Waste disposal during pit mining

A waste and mine technology, applied in open-pit mining, solid waste removal, ground mining, etc., can solve the problems of limited waste storage space and undesired

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

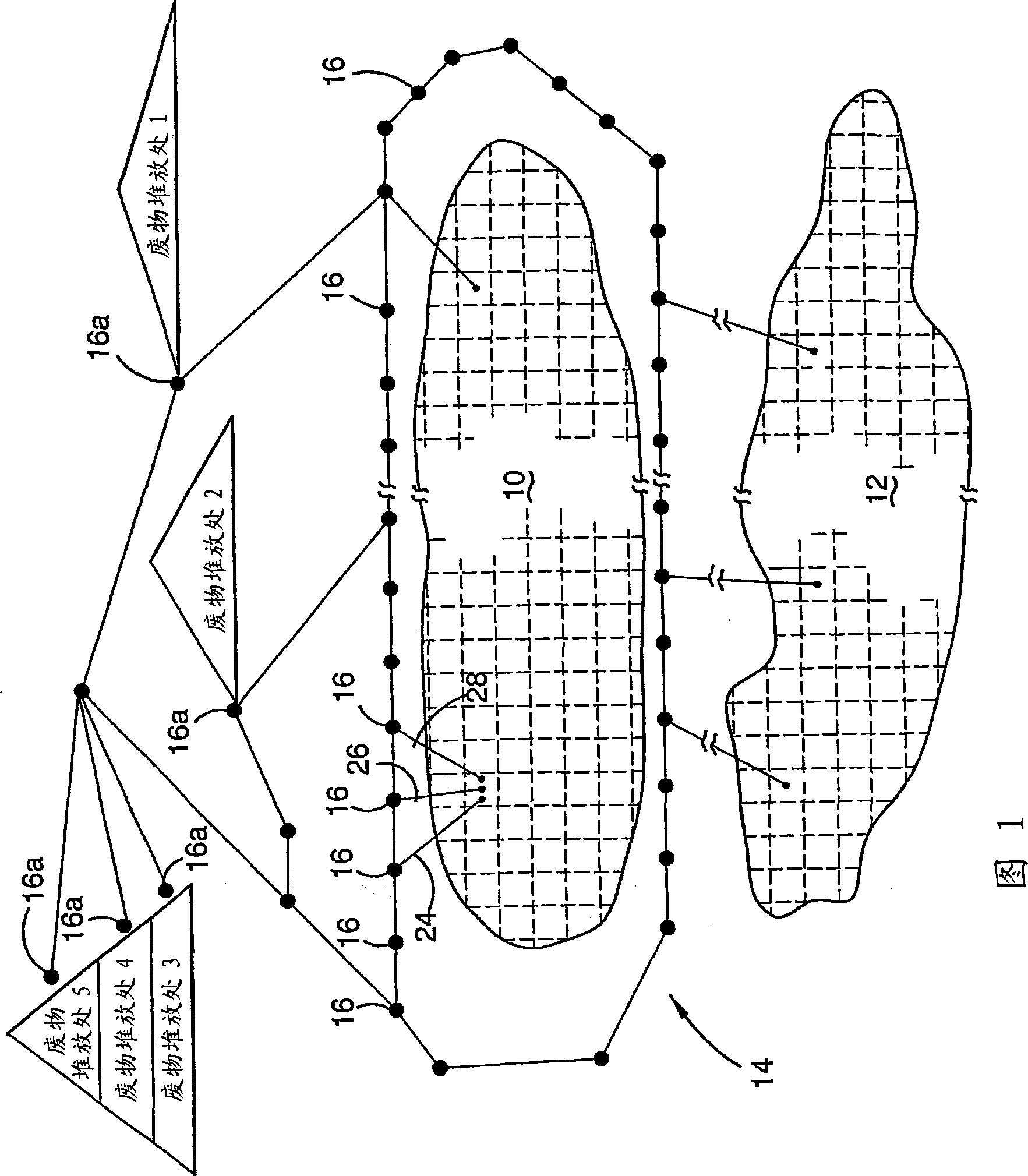

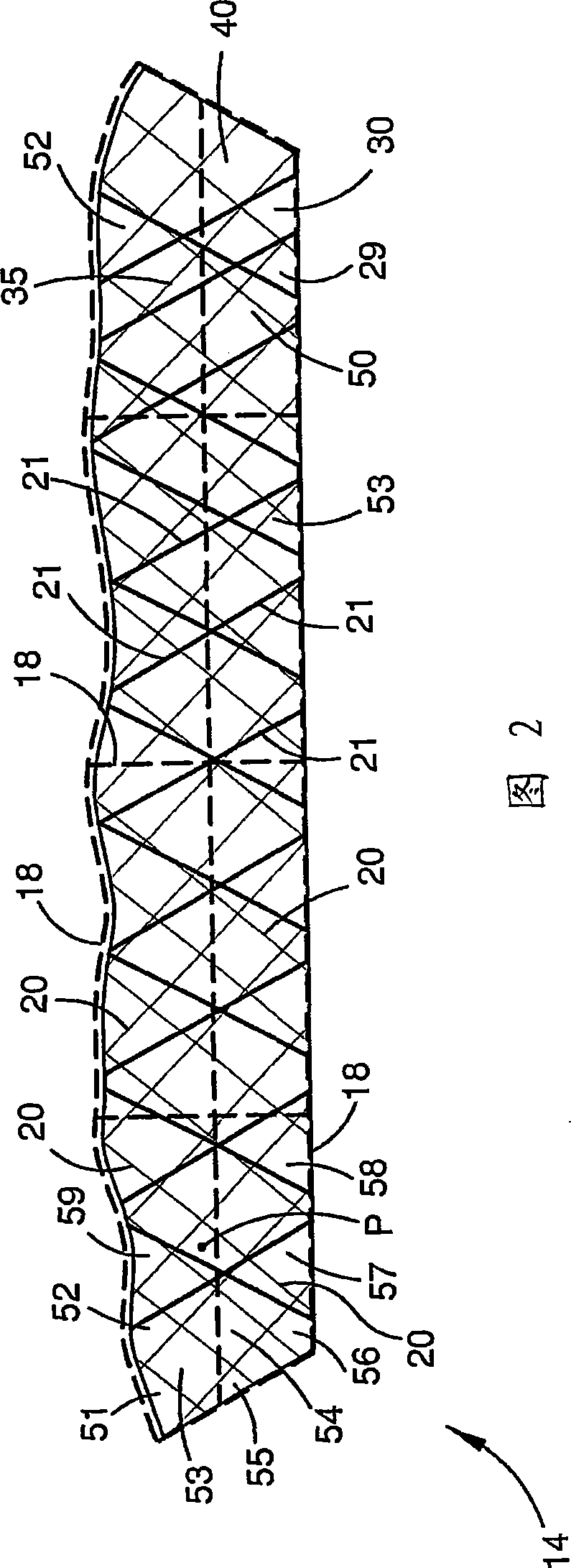

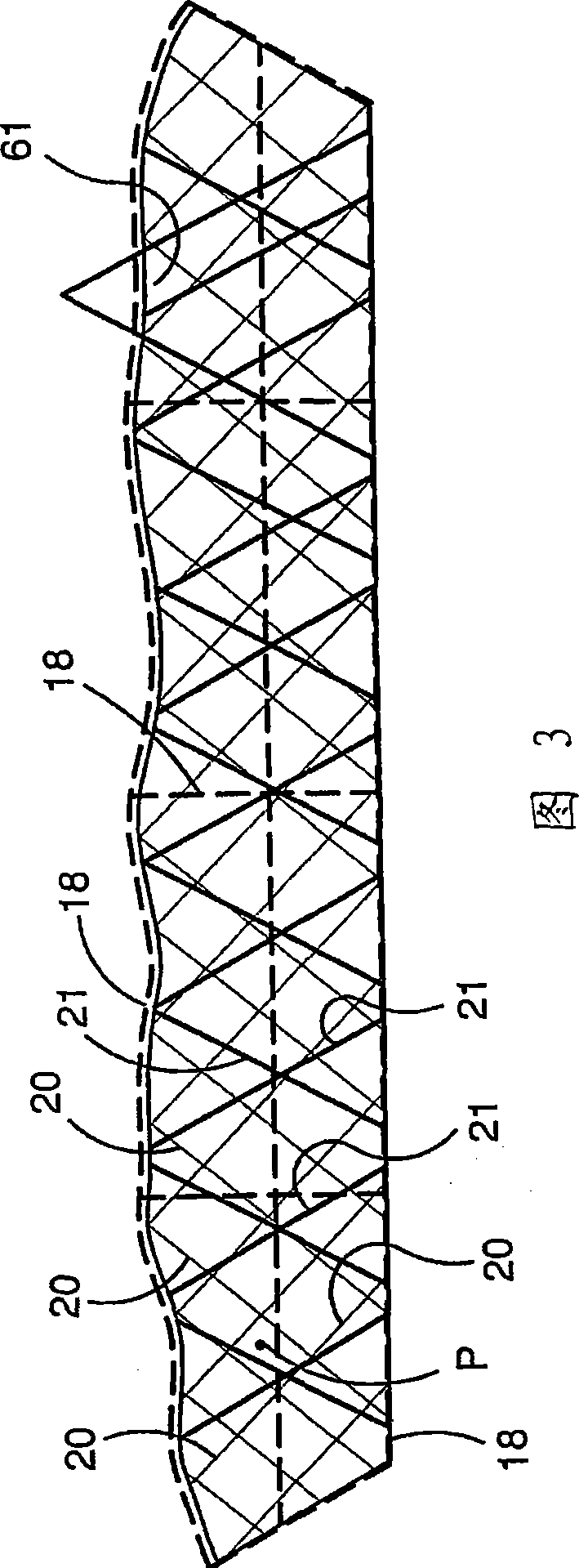

[0038] Critical mine plan optimization involves determining when to schedule mining of ore blocks (or aggregates) in an orebody throughout the operational life, taking into account all geotechnical gradient constraints and mining and processing capacity constraints. A typical mining plan is determined as a block model that divides the mine (ie, the area where the material is mined) into blocks that generally include between 10,000 and 20,000 blocks or aggregates. It is generally determined that the optimum limit surface mining range for the mixed mine operation is determined through all the block models that have been input by the user. These ranges are used to limit the set of blocks to be considered in constructing detailed annual plans for the extraction of raw materials. Various block models are grouped into aggregates so that the user has a measure of control over how many such aggregates there will be. The preferred structures in these aggregates are inherited from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com