Lithium plate machining device

A processing device and lithium sheet technology, which is applied in the field of automatic roll processing devices, can solve the problems of difficult forming and stripping, high overall cost, and low efficiency, and achieve the effects of improving quality consistency, reducing labor intensity, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

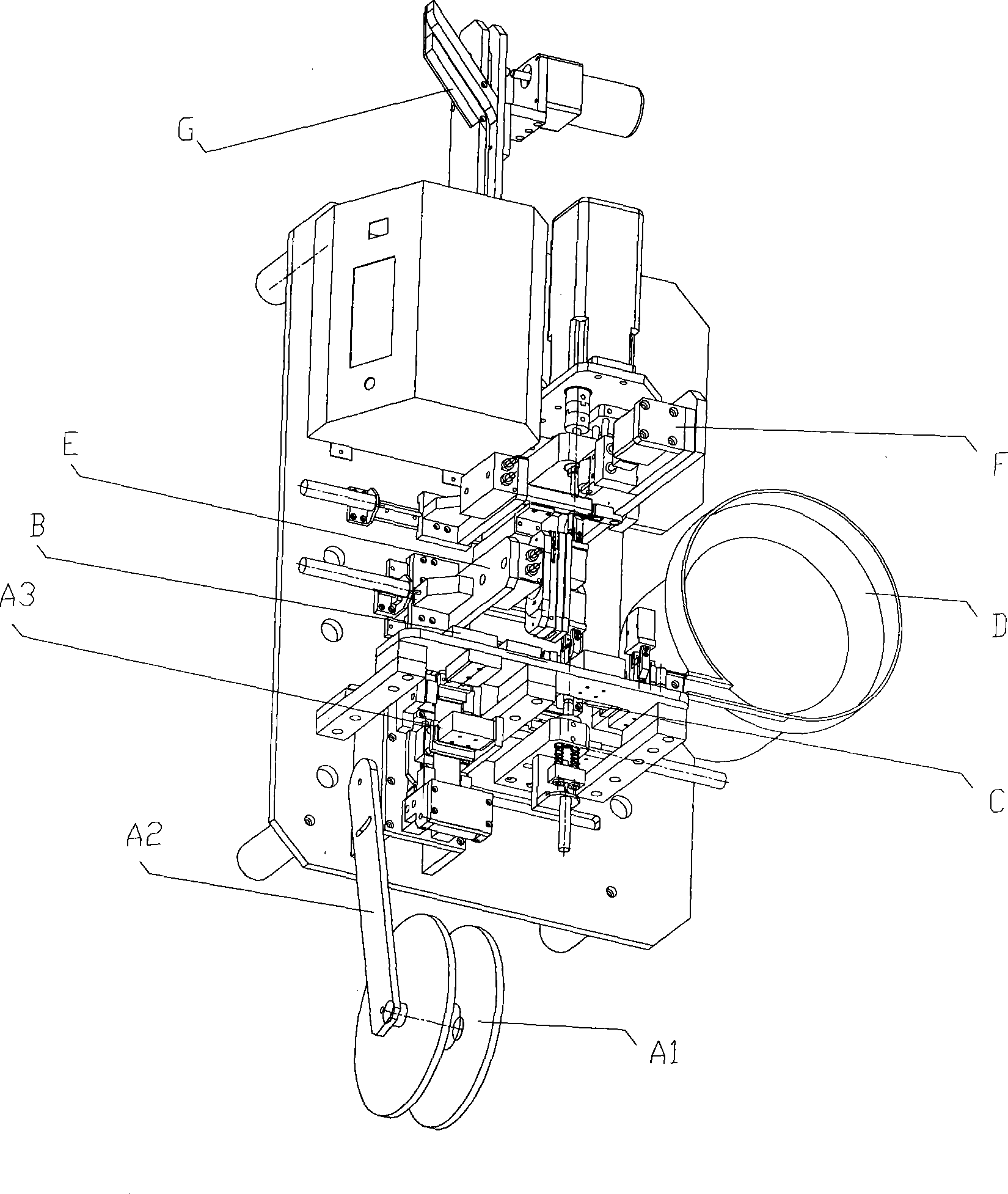

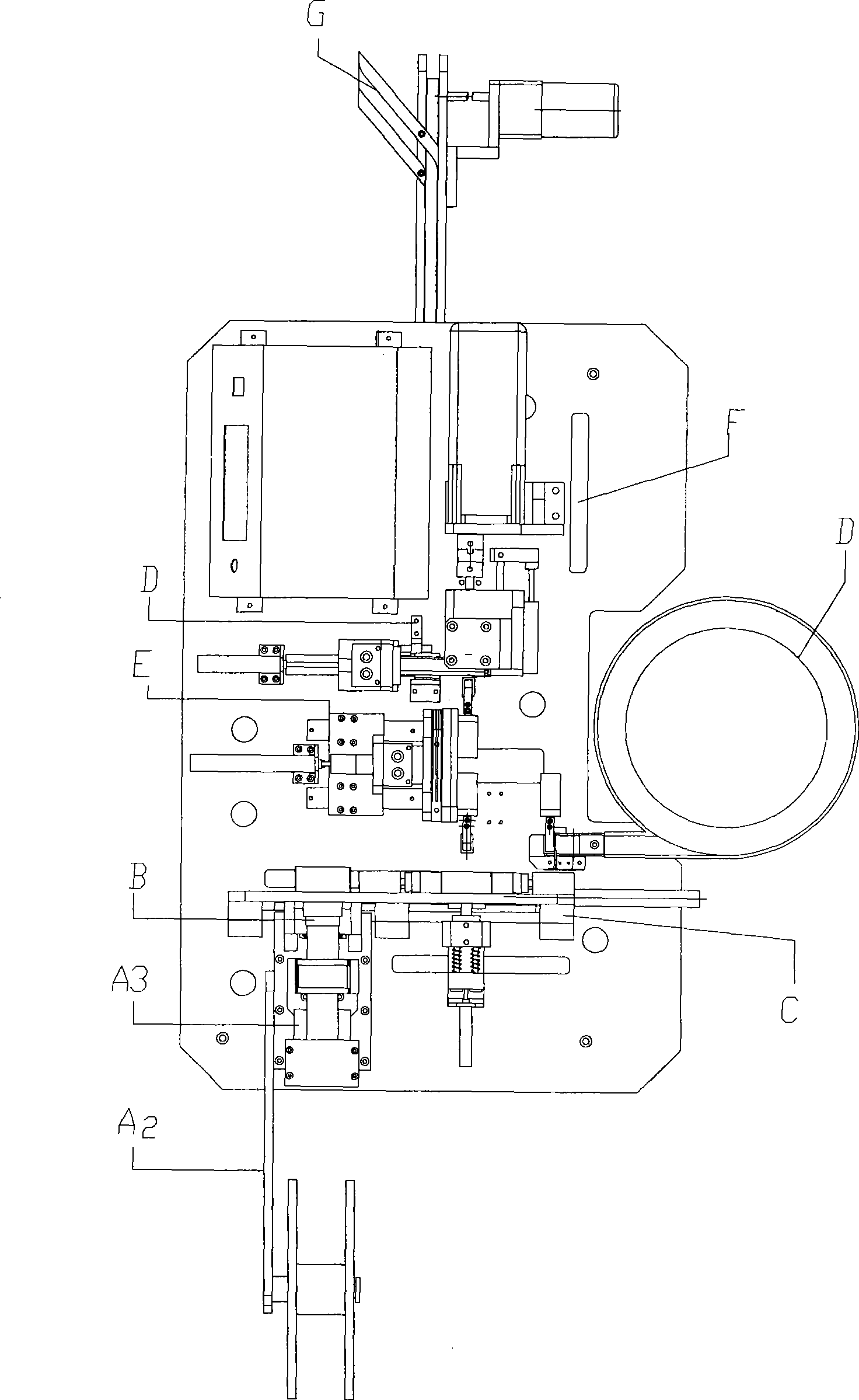

[0012] The gist of the present invention is to provide a lithium sheet automatic processing equipment with high degree of automation and high production efficiency, which is applied to the manufacture of lithium batteries with metal lithium as the negative electrode. When manufacturing lithium batteries, the metal lithium Li sheet, which is the negative electrode active material of the battery, must be attached to the inside of the battery steel case or rolled into a certain shape before being placed inside the battery case. However, because the metal lithium sheet is very soft, it is easy to bond. on various materials. Therefore, when making the lithium battery, it is difficult to mechanize and automate the cutting, crimping, positioning, and shelling of the negative metal lithium. The problems to be solved in the present invention are: use methods such as gas (liquid) dynamic and mechanical transmission, cooperate with suitable molds and fixtures to realize the automation an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com