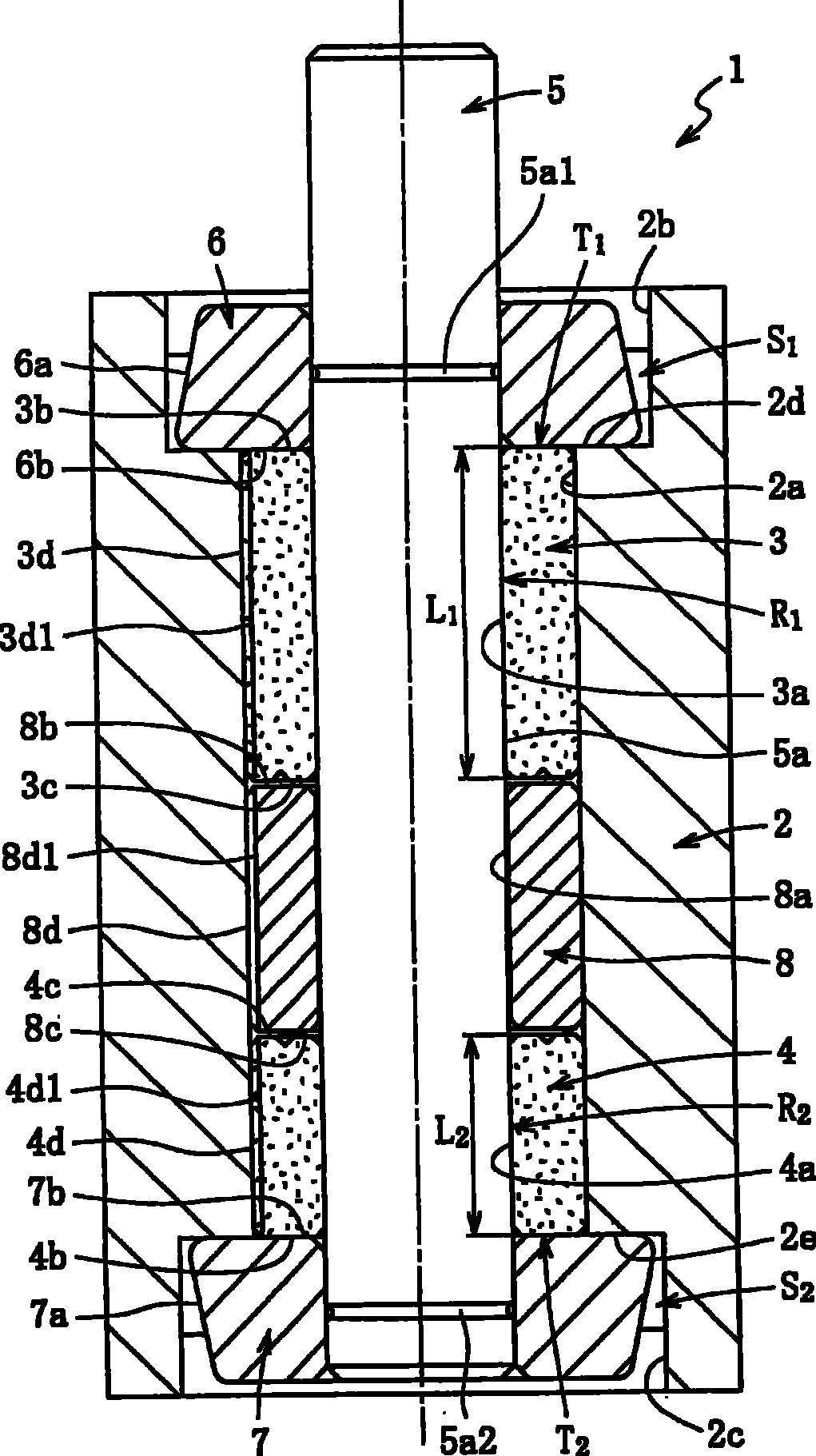

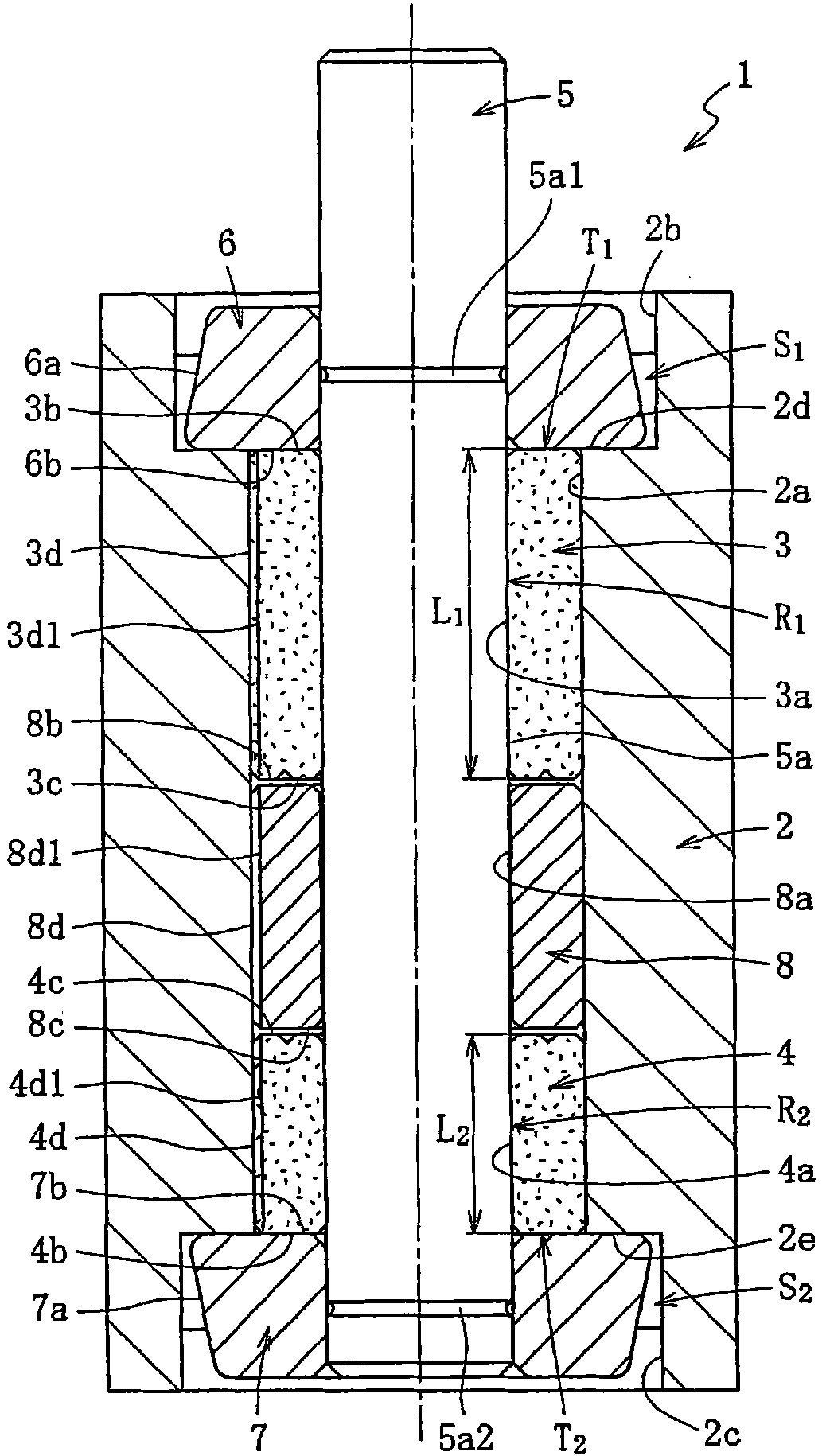

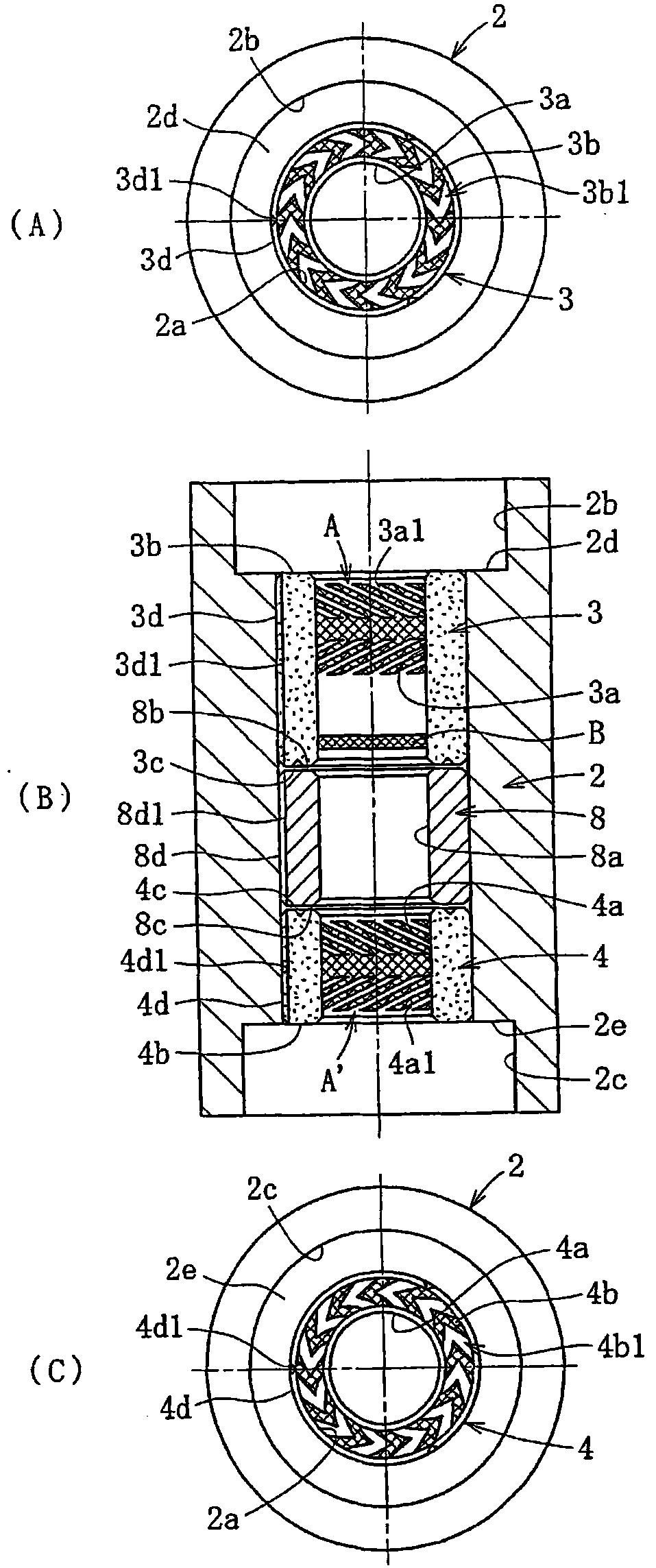

The present invention provides a fluid bearing device which has excellent moment rigidity and an improved working efficiency in assembling and parts control, and in which a bearing sleeve can be easily manufactured. A plurality of bearing sleeves are axially disposed in the fluid bearing device. The bearing sleeves (3, 4) are so formed that their axial lengths are different from each other.

Description

fluid bearing device technical field The invention relates to a fluid bearing device. Background technique In the fluid bearing device, the shaft member is rotatably supported by an oil film formed in a bearing gap. The fluid bearing has the characteristics of high-speed rotation, high rotation accuracy, and low noise. In recent years, its characteristics have been effectively used in information equipment such as HDD, FDD and other disk devices, CD-ROM, CD-R / RW, DVD-ROM / RAM It is widely used as a bearing for spindle motors on optical disc devices such as MD, MO, etc.; or as a bearing for fan motors mounted on personal computers (PCs) for heat source cooling. For example, in a fluid bearing device incorporated in a spindle motor of a disk drive device such as an HDD, both a radial bearing portion that supports the shaft member in the radial direction and a thrust bearing portion that supports the shaft member in the axial direction are sometimes composed of dynamic press...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16C17/10F16C17/26H02K7/08

Inventor 堀政治户田正明日比建治山本哲也

Owner NTN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com