Compressed natural gas distributor

A technology for compressing natural gas and distributors, which is applied in gas/liquid distribution and storage, equipment for loading into pressure vessels, container filling methods, etc. To achieve the effect of improving the inflation effect and inflation speed, reducing the connection parts, and eliminating the need for joint components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

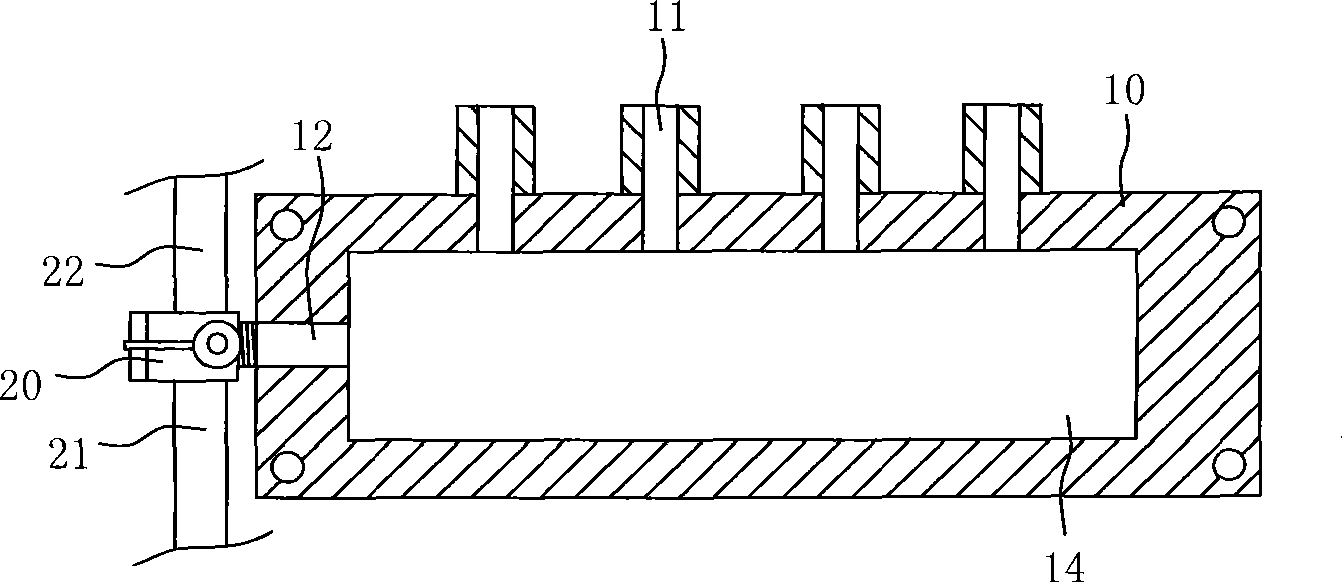

[0008] Such as figure 1 , 2 As shown, a compressed natural gas distributor, the distributor 10 is hollow, and the distributor 10 is provided with a plurality of interfaces 11 directly connected to the gas cylinders 2 respectively through pipelines; the interfaces 11 are evenly spaced in the hollow distribution On one side of the device 10, the interface 11 is connected to the gas cylinders 2 through pipes, so that the distributor 10 can directly and individually inflate each gas cylinder 2, which improves the inflation effect, and at the same time reduces the joint parts and saves the joint components. ,cut costs.

[0009] The distributor 10 is also provided with a passage 12, the inner end of the passage 12 communicates with the cavity 14 in the distributor 10, and the outer end of the passage 12 is connected with the air inlet pipeline 21 and the air outlet pipeline 22 respectively. An integrated manual cut-off valve type overcurrent protection valve 20 is provided at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com